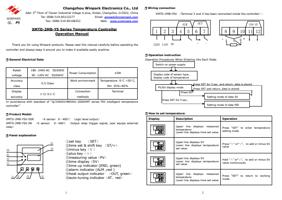

How to set delay time:

Display

Description

PV

Upper line displays measured temperature

SV

Lower line displays time set value

Operation

Press “< ” key to enter time

setting mode

PV

Upper line displays TV

Press “∧” or“∧”, to add or minus

SV

Lower line displays time set value

TV value

PV

Upper line displays TV

Hold “∧” or“∧”, to add or minus

SV

Lower line displays time set value

SV value continuously

PV

Upper line displays measured temperature Press “SET” to return to working

SV

Lower line displays time set value

mode.

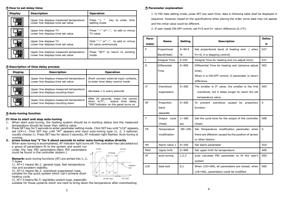

Description of time delay process

Display

Description

Operation

PV

Upper line displays measured temperature Short connect external input contacts,

SV

Lower line displays time set value

to enter time delay control mode

PV

SV

Upper line displays measured temperature

Lower line displays counting down

decrease 1 in every seconds

PV

SV

Upper line displays measured temperature

Lower line displays counting down

After 20 seconds, lower line counts

down to“0”, output time delay,

“END”indicator on the panel turns on

Auto-tuning function

How to start and stop auto-tuning

1. When start auto-tuning, the heating system should be in working status and the measured

temperature should be lower than setting value.

2. Press SET key for 5 seconds to enter parameter setting mode. Click SET key until “LCK” appears,

set LCK=1. Click SET key until “AT” appears and input auto-tuning type (1, 2, 3 optional,

usually choose 1). Press SET key for about 5 seconds, AT indicator light flashes. Auto-tuning is

running.

3. press minus key“Ⅴ”for 5 about seconds to enter auto-tuning status directly

When auto-tuning is accomplished, AT indicator light turns off. The controller has calculated out

a group of parameters fit to the system and would run

under the new PID parameters.(New PID parameters

could be found in the controller system.)

Remark: auto-tuning functions (AT) are sorted into 1, 2,

3 types

1). AT=1 means No.1: general type, fast temperature

rise and excellent stability.

2). AT=2 means No.2: overshoot suppression type,

suitable for the quick system which can’t achieve short

heating cycle.

3). AT=3 means No.3: lag/delay system type, especially

suitable for those systems which are hard to bring down the temperature after overshooting

