10. Application Functions

Electronic gears are generally used for the following purposes.

(1) When driving loads based on the user unit.

- You can give command based on the user unit, regardless of the encoder (motor) type.

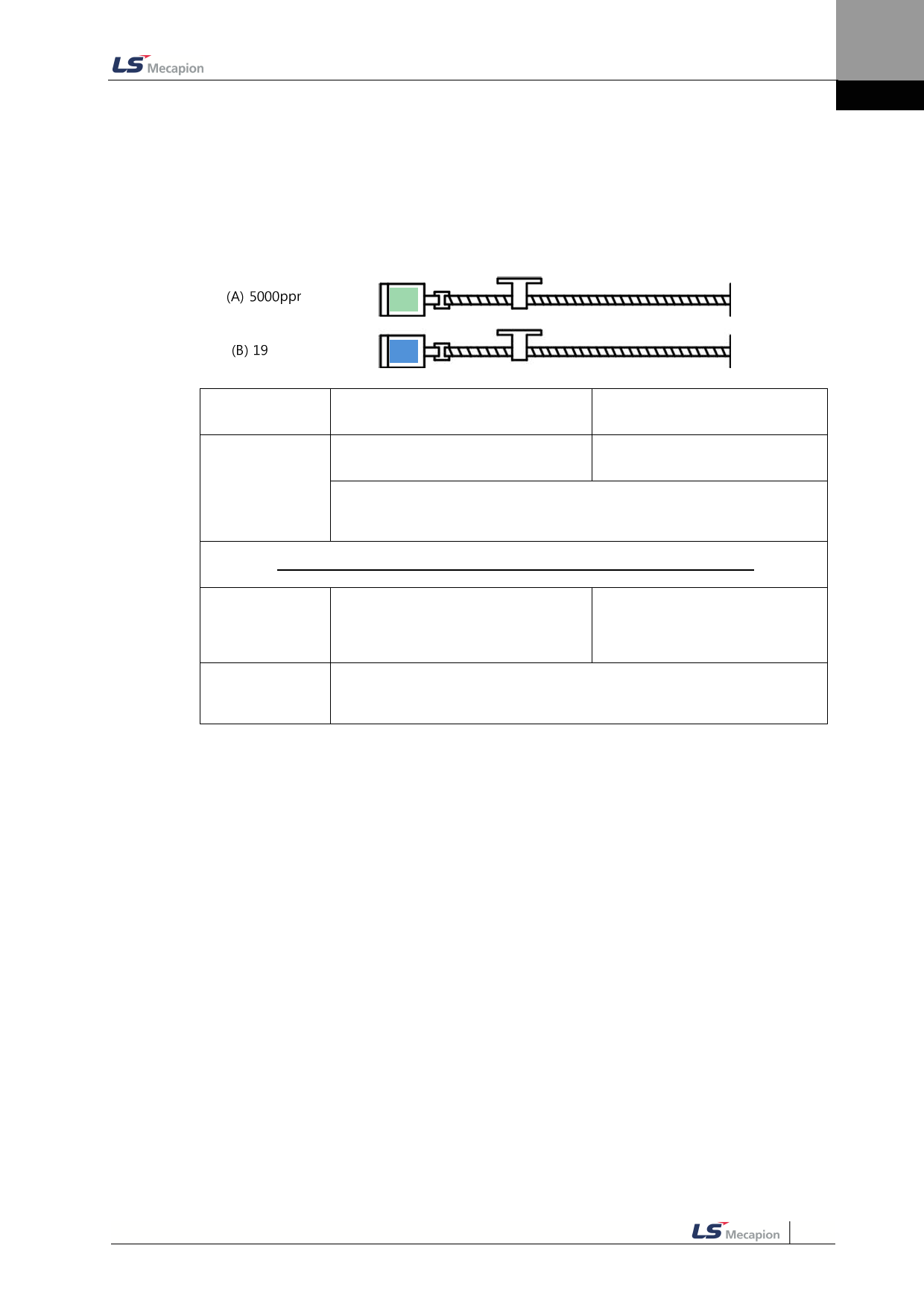

The table below shows comparison between 5000ppr encoder and 19bit encoder, when

moving 12mm using the same 10mm-pitch ball screw.

encorder

bit encorder

(A) 5000ppr Encoder

(B) 19bit (524288 ppr) Encoder

Without electronic

gear

5000*12/10 = 6000

524288*12/10=629145.6

Different commands should be given to each encoder (motor) when moving the same

distance

When giving command based on the minimum unit (user unit) of 1um(0.001mm)

Electronic gear

setting

Motor Revolutions =5000

Shaft Revolutions = 10000

Motor Revolutions =524288

Shaft Revolutions = 10000

With electronic

gear

You can give the same command to move 12000(12mm= 12000*1um) regardless of

the encoder (motor) type.

(2) When the output frequency of the host device and the drive’s input frequency are

restricted when driving a high-resolution encoder at a high speed

- A regular high-speed line drive pulse output unit has output frequency of around

500Kpps. The drive’s input frequency is around 1~4Mpps. For this reason, driving a

high-resolution encoder at a high speed restricts the output frequency of the host device

and the drive’s input frequenc. Electronic gears must be used to achieve normal driving.

10-19