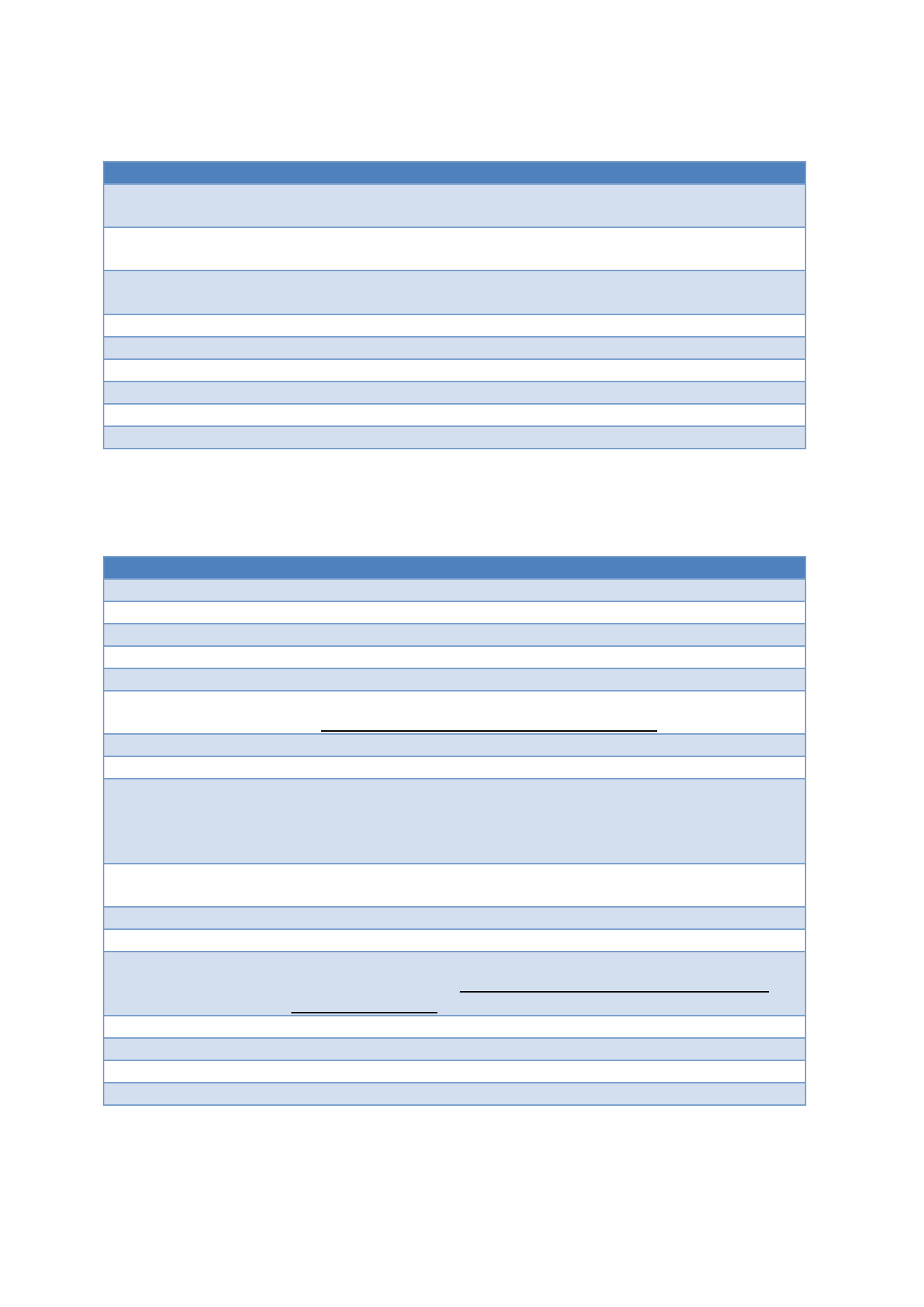

F1 Common: Common Settings for Plasma and Flame Cutting

Setting

Max Cutting Speed

Manual Move Speed

G00 Move Speed

Demo/Back Speed

Marker Speed

Kerf Value

Corner Speed

Demo Run Speed

Cutting Type

Suggest Value

Setup maximum cutting speed depends on material, not suggest higher

than 4000mm/min, normally 300 – 2000mm/min

6000 mm/min, 6meter per minute is the maximum speed machine

designed for with the stepper motors installed

4000 mm/min, the torch moving speed from one path to another within

a cutting process. Set lower than maximum speed avoids loosing steps.

2000 mm/min, the speed used for move backwards

0, no use

Normally 0.3 to 1mm, half of the value of the width of the cutting gap

95% of normal speed suggested, can be lower if not cutting through

4000 mm/min, the speed used for demonstration cutting process

Flame, Plasma or Demo, depends on your requirement

F3 Plasma: Plasma Cutting Settings

# those values have been override by the Easy Panel

Setting

Delay Before Arc

Pierce Time #

Torch Up Time

Arcing Check Time

Position Check Time #

Position Up Time #

Speed to Lock THC

Distance to Lock THC

Lose Arc Delay

Time to Lock THC

Before M08

Watch Arc Enable

Use Cylinder THC

Arc-Voltage #

Over-Arc Protection #

Sensitive #

Step #

Position Time #

Suggest Value

0.3 – 0.4s, time delay from torch positioned to arc, to avoid vibration

0.3 – 0.8s or more, depends on the plate thickness

1 – 2s, when finish one cut, lift time before move to next one

15s

10s

0.3 – 0.6s, after torch touched plate, lift time before positioned and arc.

The optimal distance for piercing is between 2-3 mm.

95.00% mm/min, disable THC if speed lower than this setting

5mm, when part of cutting path less than this distance, disable THC

0s, delay for machine gives warning when arc broke. Need to setup

delay if you cut mesh or grill, or with lead in/out -- try 0.5s.

For Hypertherm unit, try 1.5s since the signal from Hypertherm

Powermax unit generally have delays.

0s

Yes, enable Arc-Voltage checking. Set to No to disable THC

No

130.00V

Change the value to get optimal distance of cutting between plate to

nozzle about 2-3 mm.

30.00V

40.00%

1.00V

6.00S

2