The centering and adjustment of laser

beam

The centering of laser beam

The cutting quality mainly depends on whether the optical lens is in the center or not. If the optical

lens is not in the center, the laser beam will reach to the inside parts of the cutting head thus the inside

parts can be easily out of shape because of high temperature. Thus, whenever the cutting quality is

getting worse, please try to adjust the position of optical lens or the nozzle tips and try again.

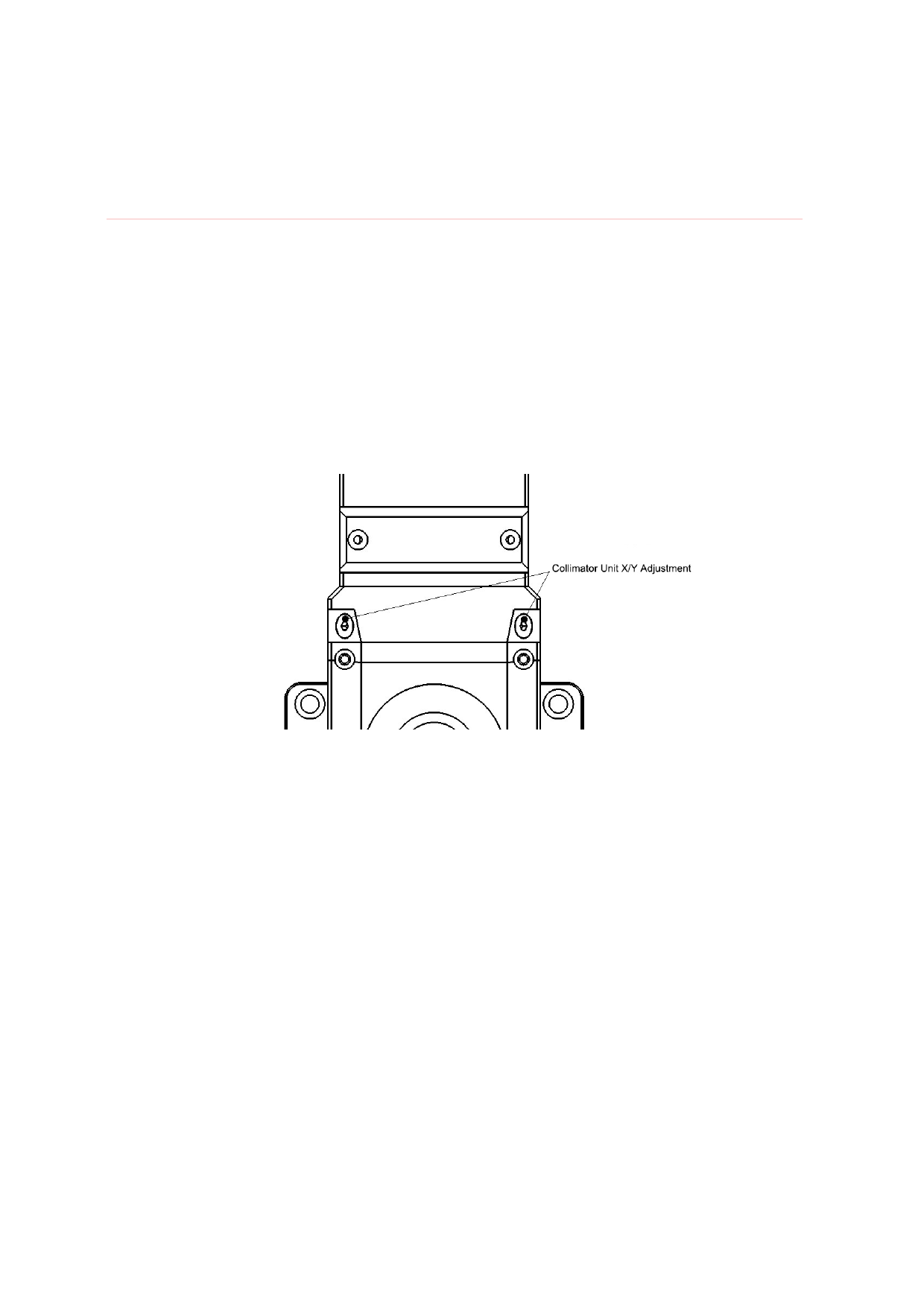

Figure 8. The centering of laser beam of A200M fiber laser cutting head.

The centering of A200M fiber laser cutting head can be done by adjusting the X-Y direction of

collimate lens. Collimator Unit X/Y Adjustment showed as Figure 8. The adjustment can be done by

using hexagonal screw driver until the laser beam is in the center of nozzle tips. Please make sure the

laser beam is in the center of the nozzle tips before start cutting. Normally you could try to use this

way to check if the laser beam is in the center of nozzle tips or not:

(1) Take one piece of scotch tape and then horizontally stick on the bottom of nozzle tips;

(2) Open the red light inside the laser source and then take out the scotch tape you stick on the

nozzle tips to check if the red right is in the middle of the nozzle tip’s center hole. If not, please adjust

the X-Y direction of collimate lens and repeat the first two steps until it does;

12 / 20