FastCAM® NC System

Feature Comparison Chart

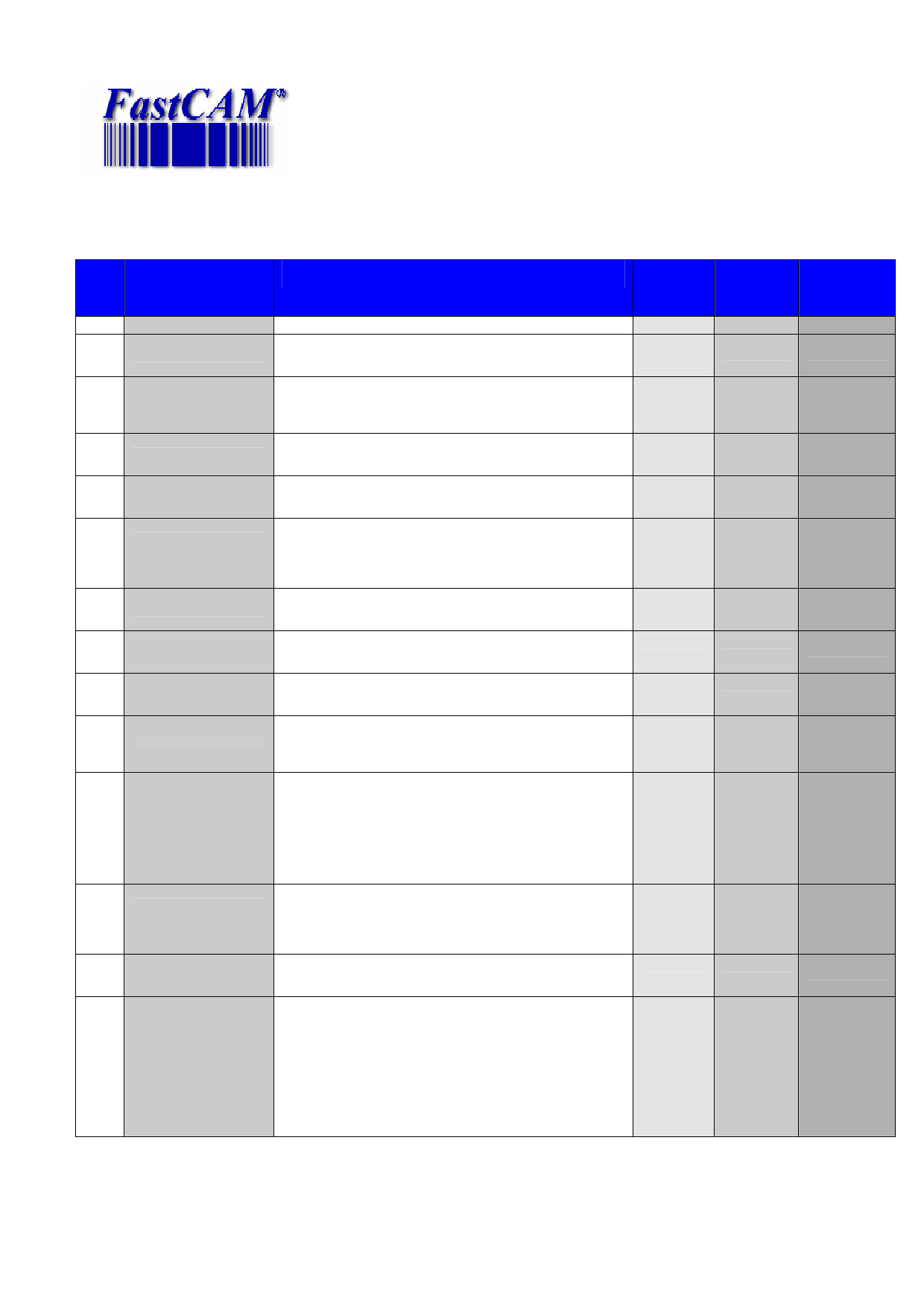

Item

Features

15

Part “Bump”

Placement

16

Interactive Part

Placement

17

Plate Trim

18

Auto Arraying of

Individual Parts

19

Remnant Nesting

20 Bulk Import of DXF &

IGES files

21

Multi-Plate Nesting

22

Bridging of Parts

Overcut

23 FastPATH Automatic

Tool Pathing

24

Automatic Part

Extraction

25

Automatic Cut List

26

Automatic Nesting

27

FastCAM Linking

OPTION

** THIS FEATURE IS

AN EXTRA COST

Descriptions

Automatically moves parts to the preset distance.

FastCAM®

NC

Basic

FastCAM®

NC

Standard

FastCAM®

NC

Professional

Select, click and drag and drop parts to desired placement.

Flip, mirror on any axes, rotate, move, align while FastCAM

automatically sets kerf and proper cutting direction.

Automatic plate cutoff after nesting is complete with

optional stored “off-cut” for later retrieval.

Creates Arrays or patterns of similar parts within nesting.

Ideal for cutting multiple same parts within nests.

Nesting into previously cut plate not just FastCAM

but virtually any source, any size, shape or weight.

Can be optionally linked to FastCAM’s FastTRACK

system for full inventory tracking of remnant stock.

Multiple file import/export.

Automatically nests parts across multiple plate stock

including remnant nesting.

Cut path “overcuts” bridges to remove material completely

resulting in a smoother better quality finish at the bridge.

Totally automatic creation of cutting path including lead ins,

lead outs, for both internal and external requirements,

determining cutting direction and auto setting of kerf.

A Single CAD drawing may consist of a series of assemblies,

sub assemblies and parts comprising a parts list.

As opposed to manually selecting these one by one

for further work, FastCAM can automatically search

for related subassembly and parts by profiling which can

be singled out and extracted, separated and exploded for

detailed analysis, modification or complete redrawing!

FstCAM will automatically create, a multiple list of parts

from the DXF file after exploding which are to be nested.

The list may be modified at will by adding or deleting parts

as desired.

Automatically places parts for cutting as economically

as possible on given sizes of selected material.

Worth noting is the FastLINK™ Program.

This program is not part of the Fast CAM® System but is a

separate option. It provides required

capability for bi-directional NC file transfer between a

Windows based personal computer and one or more

controllers via serial communication links.

Most major name controllers are compatible.

A sever version is available for some controllers.

FastLINK is compatible with all FastCAM® Systems.

OPTION OPTION OPTION

FCSYSCOMP001-05