- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- Rollman-Industrial-Laminator

- RM-1520A User Manual.pdf

- Page 3 of 12

1. Equipment overview

RM-1052A full-automatic single-sided laminator is a kind of new-type instant laminating

equipment integrating functions of laminating and cutting. It adopts rubber rollers made of high-

quality silicon, with good thermal stability and a long service life . It has a totally new mode of

laminating, allowing the right and left material rods to alternate with each other, as well as the

function of automatic detent, applicable to post-printing materials, stereotyped display board,

packing board, vehicle film, floor film, reflective display board, banner advertisement, show

window display material, desk film, etc ., and compatible with all kinds of cold laminating film in the

market (including backing paper film, macromolecule cold laminating film, etc .) . The machine is easy,

stable, efficient and energy-saving to use. Due to its innovative structure, it has been welcomed by users

since it was launched.

1.1 Product parameter

Maximum laminating width

Maximum laminating speed

1600mm

12m/min

Heating temperature

Heating power

Normal

temperature -70℃

2000W

Maximum laminating thickness

28mm

Rubber roller lifting mode

Pneumatic lifting

Top rubber roller diameter

Bottom rubber roller diameter

Rubber roller material

130mm

110mm

Silicone

Motor power

Input voltage

Equipment size

120w AC motor

220V (110V

version is

customizable)

Package size

Equipment net weight

2140mm*710mm*

785mm

200kg

Heating time

5-10min

Packaging gross weight

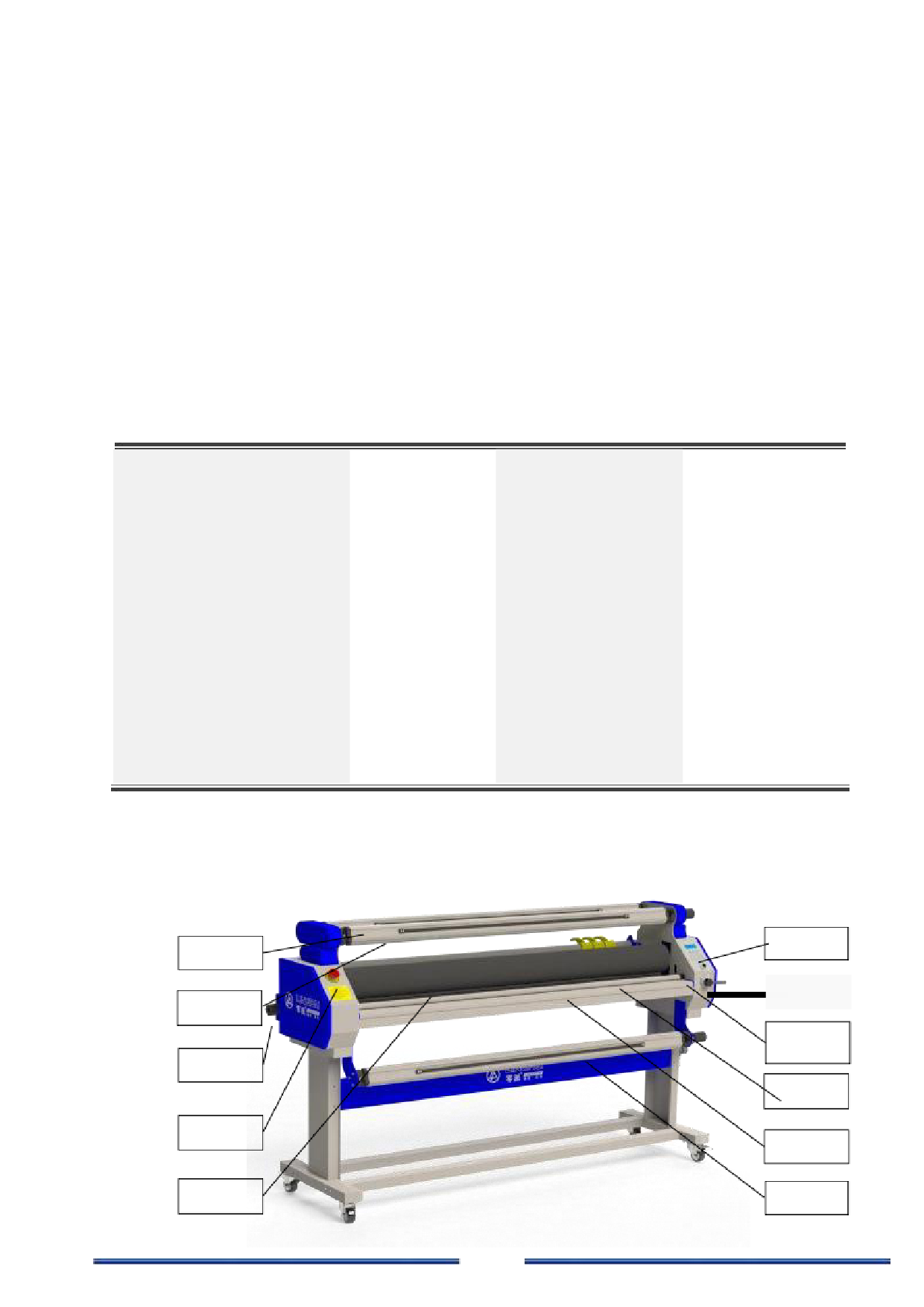

1.2 Product introduction

Film placing axle

Lining paper

collecting axle

Tightening

handle

Emergency

shutdown switch

Top rubber roller

1

Operation panel

Lifting button

Photoelectric

switch

Bottom

rubber roller

Smoothing

rubber roller

Picture placing

axle