8.运行机器,以电动方式启动(以保证油正常循环机头内部有油),观察油位线的位置,当

油 位低于下红线位置时,停止机器等待压力放空确保压力归零,拆卸加油口,再次吧油位加到上红

线位置,安装加油口,正常运行。

9.当保养完毕后,清理门板上的空气防尘棉,可用压缩空气进行吹扫。

10.运行半小时到 1 小时后检查一次,确保无误。

2. Accessories and tools required for air compressor maintenance

1. Accessories need, special lubricating oil for high pressure air compressor, oil filter, air filter, oil.

2. Tools required: oil filter wrench, No. 10 hex socket wrench, No. 19 wrench, No. 41 wrench (available with pipe

pliers), adjustable wrench, waste oil drum, gloves.

3. Maintenance sequence

1. First shut down and close the switch. If it is normally used before shutting down, wait for a while and wait for

the oil temperature to decrease before operating.

2. Empty the air, check that the pressure gauge is zero, and then start the operation.

3. Open the door plank, finding oil and gas separation cylinder, oil discharge mouth, at the bottom of the barrel

of oil and gas separation inside the oil discharge port ball valves equipped with a plug wire, inner hexagon spanner

pull down with 10 after discharge the waste oil, close the valve when oil cannot eduction, open the switch, to point

the way to run a machine (running four to eight seconds press stop stop), close the switch, When the pressure gauge

on the oil and gas separation barrel returns to zero, open the valve again to release the remaining waste oil, and pour

the new oil at the end of maintenance.

4. Remove the oil filter, watch the arrow on the surface of the oil filter, confirm the disassembly direction for

disassembly (the oil filter has positive wire and reverse wire), if there is no oil filter wrench can be used, the oil filter

will overflow part of the oil when disassembly, you can pad it with a rag, pour a part of the new oil inside the oil filter

when the new oil filter is installed, and then tighten the installation.

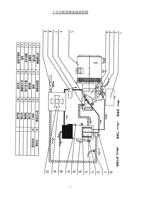

5. Replace the air filter. The position of the air filter can be seen from the internal diagram of the machine below.

6. Replace oil, tear down three pipe of the oil and gas separation barrel on your rod (removed to ensure the

gasholder without pressure), disconnect the line after the removal of yellow flange on the roof above the screw, the

screw loose flange, vertical pull out after out oil use blade oil glue scrape in the above things, scrape off the flange

head internal rust, ensure the installation of oil surface is smooth, Put the new oil into the position of the installation

of the top cover, installation in a diagonal way to tighten the screw, connected to the pipeline.

7. Close the valve of the drain port, open the refueling port above the oil port for refueling, observe the oil level

gauge, stop refueling when the oil reaches the position of the red line above, and tighten the refueling port (pay

attention to the sealing pad on the screw of the refueling port).

8. Run the machine, start it in electric mode (to ensure the normal circulation of oil there is oil inside the head),

observe the position of the oil level line, when the oil level is lower than the lower red line, stop the machine, wait for

pressure empting to ensure that the pressure returns to zero, remove the refueling port, add the oil level to the upper

red line again, install the refueling port, and run normally.

- 11 -