- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- MetalWise-CNC-Plasma-Cutting-Machine

- FastCAM

- Demo

- TIB.pdf

- Page 1 of 2

Tradesman in a Box™

WORKSHOP LAYOUT FOR HAND HELD OXY

Ideal for Fabricators without CNC Machinery

HIGHLIGHTS:

THE FAST WAY TO PRODUCE PATTERNS READY FOR MANUAL CUTTING

• SPECIFICALLY DESIGNED FOR

THICK PLATE!

• INCLUDES COMMON,

COMPLEX AND HEAVY

CONSTRUCTION SHAPES

• INSTANT FLAT PATTERNS

• FULL MANUFACTURING AND

WELD DETAILS

• AUTOMATIC & EASY!

• MULTI-LANGUAGE SUPPORT

• MICROSOFT WINDOWS

Nuts and Bolts:

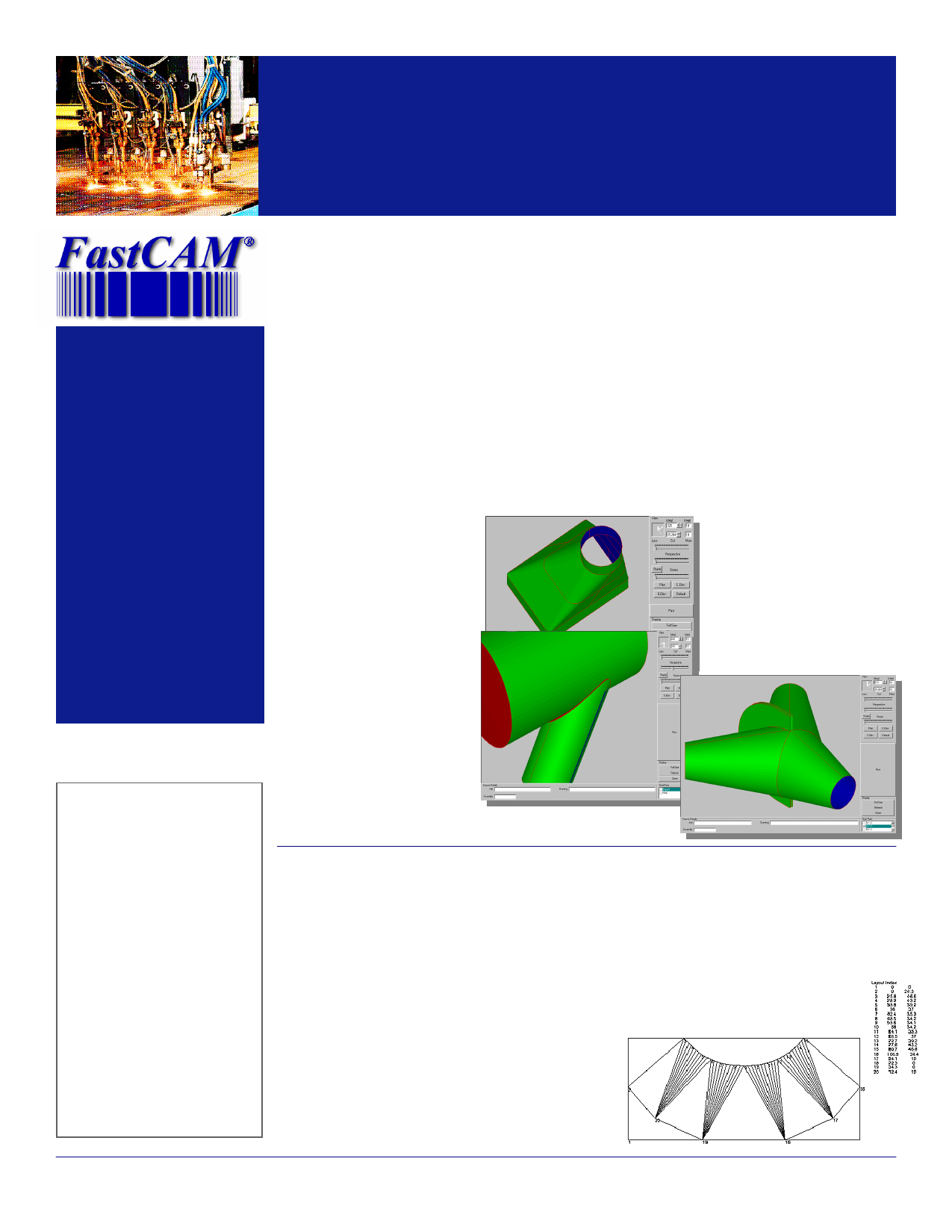

Dynamic Display changes shape

as data is entered

Full 3D Viewing inc stereoscopic,

Plan, Elevation & Isometric

‘Cutaway’ feature lets you see

inside the development

Calculates Bend Lines, Forming

Angle, Longitudinal Seam Off-

sets and more

Every component of a construc-

tion can be viewed independently

Includes 2D Drawing System

Loft patterns directly from

printout

Tradesman in a Box™ is a

complete affordable solution

for the workshop that does

not have CNC machinery.

Take out the guesswork and

eliminate the need for

calculations!

Shapes can be completed in

a fraction of the time

manually lofted patterns

would allow and importantly,

they are fabricated “right first

time”.

Simply model the item in 3D

(you see the shape appear as

data is entered) and produce

output for manual lofting.

The system is sophisticated

but uses familiar shop floor

terminology making it

very easy to learn with ‘user

tips’ and a comprehensive

online help system.

With shapes covering most

thick development needs:

Common

Shapes

Complex

multi components

Common: Rectangle to Round,

Elbow, Pipe Branch, Lobster,

Multi Segment Cone, Oblique

Cone, Cone Bifircate, Plate

Branches.

Power Transmission: Chain

Sprocket, Universal Sprocket,

Rack and Pinion, Involute Gears.

Heavy or Complex

Transitions: Tapered & Trans-

forming Lobsterback Bends,

Offset & Mitred Transformers,

Conical Branches, Conical &

Tubular Runs, Simple & Complex

Birfircations.

Full welding

preparation details

Tradesman in a Box™ is for medium to heavy plate manufacturing

where the main joining technology is welding.

CO-ORDINATES FOR LOFTING OR USE WITH AN OPTICAL MACHINE

The system allows for multi

strake, variable thickness

construction with internal,

mean or outside data entry.

Full fabrication Dev. includes

Welds, Full/Partial Penetra-

tions, Fillet, Butt/Groove.

Highly accurate components

offer a marked improvement

in weld quality and

consistency resulting in better

fitup.

• Green Allowances

• Forming Angle

• Back to Back

“Stitch” Cutting

• Marking of bend

lines

• Mass of all Parts

• Assembly List

• Longitudinal

Seam Offsets

The detailed printout makes it very simple

to loft and cutout by hand, or printout at a

1:1 scale and use with an Optical

Machine.