EasyRoute Control Panel is based on Weihong NK105 CNC Integrated Machine OEM http://am.co.za/router/panel

上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

8.2.2. Confirm Workpiece Origin

The workpiece origin is the origin of workpiece coordinate system (X, Y, Z) in processing program.

The actual position of the workpiece origin should be confirmed before processing.

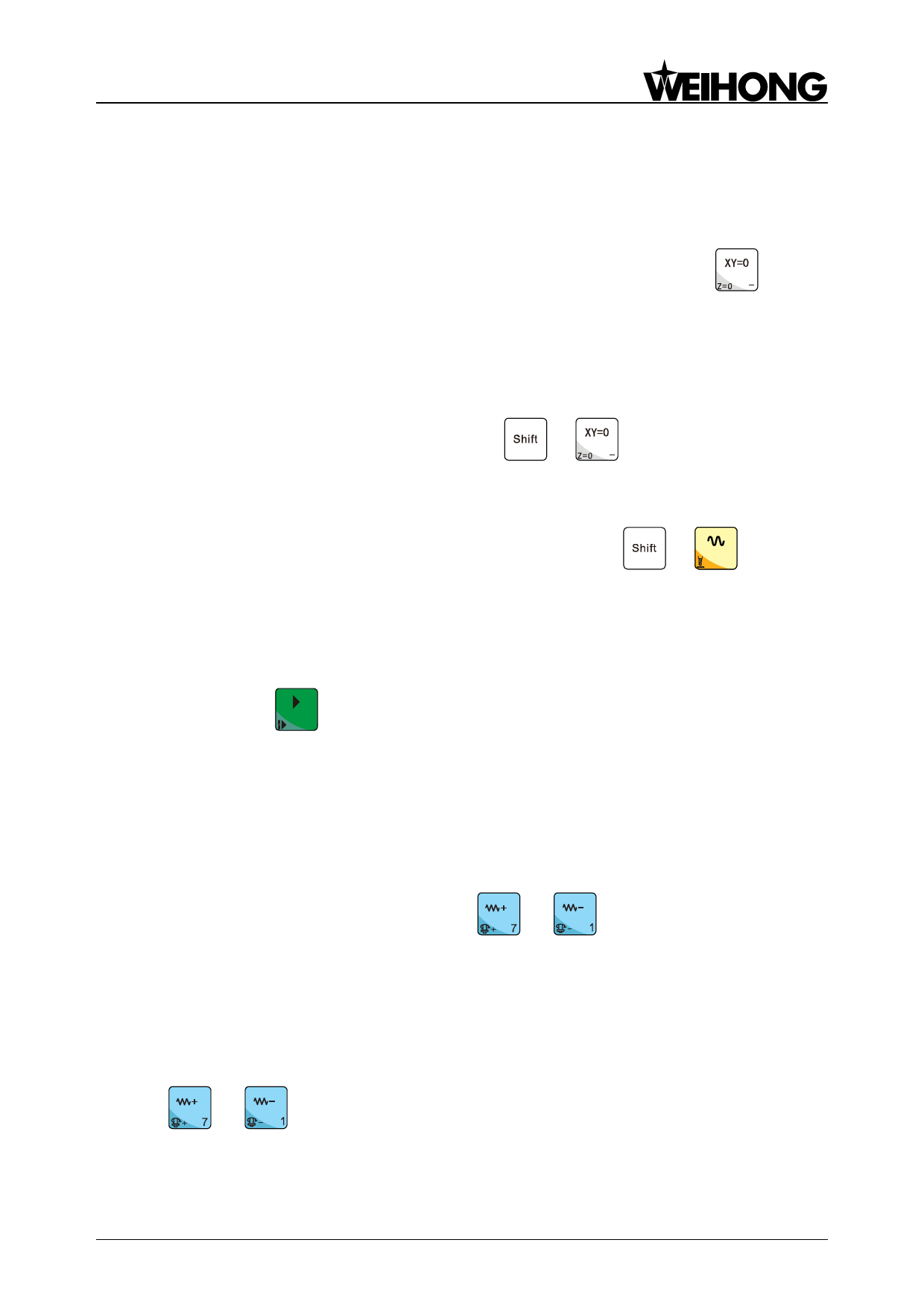

Manually move X and Y axes to the desired origin position, and then press

for zero

clearing. Thus, the workpiece origin along X and Y axes is confirmed.

For workpiece origin along Z axis, there are two ways to set it:

¾ Method one is the same as that to set workpiece origin along X and Y axes. Manually move Z

axis to the desired origin position. And then press

+

for zero clearing. Thus, the

workpiece origin along Z axis is set.

¾ Method two takes advantages of tool presetting function (press

+

presetting finishes, the coordinate of Z axis is the workpiece origin along Z axis.

8.2.3. Start Processing

0 ). After tool

Press the start key

to start automatic machining in the processing page.

Prompts like feedrate override and feed rate are scrolled on the screen during file processing.

8.3. Adjustment during Automatic Processing

Feedrate Override Adjustment

Feedrate override can be adjusted by pressing

or

during file processing. And the

feed rate changes with the feedrate override. The relation between actual feed rate and feedrate

override is as follows:

Actual feed rate = Feed rate × Feedrate override

The least unit of feedrate override is 0.1. Namely, override increases (decreases) 0.1 after each

press of

or

; at the same time, the screen displays the feedrate override increases

(decreases) 10 (%). The range of feedrate override is 0.0 ~ 1.2. In addition, the display of feed rate

Specialized, Concentrated, Focused

51