3

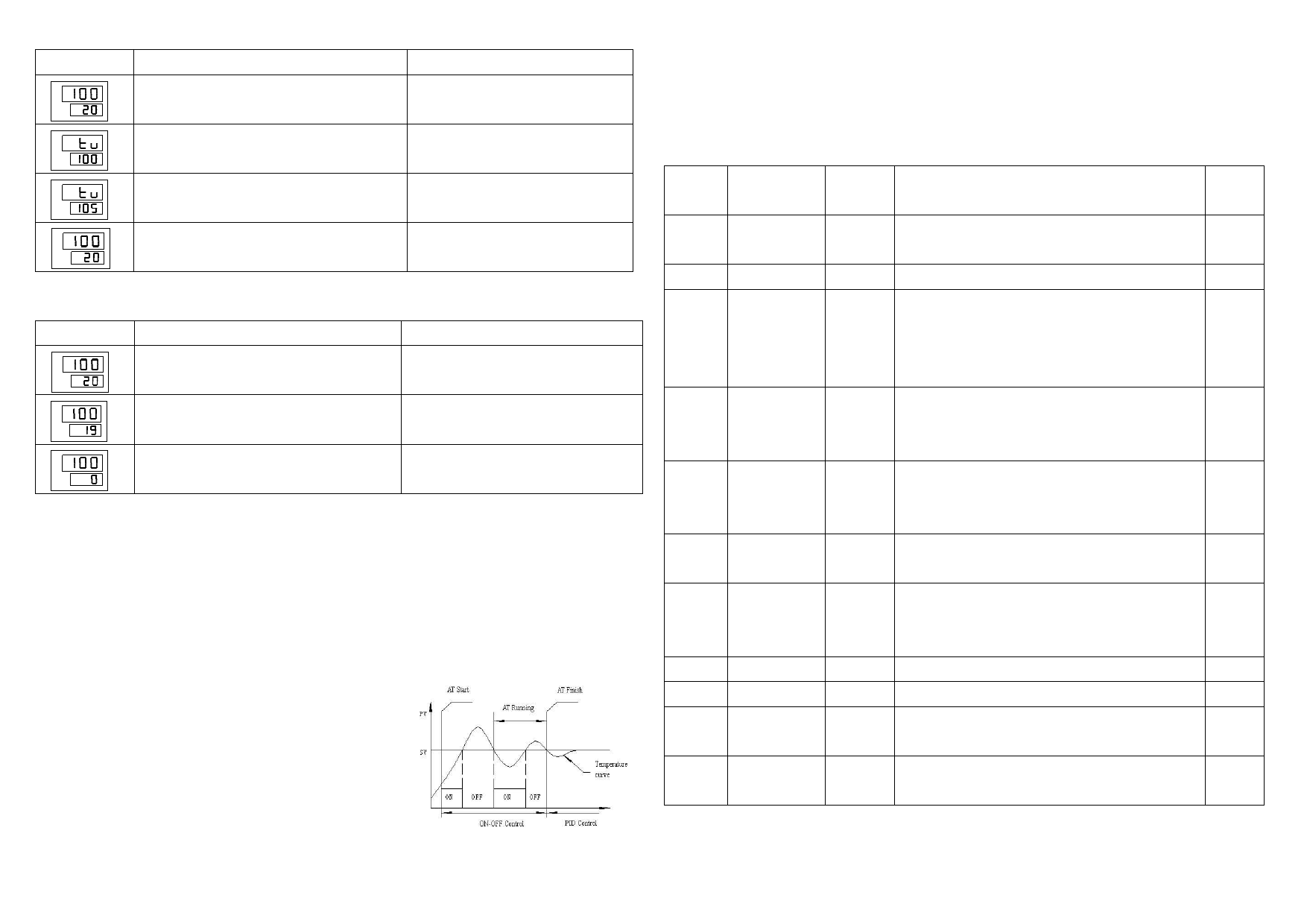

Parameter explanation

1. In PID data setting mode, press SET key each time; data in following table shall be displayed in

sequence. However, based on the specifications when placing the order, some data may not appear

and the initial value could be different.

2. If user needs ON-OFF control, set P=0 and D= return difference (0.1°C)

Para-

meter

Name

Setting

Description

Defau

lt

P

Proportional

0~99.9 Set proportional band of heating end ( when 027

Band(Heat)

%

Pv=0, it is stepping control)

I

Integral Time 0-250

Integral Time for heating end (re-adjust time)

031

D

Differential

0~999

Differential Time for heating end (advance adjust 005

Time

time).

When it is ON-OFF control, D parameter is return

difference

IT

Overshoot

0~200

The smaller is IT value, the smaller is the first 005

suppression

overshoot, but it takes longer to reach the set

temperature value.

SP

Proportion

0~200

To prevent overshoot caused by proportion 0

band

function.

separate

T

Output cycle 1~180

Set the cycle time for the output of the controller 008

(Heat)

sec

(heat)

TR

Temperature -99~100 Set Temperature modification parameter when 0

modification

there are affection caused by the position of sensor

or other factors

AH

Alarm value 1 0~100

Set alarm parameter

010

RAG

Upper limit

0~999

Set upper limit for temperature

400

AT

auto-tuning 1,2,3

auto calculate PID parameter to fit the user’s 000

system

LCK

data lock

0,1

When LCK=000, all parameters are locked; when 000

LCK=001, parameters could be modified.

4