Function

5/14/2018 Code

Name

F1.19 Upper torque limit setting

Setting Range

Default

Value

0.0~200.0%(inverter rated current) 150.0%

The setting 100.0% is corresponding to the rated output current.

The function code below(F1.20~F1.24) are valid to V/F control F( 0.00=1 ), but invalid to vector

control.

Function

Code

Name

F1.20 V/F curve setting

Setting Range

0:Linear V/F curve

1:square torque V/F curve

Default

Value

0

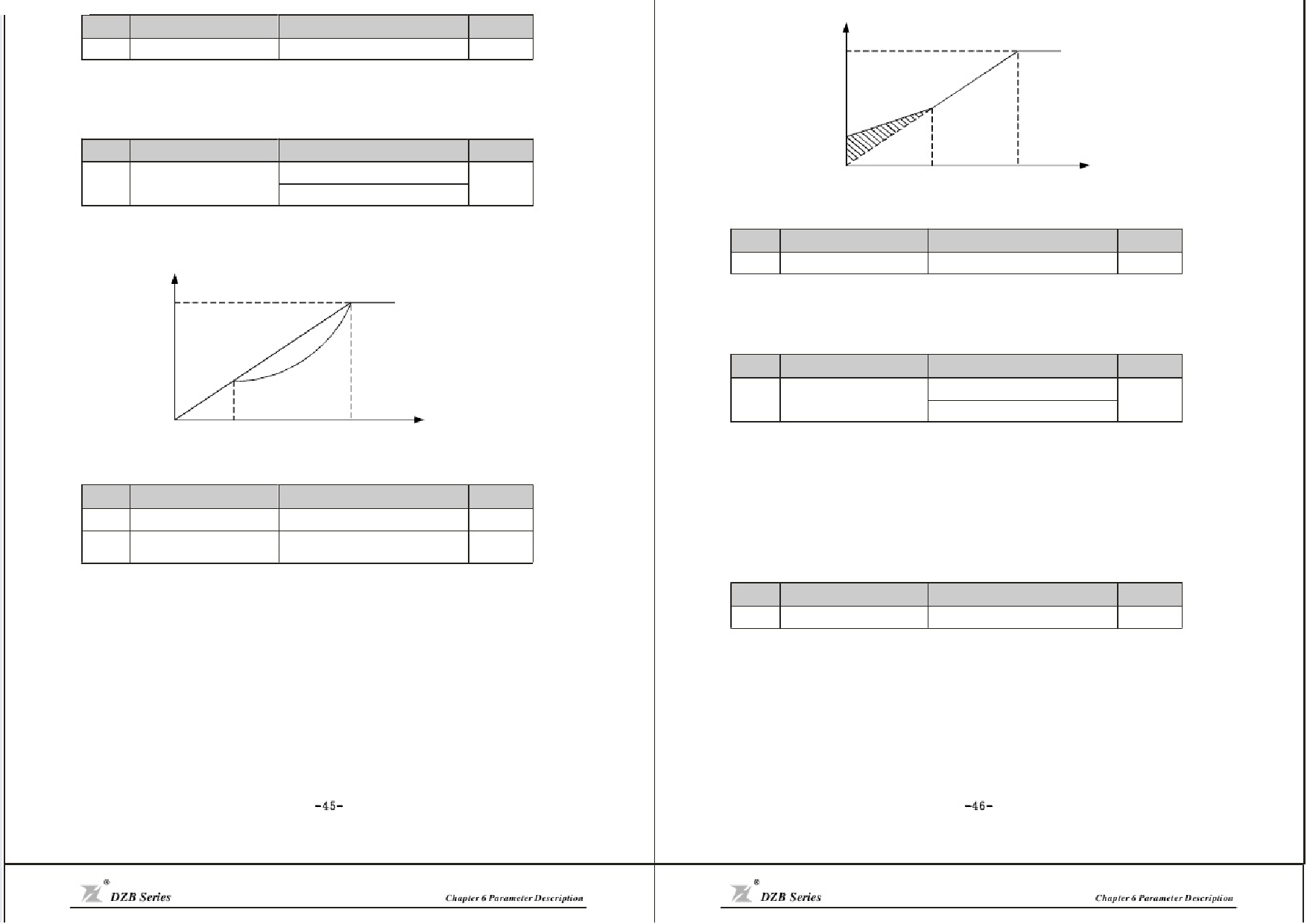

0: Linear V/F curve. It is applicable to constant torque load.

1: 2.0 exponential V/Fc urve. It is applicable to variable torque load, such as blower, pump etc.

Output Voltage (V)

V b

Linear V/F curve

2.0 exponential

V/F curve

Fuling Inve r te r Use r Ma nua l - slide pdf.c om

Output Voltage (V)

V

b

V

boost

f

cut-off

fOb utput Frequency f

Fig. 6-7 Manual torque boost diagram

Function

Code

Name

Setting Range

F1.23 V/F slip compensation limit 0.0~200.0%

Default

Value

100%

Setting this parameter can compens ate the motor speed change produced because of undertaking

loading while on V/F control, to increase the ri gidity of motor mechanical performance. This value

should be set as the motor rated slip frequenc y.

Function

Code

Name

F1.24

Energy Conservation

Selection

Setting Range

0:No Operation

1:EnergyConservation

Default

Value

0

1/3 fb

f b

Output Frequency f

Fig. 6-6 V/F curvediagram

Function

Code

Name

F1.21 Torque boost

F1.22 Torque boost cut-off

Setting Range

0.0%:(auto) 0.1%~30.0%

0.0%~50.0% (relative to motor

rated frequency)

Default

Value

0

20.0%

Torque Boost is mainly applied to less than cut-off frequency (F1.22). The V/F curve after boost is

shown in following figure. Torque booth can improve the low frequency torque performance of V/F control.

Based on the load, a torque should be chosen properly. For heavy load, increase the tor que boost, but

the torque boost should not be set too big, which will resul t in the motor operating at overexcitation and

that it could be overheated, and also the inverter output current is big, reducing efficiency.

When the torque boost is set as 0.0%, the inverter i s at automatic torque boost.

Torque boost cut-off frequency: below this frequency, torque boost is valid, and above this frequency

setting, torque boost is invalid.

When the motor is running in no-load or lower-load during,the inverter can adjust output voltage

by automatically current kf the load。

Note:This function is especially valid for variable torque load (such as fan and pump).

F2 Input and Output Terminal Function Parameters

Function

Code

Name

F2.00 On-off signal filter times

1~10

Setting Range

Default

Value

5

It sets up S1-S6, VI and CI terminals sample filtering time. In big interference situation, this parameter

should be increased in order to prevent mal operation.

-45-

http://slide pdf.c om/re a de r/full/fuling-inve r te r-use r-ma nua l

-46-

26/54