Creating a New ICC Profile Guide

Original On Flexi Help

http://flexihelp.saicloud.com/en/Content/4_Production/Color/Color%20Profiling/Creating%20a%20

New%20ICC%20Profile/Before%20you%20Begin%20making%20an%20ICC%20Profile.htm\

Before you Begin making an ICC Profile

Before you print test swatches, consider the following factors to maximize the

quality of your color calibration:

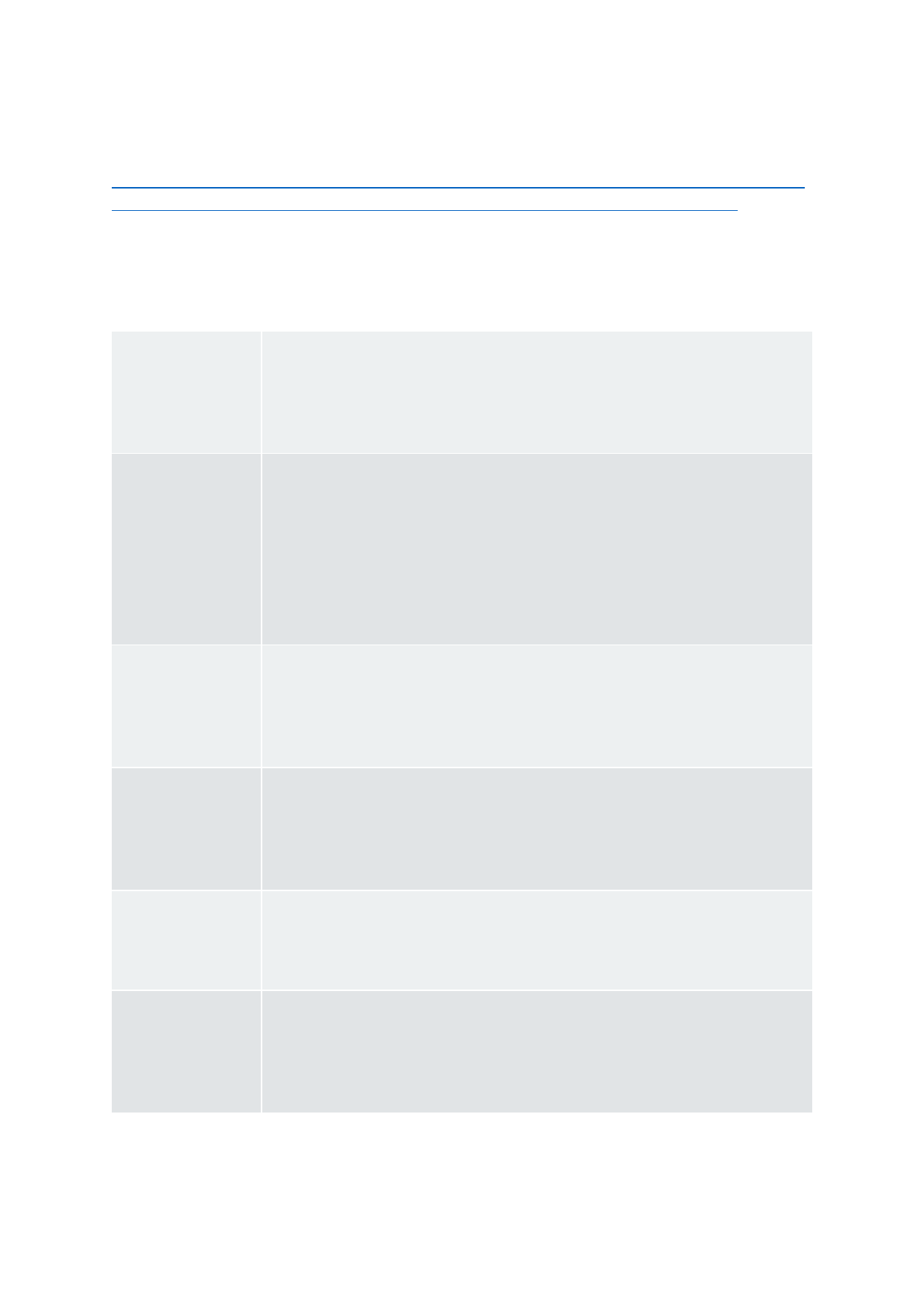

Ink

Each printer is designed with specific kinds of ink;

therefore you should use the manufacturer-

recommended inks. Also, make sure the inks are filled

and properly primed as instructed by the manufacturer.

Media

Media is the most important part of the ink and media

interaction. This interaction between the ink and media

coating affects every aspect of print quality, including

color accuracy, vividness and durability, as well as the

sharpness of your print. If the ink and media are not

properly matched, potential problems include bleeding

and smearing.

Resolution

Resolution measures the number of dots per inch printed

by the printer. Changing the resolution affects the dot

placement and the amount of ink laid down on the

media by the printer.

Environment

Humidity and temperature affect the drying time for a

print, which affects the ink and media interaction. A

longer drying time can cause ink bleeding or intentional

ink mixing.

Print mode

For the best results, calibrate using the printer's highest

quality print mode. Using the quality mode will reduce

banding.

Print heads

Print heads should be properly primed and all nozzles

should be firing. The heads also need to be in alignment.

Consult the printer manufacturer's documentation for

instructions.