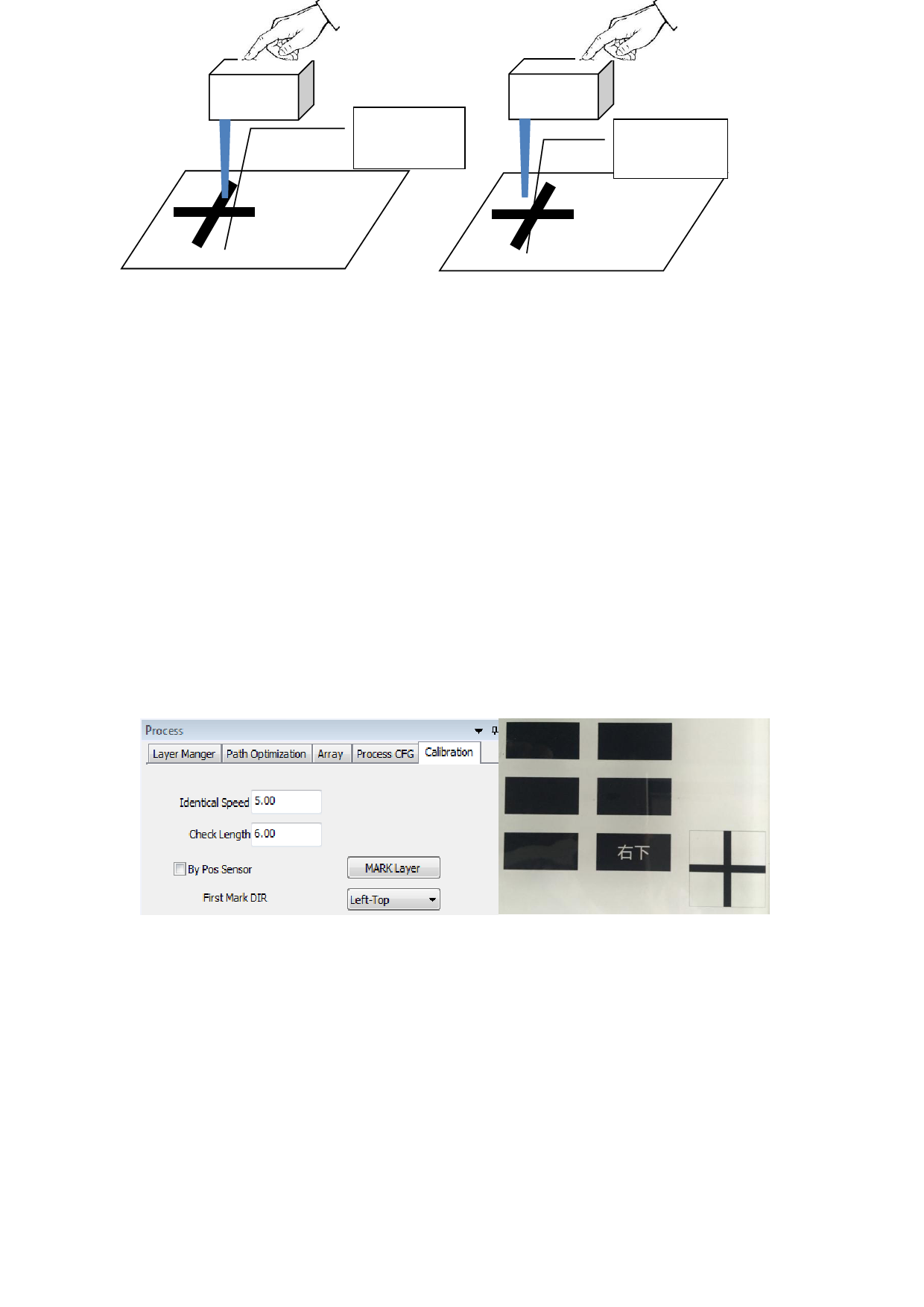

ON

sensor

Alignment

MARK

OFF

sensor

Alignment

background

MARK printing requirement

Requires 4 MARK points to be printed in the need to cut the graphics in the four

corners, the width of the MARK point should be at least 5mm, the length should be at

least 40mm.

The wider the line width of the MARK point , the faster the speed of the scan

location can be, and the easier it is to locate it; usually the speed is set to less than or

equal to 10 mm/s.

The longer the length of the MARK point, it is also possible to accurately locate

the workpiece when the tilt angle is larger. Usually the workpiece angle is less than 15

degrees, the parameter settings are shown below.

There are obvious differences between the MARK color and background color,

attention must have the background color (not when acrylic material printing is

transparent), as shown below.

In order to facilitate the use of the MARK point each time the design of the

processing are white and black, so it does not need to be processed before each re

color calibration of the sensor.

The requirement of MARK point when drawing outline

1:MARK must be a single element hollow profile and closed, if it is composed of

the line, you need to select the composition of all segments of MARK point, click the

right mouse button, select "merge Adjacent lines", the merger is a primitive.

2:MARK points must be four hollow cross, cross center must be able to complete

the formation of a rectangle, that requires the center of the 4 cross in both horizontal

and vertical alignment of the two directions. As shown in the red rectangle box: