BM115 SERIES 6-12KW Laser Cutting Head User Manual

fixation method. Please refer to corresponding instruction of fiber interface.

WARNING: The optical components must be dust free and all dusts must be cleaned

before use. The fiber shall be horizontally inserted into fiber interface to prevent dust from

entering the interface and falling on the surface of the lens. Upper limit in the fiber before

fixing the laser head.

2.5 Fiber Insertion and Interface Direction Adjustment

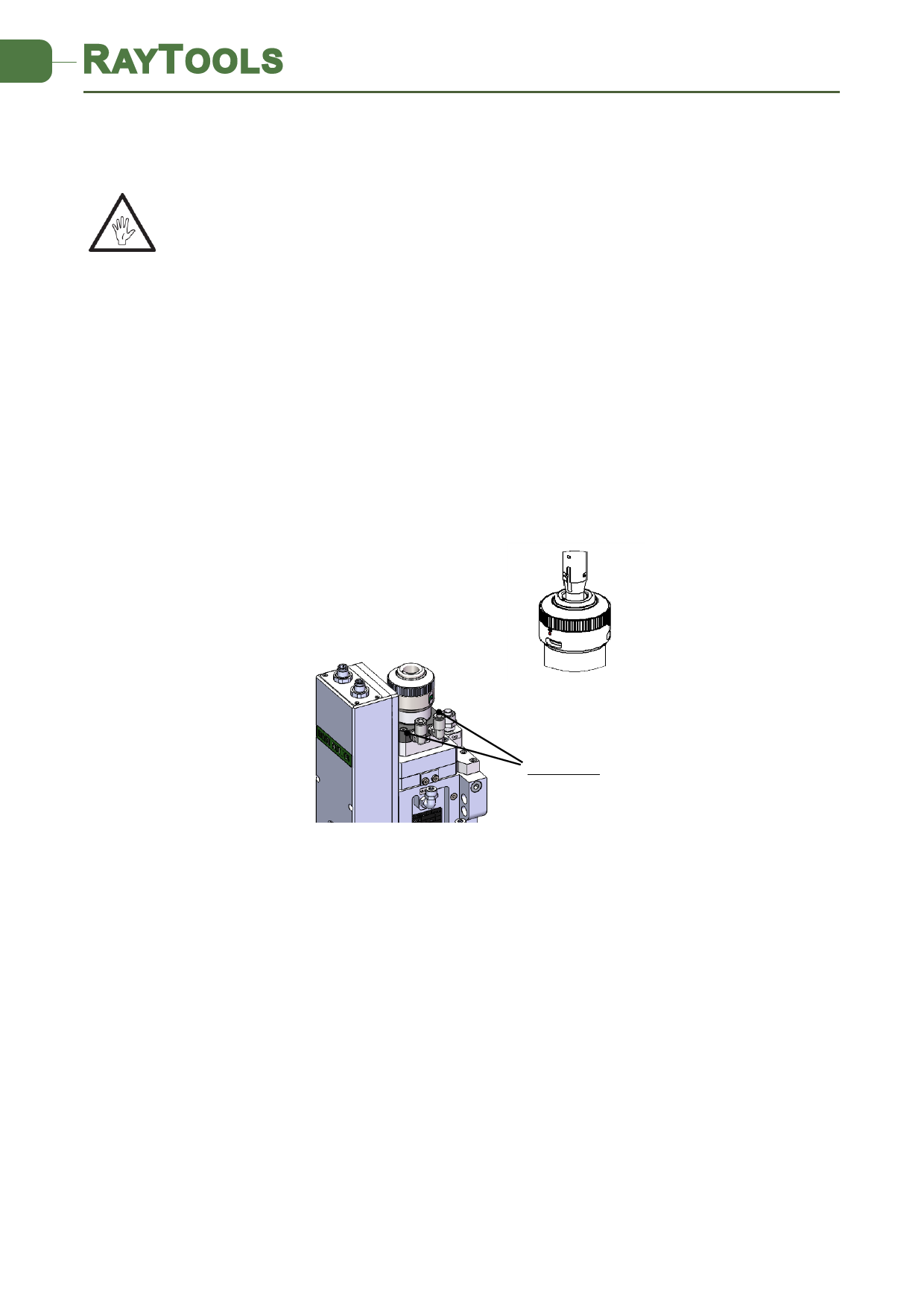

The fiber insertion way is described as below by example of QBH.

Firstly, to align the red point at the end of the QBH interface to the red point of the handwheel;

Then remove QBH dustproof cover and ensure the red mark of fiber end aligned to red mark on

QBH of cutting head when you insert the fiber end straightly to bottom of QBH interface of

cutting head. Then turn the QBH handwheel clockwise. It is in place when you hear the "Da"

voice, then pull the handwheel up and turn clockwise to end. (see Figure 2.4)

Locking screw

Figure 2.4— Fiber insertion to QBH

If the red mark on fiber is too far away from the red dot on laser head interface when the fiber

connector is inserted into the interface causing an out of alignment insertion, you can refer to

steps below to adjust the position of fiber interface on laser head for solving the problem. As

shown in Fig. 2.4, unscrew the 4 locking screws of the position of the part icon with a wrench,

rotate the QBH interface and screw the locking screws after the red mark is in place.

The fiber insertion way is described as below by example of QD (LLK-D).

Firstly, to remove the dustproof cover and align the location pin of fiber end to U type slot of QD

interface. To pull the external edge downward and insert fiber straightly to bottom then release.

Check if there is any loose by slightly rotating fiber. (see figure 2.5)

8 | 27

www.raytools.ch