EasyRoute Control Panel is based on Weihong NK105 CNC Integrated Machine OEM http://am.co.za/router/panel

上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

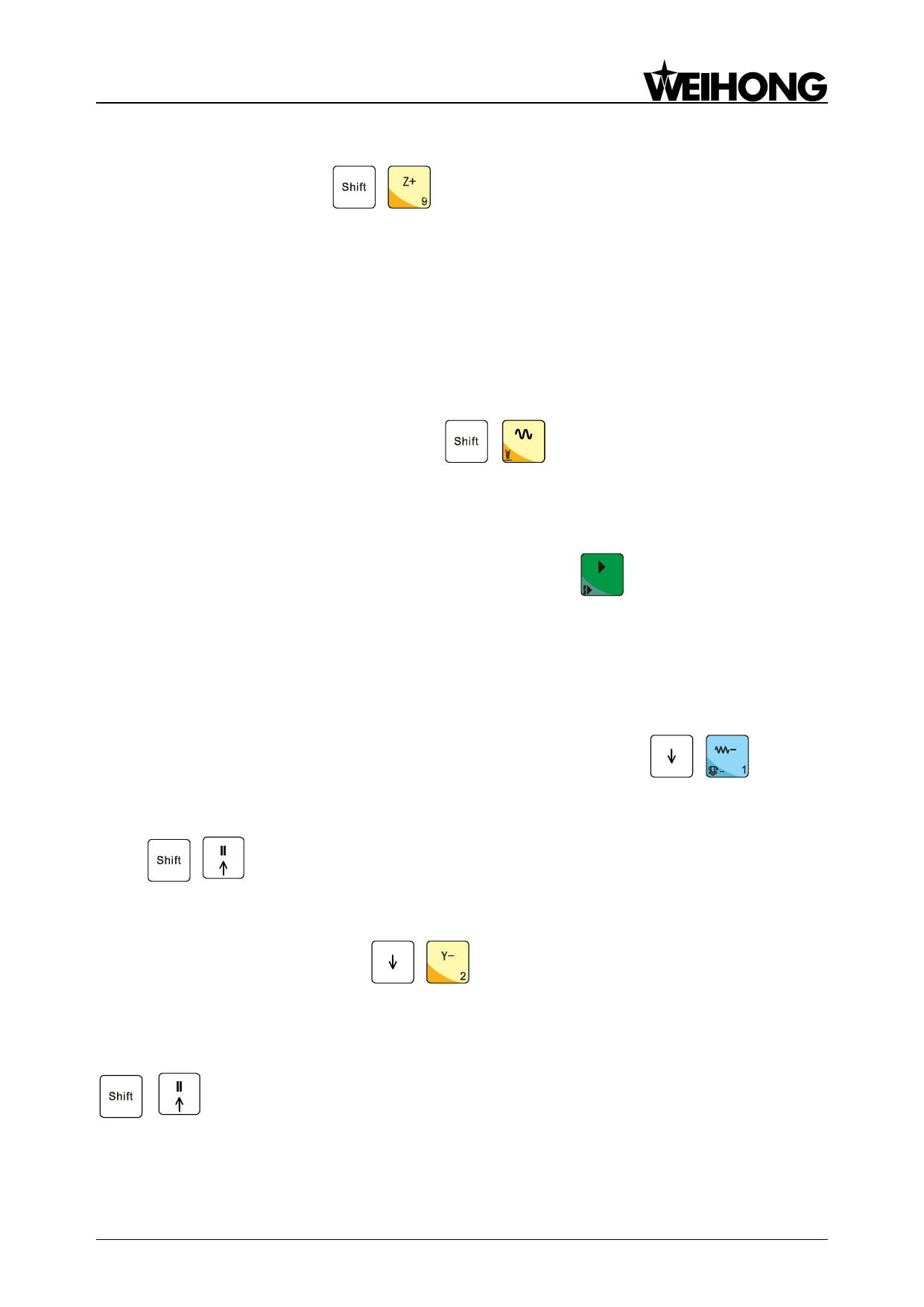

position of tool change (refer to parameter “CTUpPosition”) and open cylinder 2. Put the tool presetter

under the tool, and then press

+

. At this time, the Z axis will move downwards slowly

until touching the tool presetter, and then it will move up a little distance, “measure tool length

successfully” displayed. Pressing [OK] key will successfully set cylinder 2 by the system automatically

recording the current tool length into Z offset of current tool No.. Up to now, the length offsets of two

tools have been set successfully. The system will then call different offsets according to the

corresponding tool No. to make machining in the same plane.

The second step is to fix workpiece origin. Open a cylinder, put the tool presetter under the tool

(no matter which tool No.), and then press

+ 0 . At this time, the Z axis will move

downwards slowly until touching the tool presetter, and then it will move up to a point, “tool presetting

finished” prompted. Pressing [OK] key will set the point as workpiece origin of Z axis automatically.

The third step is to start machining automatically by pressing

. After machining finishes, it

is necessary to only perform the second step and the third step again without performing the first step

on condition that only a new workpiece is replaced with no change of the tool.

Operating Instructions with No Tool Presetter

The first step is to set the tool length. Under Jog mode, pressing

+

will open

cylinder 1. Manually adjust the Z axis to make its knifepoint touch the workpiece surface, and then

press

+

, “set tool length successfully” displayed. Pressing [OK] key will set cylinder 1

successfully by the system automatically recording the current tool length into Z offset of current tool

No.. Switch to cylinder 2, then press

+

to close cylinder 1 automatically, move up the Z

axis to upper position of tool change (refer to parameter “CTUpPosition”) and open cylinder 2.

Manually adjust the Z axis to make its knifepoint touch the workpiece surface, and then press

+

, “set tool length successfully” displayed. Pressing [OK] key will set cylinder 2

successfully by the system automatically recording the current tool length into Z offset of current tool

No.. Up to now, the length offsets of two tools have been set successfully. The system will then call

Specialized, Concentrated, Focused

57