- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- RAYCUT-Fiber-Laser-Machine

- RAYCUT Fiber Laser Startup Parameters.pdf

- Page 11 of 26

NB: ZERO FOCUS just means that the focus position is on the material surface.

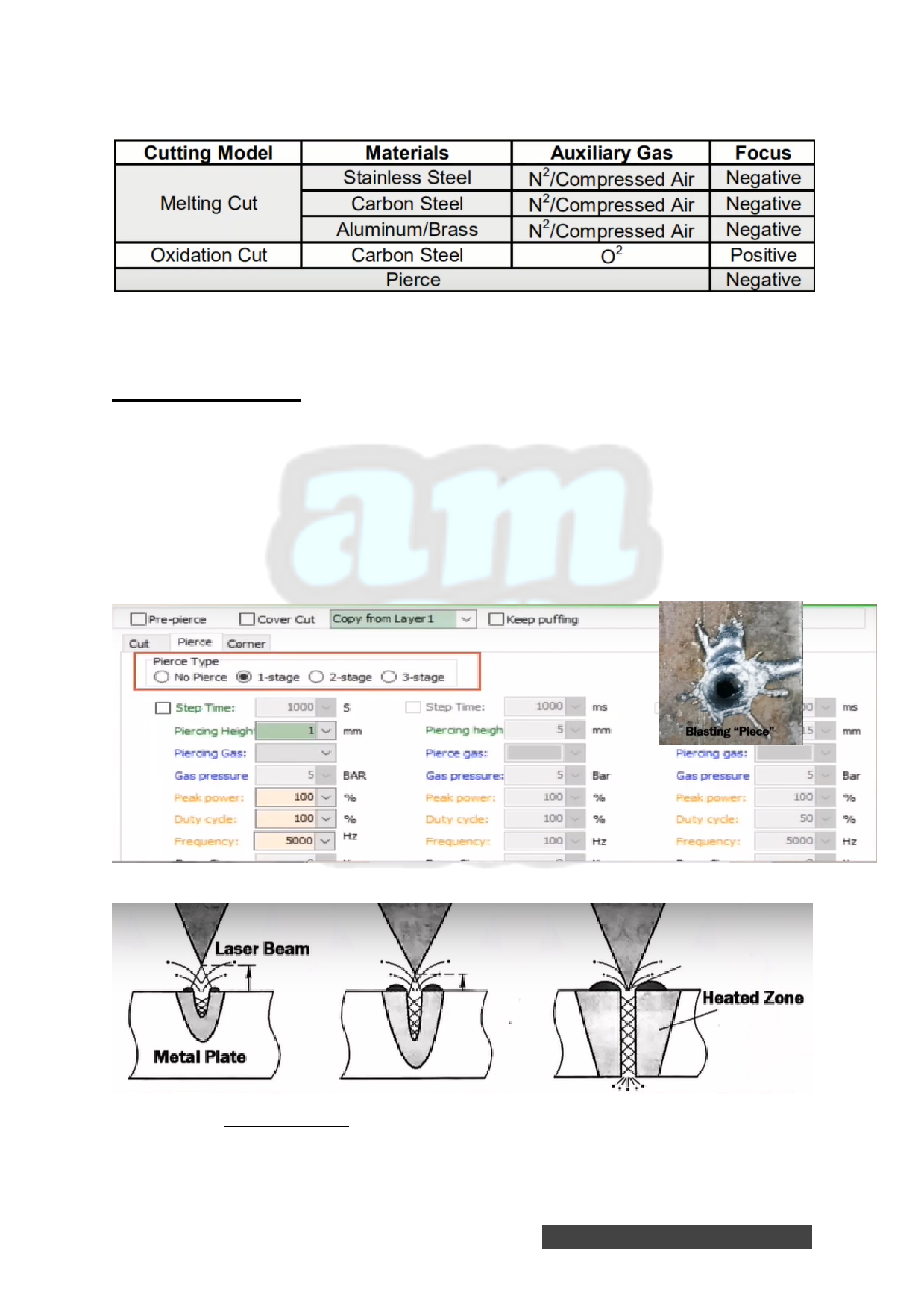

PIERCE SETTINGS:

Important hole cut through into the starting point of the material

1: Pre-pierce will help reduce over-burning as it will only cut after performing the

function, thus giving the laser head sufficient time to cool before it starts the next piece on

the job.

2: Nozzle height for pre-pierce should be higher than the cutting height

3: The total running time of the jobs is increased by the pre-pierce function as it has

to do this before any new contour and also a lot of errors are prone to occur.

The above is a blasting pierce which is not in multiple stages and the results are normally

like in the picture on the right. With the size of the hole being directly proportional to the

metal thickness.

BY NGONI CHIBVONGODZE