Page 3 of 5

White Paper

Measurement Illumination Condition M1

Measurement illumination condition M1 was defined to reduce variations in measurement results between instruments due to

fluorescence, either by optical brighteners in paper or fluorescence of the imaging colorants or proofing colorants. M1 (Part One)

specifies that the spectral power distribution of the light source used to measure the specimen should match CIE Illuminant D50. M1

also defines a second, (Part Two) method for achieving M1 compliance that is only valid for measuring optically brightened papers but

not for measuring inks or toners that fluoresce. This is due to the historical complexity of delivering a true D50 illumination in handheld

instruments. This second definition only requires that a compensation method is used with a controlled adjustment of the amount of UV

component (spectral region below 400 nm) used to measure. This is to provide correlation to the D50 illumination conditions as defined

in ISO 3664:2009 viewing standard. This second method must be tied to a viewing condition compliant to ISO 3664:2009, so caution

in using it must be exercised, and testing for agreement is advised.

Measurement Illumination Condition M2

For the first time, an ISO standard defines what UV exclusion (variously known as UV-cut, No UV, or UV-filtered) should be in a

measurement tool. M2 also provides a test to ensure compliance to the standard. Instrument manufacturers now have a defined way

to provide agreement when customers require an instrument that does not contain UV. We will be able to measure papers containing

optical brightening agents and communicate color data with greater precision and consistency. X-Rite, as part of its XRGA efforts, has

made sure that all new UV-cut products meet this definition.

Measurement Illumination Condition M3

M3 defines the effect of polarization. In essence, M3 requires the UV-restricted properties of M2 and adds a definition of polarization.

Polarization is used in certain measuring instruments to remove or minimize reflections. Polarization is usually accomplished by

choosing a polarization function or adding an optional manufacturer-specific polarizing filter. X-Rite, as part of its XRGA efforts (see

below), has insured that its instruments offering M3 mode (polarization filter) provide a UV level that is compliant with the new standard.

Applications and use of M0, M1, M2, and M3

In theory, the cases where each of these measurement illumination conditions are used are relatively clear:

• M0 is for any use where neither substrate nor imaging colorants fluoresce.

• M1, part 1, is intended for use when either substrate or imaging colorants, or both may fluoresce.

• M1, part 2, is designed for use when a substrate may fluoresce, the fluorescing characteristic needs to be captured, and the user

is confident that the imaging colorants do not fluoresce. (When in doubt, consulting with the ink manufacturer is recommended.)

• M2 is for use when the paper fluoresces, but there is a desire to eliminate this effect from affecting the data.

• M3 is for special use cases where first surface reflections should be minimized, including the use of polarization to do so.

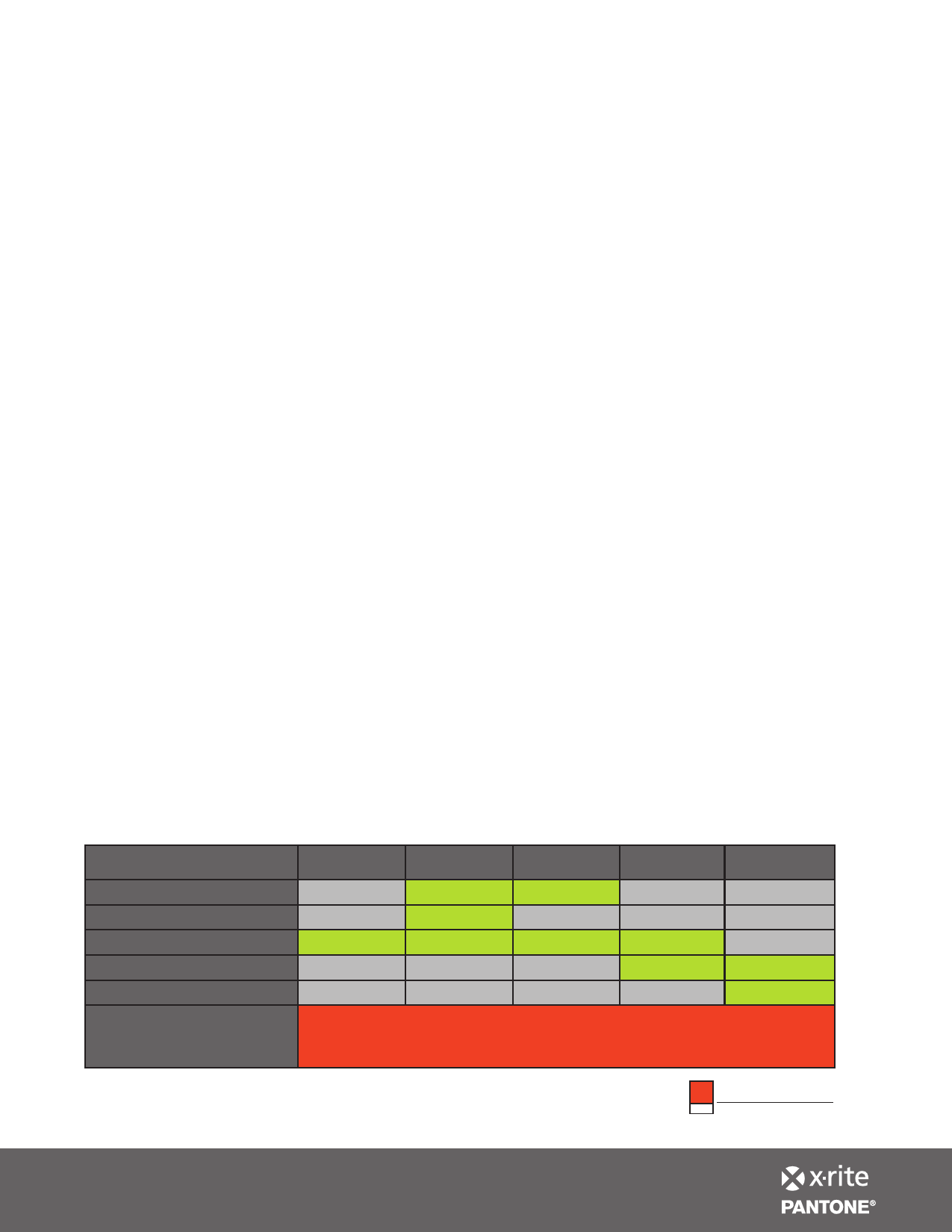

Measure effect of OBAs

Measure ink fluorescence

Measure non-OBA stock

Cut the effect of OBAs

Cut first surface reflections

Agree on M standard for use

in exchanging data prior to

measurement

M0

M1

M1

M2

M3

1

2

3

3

3

3

3

3

3

3

3

3

When using any M standard to exchange data, it is essential to agree on a

particular M standard before measuring data.

2012 COLOR OF THE YEAR

PANTONE® 17-1463

Tangerine Tango

X-Rite World Headquarters

Grand Rapids, Michigan USA • +1 800 248 9748 • +1 616 803 2100 • xrite.com

© 2011 X-Rite, Incorporated. All rights reserved. L7-510 (01/12)