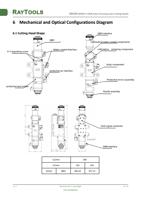

BM109 SERIES 1.5KW Auto-Focusing Laser Cutting Heads

4 Beam Adjustments and Focusing

4.1 Beam Adjustments (QBH Interface)

Cutting quality in a great extent depend on whether the lens are in the middle. If the lens are not in the

middle, the laser beam may contact with the nozzle or the inner wall to produce high temperature deformation.

Lens centering operation should be considered when nozzle is replaced or the cutting quality is decreased.

Lens centering of BM109 laser cutting head can be finished by adjusting collimating mirror, X-Y direction.

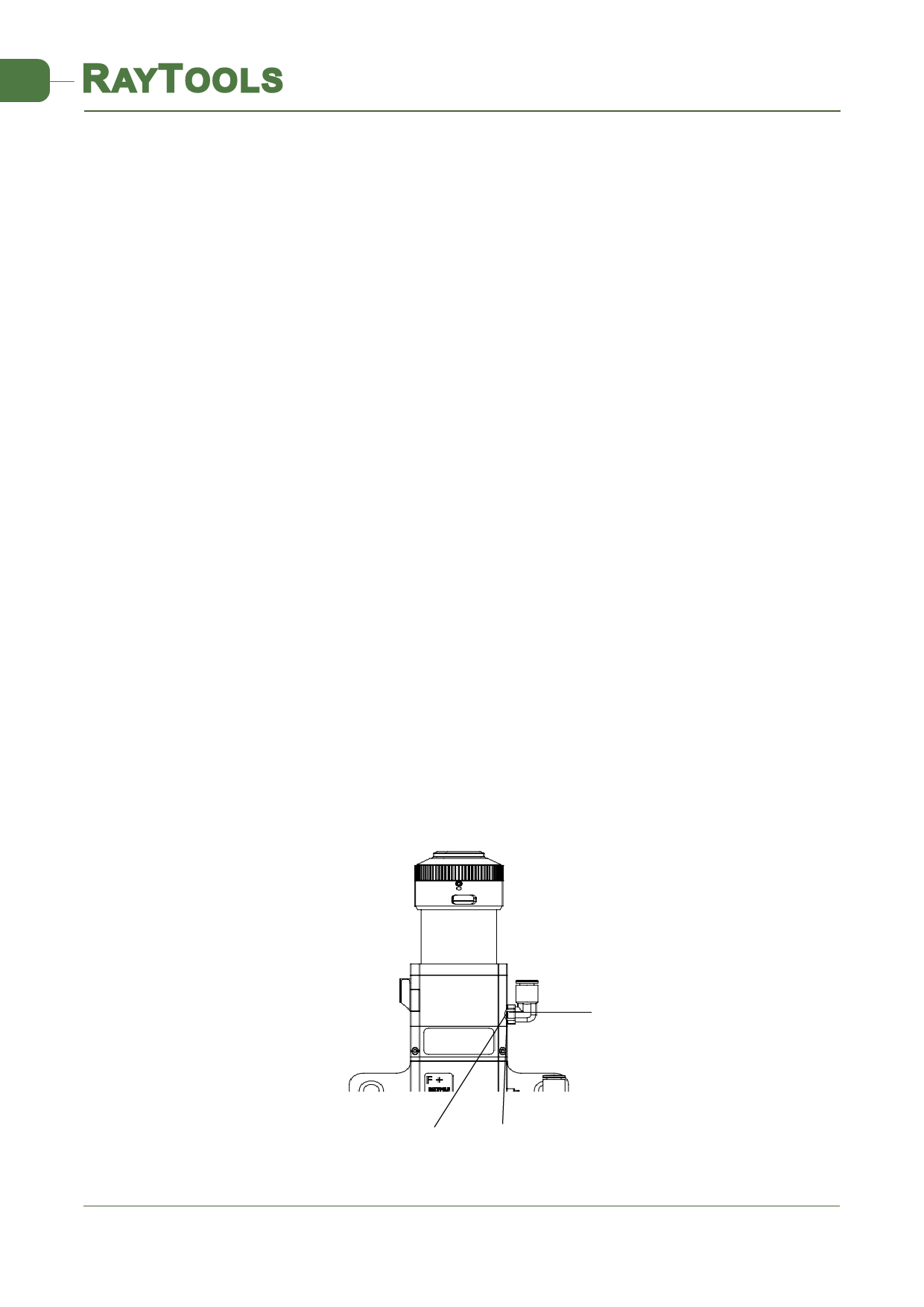

The adjusting screw is located on the top of the cutting head as shown in Figure 5.1. Using inner hexagon

spanner can loosen or screw the adjusting screw until the beam is located in the middle of the nozzle. Make

sure the laser beam output from the center of nozzle. A method commonly used tape dotting method:

Take a piece of transparent tape flattened directly below the end face of the nozzle center hole;

Open the inner guiding red light of the laser, find and observe the position of nozzle center that the red

light in the scotch tape relative to. Adjust the red light spot to the relative center of the nozzle by adjusting the

screw;

Next, open and adjust the laser generator at the range of 80W-100W and dot manually;

Tear off the tape and check whether the hole in the center of the nozzle;

Repeat the above steps to find the optimum relative nozzle center position of the beam;

This centering operation requires a series of adjustments, which is the basic operation of general laser

centering.

X-Y regulating screw

Figure 5.1 - beam centering

V1.0

RayTools AG © Copy Right

14 | 24

www.raytools.net