- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- RAYCUT-Fiber-Laser-Machine

- RAYCUT Fiber Laser Startup Parameters.pdf

- Page 10 of 26

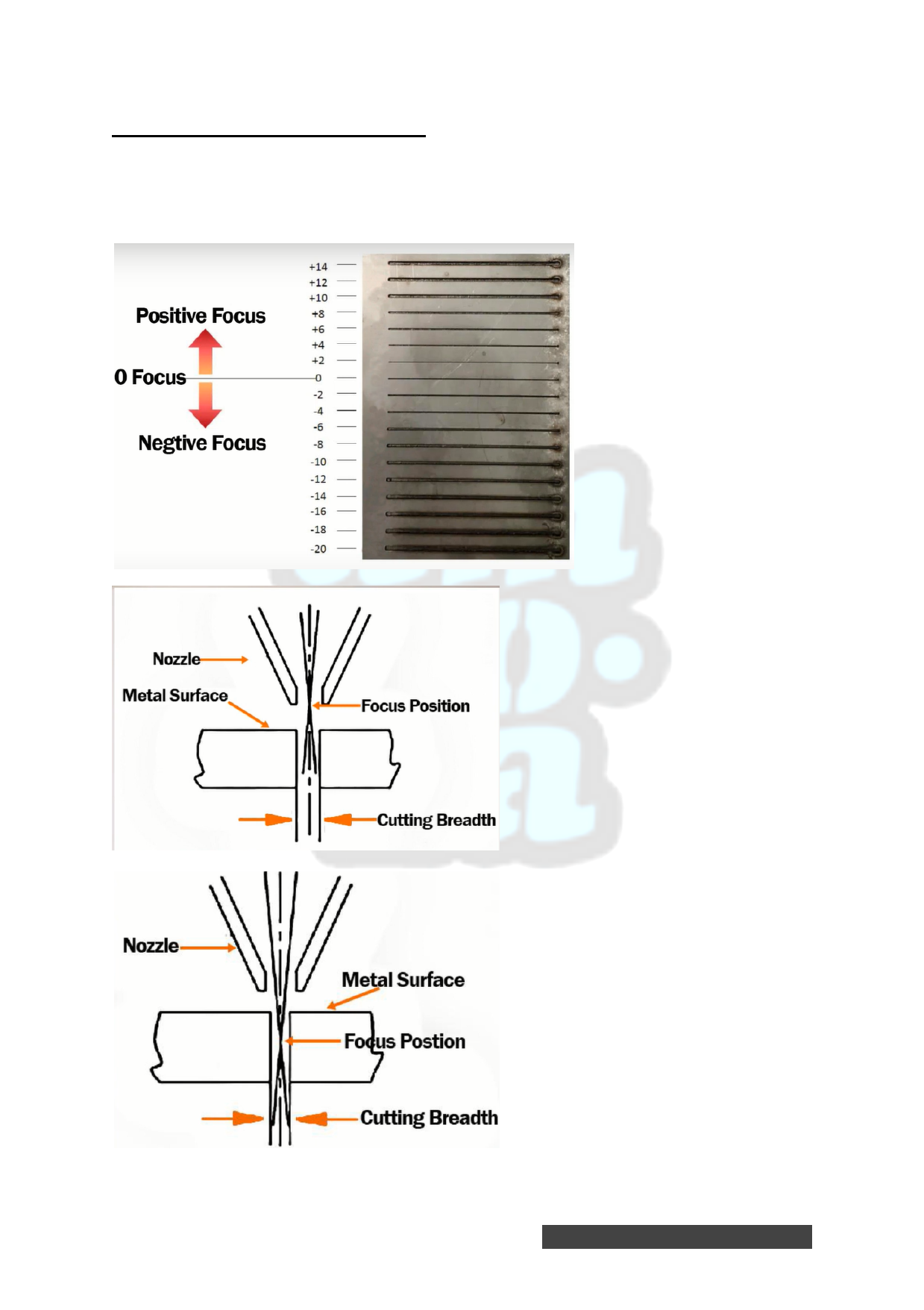

FOCUS POSITION SETTING:

This’s one of the key parameters in laser cutting and directly affects the laser

being able to cut through with good quality or not

As you can see here, the

more offset it’s from the

focus position, the wider

the cutting gap and

reduced cutting power.

POSITIVE FOCUS POSITION:

- Used for cutting carbon

steel with oxygen.

- Here the focus position is set

on top of the material so that the

heat can work hand in hand with

oxidation to cut through the

material.

NEGATIVE FOCUS POSITION:

- Used for cutting stainless

steel, brass, aluminium… with

compressed air or nitrogen as

auxiliary gas.

- The focus position is set

inside the material.

- Normally all the Pierce

values for focus position on any

material should be negative so that

the pierced hole can be as small as

possible.

BY NGONI CHIBVONGODZE