FastSHAPES® System

INSTANT PLATE DEVELOPMENTS

Ideal for Boilermakers, Draftsmen & Engineers

HIGHLIGHTS:

THE FAST WAY TO PRODUCE PATTERNS READY FOR CUTTING

• SPECIFICALLY DESIGNED FOR

THICK PLATE!

• INCLUDES COMMON, COMPLEX

AND HEAVY CONSTRUCTION

SHAPES

• PRODUCTION-READY

FLAT PATTERNS

• FULL MANUFACTURING AND

WELD DETAILS

• AUTOMATIC & EASY!

• MULTI-LANGUAGE SUPPORT

• MICROSOFT WINDOWS

Nuts and Bolts:

Dynamic Display changes shape

as data is entered

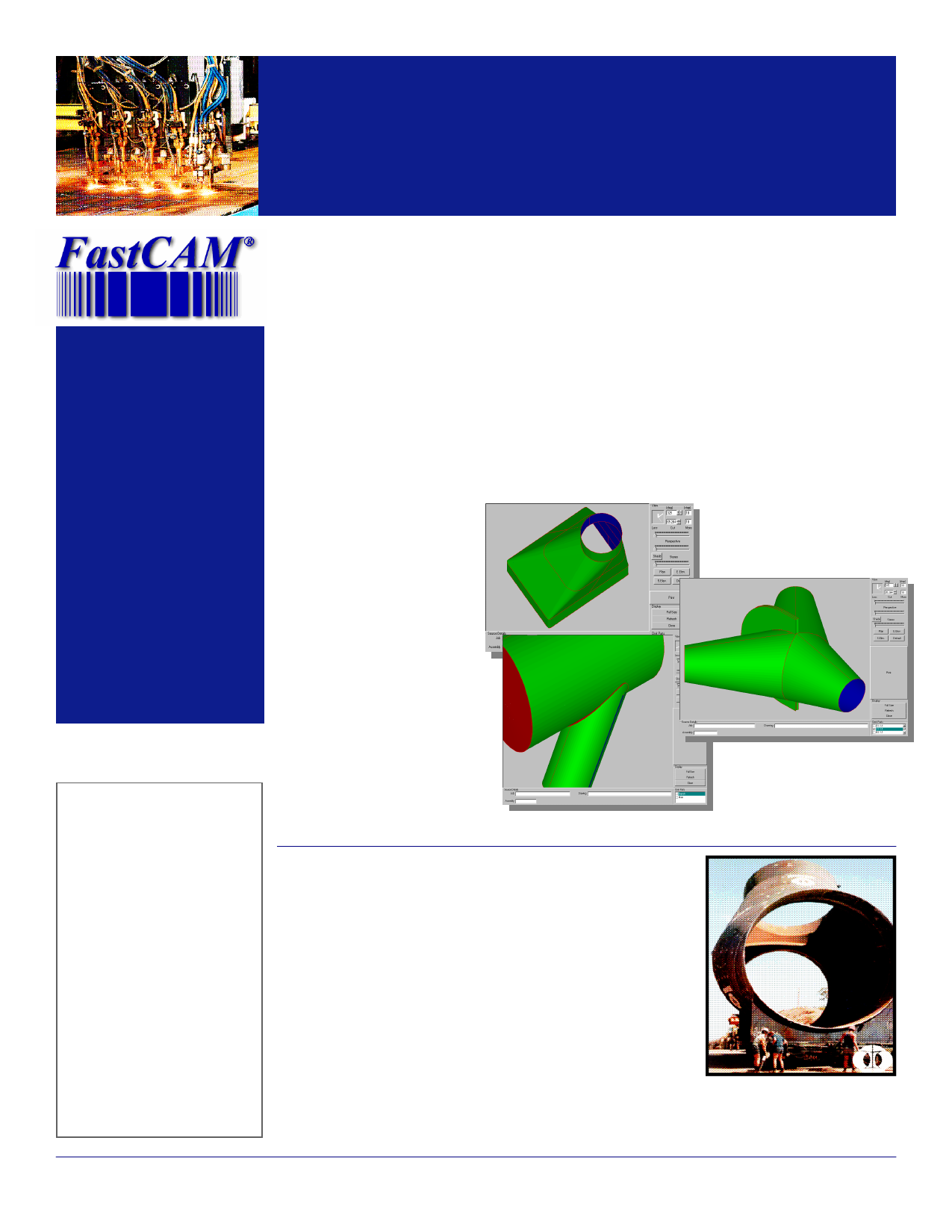

Full 3D Viewing inc stereoscopic,

Plan, Elevation & Isometric

‘Cutaway’ feature lets you see

inside the development

Calculates Bend Lines, Forming

Angle, Longitudinal Seam Off-

sets and more

Every component of a construc-

tion can be viewed independently

Plotted layouts

2D & 3D DXF CAD output of

shapes and flat pattern

The FastSHAPES® System

contains a full suite of

programs designed to

automatically create flat

pattern developments for

both common & complex

fabricated items.

Shapes can be completed in

a fraction of the time

manually lofted patterns

would allow and importantly,

they are fabricated “right first

time”.

Simply model the item in 3D

(you see the shape appear as

data is entered) and produce

output for cutting or manual

lofting.

FastSHAPES® automatically

produces meaningful data for

the forming and joining of

parts when appropriate.

The system is sophisticated

but uses familiar shop floor

Common

Shapes

Full welding

preparation details

easy to learn with ‘user tips’

and a comprehensive online

help system

With shapes covering most

thick development needs,

FastSHAPES® offers dramatic

benefits to any heavy

fabrication related business.

Complex

multi components

FastSHAPES® is for medium to heavy plate manufacturing where the main jointing technology is welding.

“RIGHT FIRST TIME”

Take out the guesswork and

eliminate the need for

Calculations!

This computer based system

can handle thousands more

computations which is

reflected in the capacity and

accuracy of the system.

Particularly when compared

to hand lofted pattern

developments.

FastSHAPES® produces clean

and precise geometry that you

can export as a DXF (CAD) file

or into your CAM system for

editing and/or nesting if

desired.

Highly accurate components

offer a marked improvement

in weld quality and

consistency resulting in better

fitup.

FastSHAPES® completed this complex

hydro-electric component in only minutes

ready for burning, with all forming details

and even plate edge preparation (PEP).