“CUT SMARTER, QUOTE FASTER” SOFTWARE SOLUTIONS FOR METAL PROCESSING SINCE 1976

FastSHAPES® offers the

most dramatic savings

when working with :

• Large fabricated shapes

which require a lot of

additional fabrication

information (often multi-

segmented).

• Complex equation based

developments such as

gears.

• Predictable multi-

component develop-

ments.

DESIGNED FOR REALWORLD APPLICATIONS

FastSHAPES® was

specifically designed to be

able to handle medium and

thick plate. The program

has been used in real world

production solutions since

1989.

Pipe branches, transitions,

heavy ducting, anything for

Hydro-electric, mining infra-

structure or general heavy

fabrication are handled

superbly.

FastSHAPES® has proven to

offer substantial time &

material savings ranging from

mining buckets to wind-farm

towers.

FastSHAPES® has also been

used in the development of

Naval Frigates and nuclear

and conventional submarines.

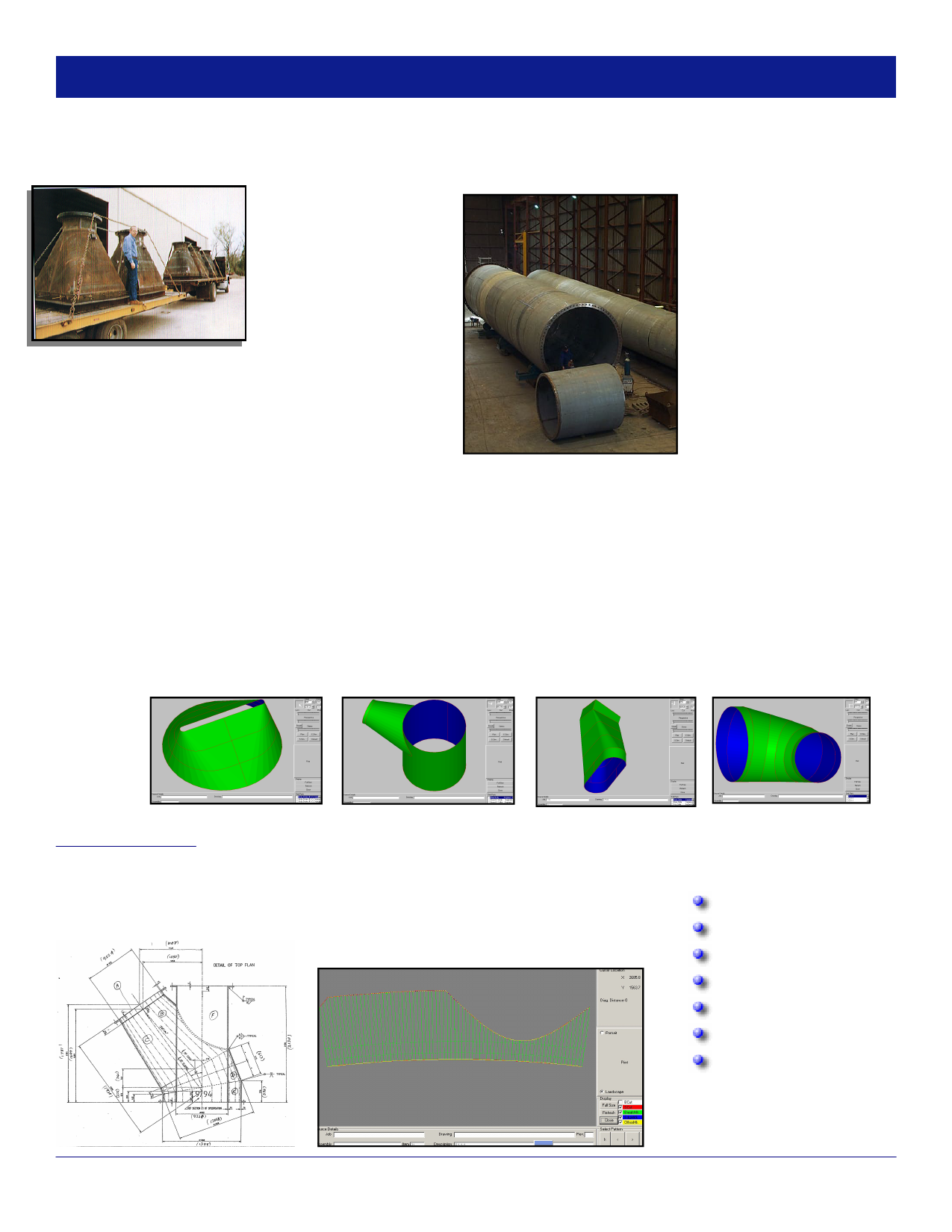

These large conical structures

are used to support Turbines at

a Wind Farm.

DEVELOP A FULL RANGE OF ‘PRODUCTION READY’ FLAT PATTERNS

Common Blowpipe

Rectangle to Round, Elbow,

Pipe Branch, Lobster, Multi

Segment Cone, Oblique

Cone, Cone Bifircate, Plate

Branches.

Power Transmission

Heavy/Complex Transitions

Chain Sprocket, Universal Tapered & Transforming Lobster-

Sprocket, Rack and Pinion, back Bends, Offset & Mitred

Involute Gears.

Transformers, Conical Branches,

Conical & Tubular Runs, Simple

& Complex Birfircations.

Note: With over 20 shapes in the library, FastSHAPES® covers most of the shape development needs of fabricators and service centers.

Makes easy work

of even complex

fabrication jobs.

FULL MANUFACTURING DETAILS TO INTERNATIONAL STANDARDS

FastSHAPES® allows for multi

strake, variable thickness

construction with internal,

mean or outside data entry.

Full fabrication development

includes Welds, Full/

Partial Penetrations, Fillet,

Butt/Groove.

Green Allowances

Forming Angle

Back to Back “Stitch” Cutting

Marking of bend lines

Mass of all Parts

Assembly List

Longitudinal Seam Offsets