- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- Rollman-Industrial-Laminator

- RM-1520A User Manual.pdf

- Page 4 of 12

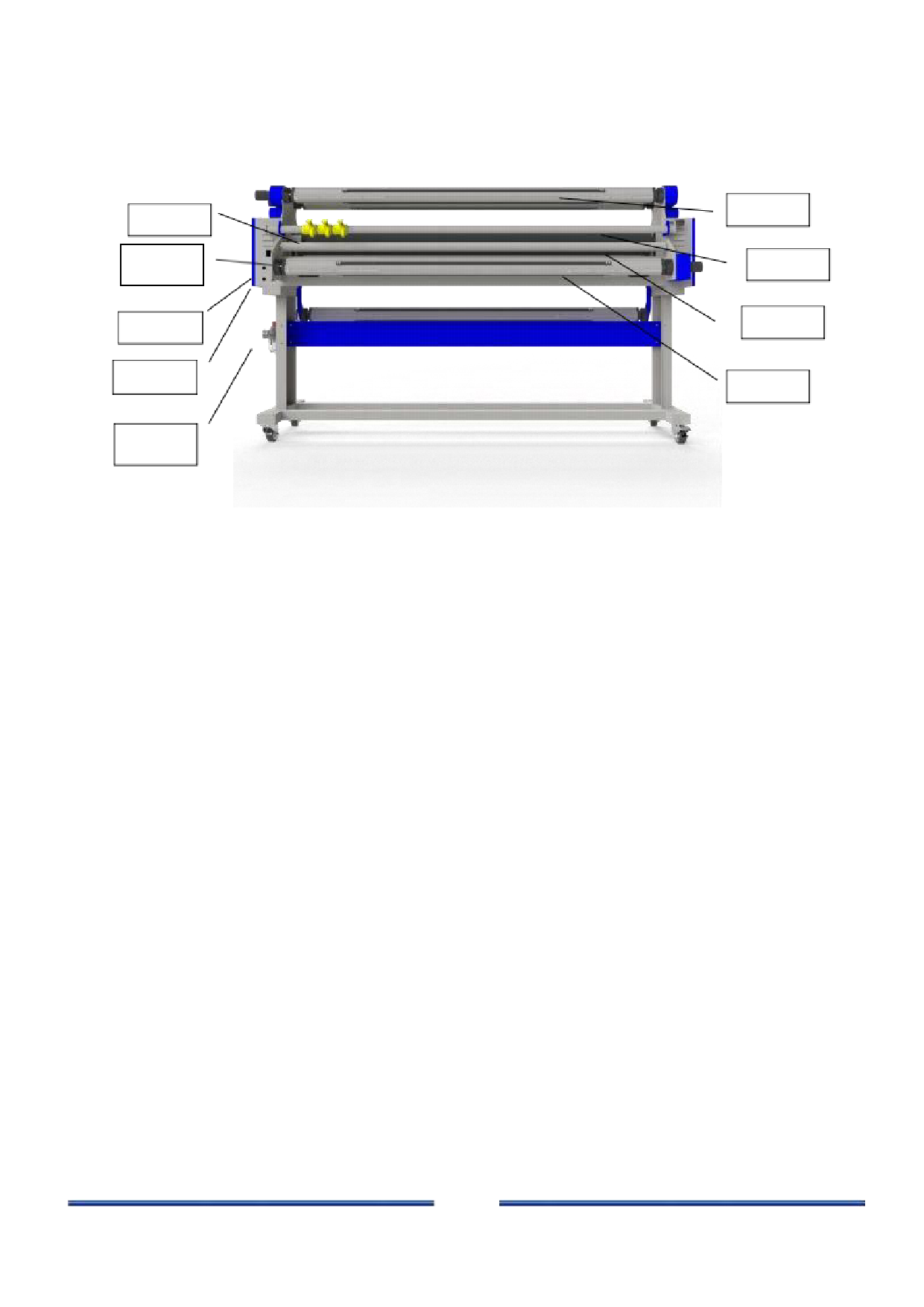

Cutting knife

Power

switch

Protective tube

socket

Pedal switch

Oil-water

separator

Rubber strip

Cutting-off tool

rod

Cutting-off tool

top rod

Finished product

collecting axle

Rubber roller: Top rubber roller and bottom rubber roller are the most important parts of the laminator, and they are made

of high-quality silicon, which has the features of high temperature resistance, wear resistance, corrosion resistance and

getting rid of sticking.

Picture placing axle, film placing axle, lining paper collecting axle, finished product collecting axle: The core axle

consists of the aluminum rod, aluminum head, bearing, rubber strip and other components, with the outer diameter

controlled within 3 inches to facilitate assembly and disassembly of regular films in the market (such as yellow backing film,

ground film and other film products). In the process of operation, the rubber strip plays the role of increasing the friction to

ensure that no slide, loosening, too tight condition and other conditions happen while laminating.

Rubber roller lifting button: The pneumatic switch has two gears of upward and downward movement. In the case of air

vented in the equipment, the former gear can make the top rubber roller lift, and the latter can make the top rubber descend

to tentatively lock the air inflow and output. The cylinder adopted by this equipment is SDA50-30, enabling the lifting

height of the top rubber roller reaching over 28mm. The air circuit system is adopted to synchronize the lifting and

descending process of the top rubber roller, which plays a crucial role in terms of pressure.

Emergency shutdown switch: When the machine is in an emergency or dangerous state, the emergency shutdown switch

can be used to cut off the power supply and stop the operation of the equipment to ensure the safety of people and

equipment.

Cutting knife: Using the cutting knife can longitudinally cut the blank edge while laminating.

Tightening handle: Through 4 core axles that have been adjusted beforehand, the tightening handle can be used to adjust

the tightening force. Users can directly turn the handle clockwise to turn up the tightening force, and turn the handle

counterclockwise to turn down the tightening force.

Photoelectric switch: It has the function of "anti-pinch hand". The function is on in the process of operation by default, and

it will pause when obstacles are detected.

2