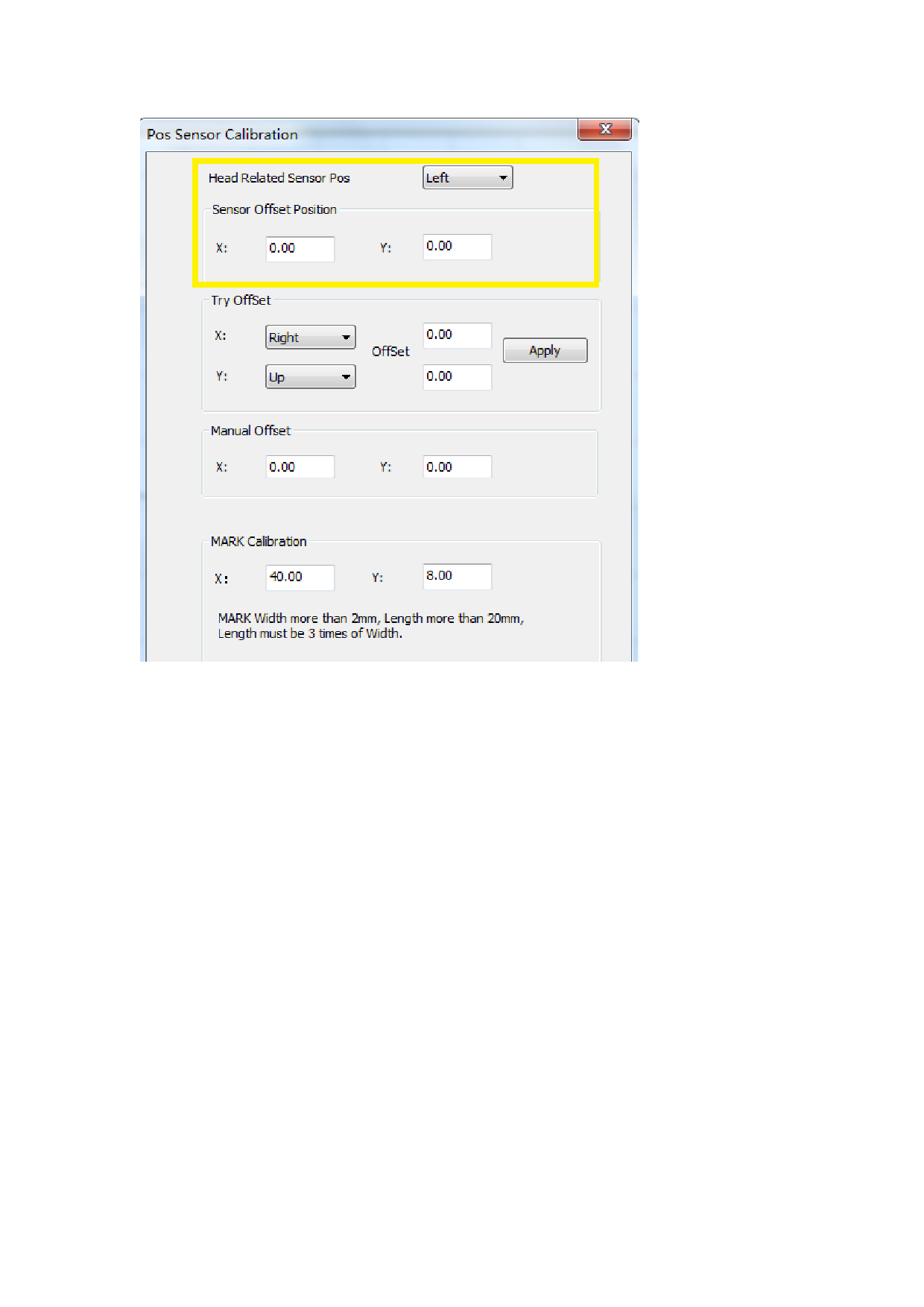

Method 2:

If the laser head has infrared beam design, the direct use of X and Y to measure

the deviation between the midpoint of the ruler and the red light of the sensor values,

at the same time through the relative position determination sensor light midpoint

position relative to red mark point, directly select the “left-top / right-top/ left-bottom

/right-bottom”; and the corresponding measurement value to fill out the"

corresponding position sensor offset, and the implementation of the "confirm" ,and

then close the position sensor calibration interface.

2:Fine positioning

Method 1:

On the left side of the drawing tools selected location "MARK" standard (below)

", then the MARK standard format for any position, and set the corresponding

processing parameters in the laser processing layer management interface, and then

use a piece of paper stuck on a piece of hard wood as the test object, put the

corresponding position in the format, and then click start processing, the software will

download the MARK file to the controller after the automatic processing and accurate

calibration;

Note: under normal circumstances on the white paper burned black traces need

11%-13% power, according to the actual situation. Recalibration of the sensor

according to the color of the burn marks to accurately detect the relative position.