EasyRoute Control Panel is based on Weihong NK105 CNC Integrated Machine OEM http://am.co.za/router/panel

上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

Reference circle is the reference of

machine in processing circular workpiece.

Ref Cir. Speed

The max. speed of reference circle refers Min. speed of arc processing ~

to the max. allowable speed of machine in processing speed

processing this circle without strong

vibration.

G00 Feed 100%

Yes: not controlled by override

Whether G00 speed is controlled by

override switch

switch

No: controlled by override switch

After installation of machine tool, user can make the machine process an arc, in which vibration will

occur due to centrifugal force. The higher the speed is, the stronger the vibration will be. Gradually

increase the feed speed to see the state of vibration of machine tool until the max. circular speed is

achieved, i.e. the max. allowable speed of machine tool without strong vibration. This arc is regarded

as the reference circle, and its max. allowable speed is the max. speed of reference circle. Max.

centripetal acceleration “a” can be calculated in terms of the reference circle radius and its max

speed. The formula is as follows: V0 and R0 are the speed and radius of reference circle respectively,

while Vx and Rx are the speed and radius of the arc to be processed. After Rx is confirmed, when the

arc processing speed is larger than Vx calculated, the system will limit the arc processing speed

automatically to ensure it is within the debugging value, i.e. the vibration will not be stronger than that

during ex-factory debugging.

a = V02 = Vx2

R0 Rx

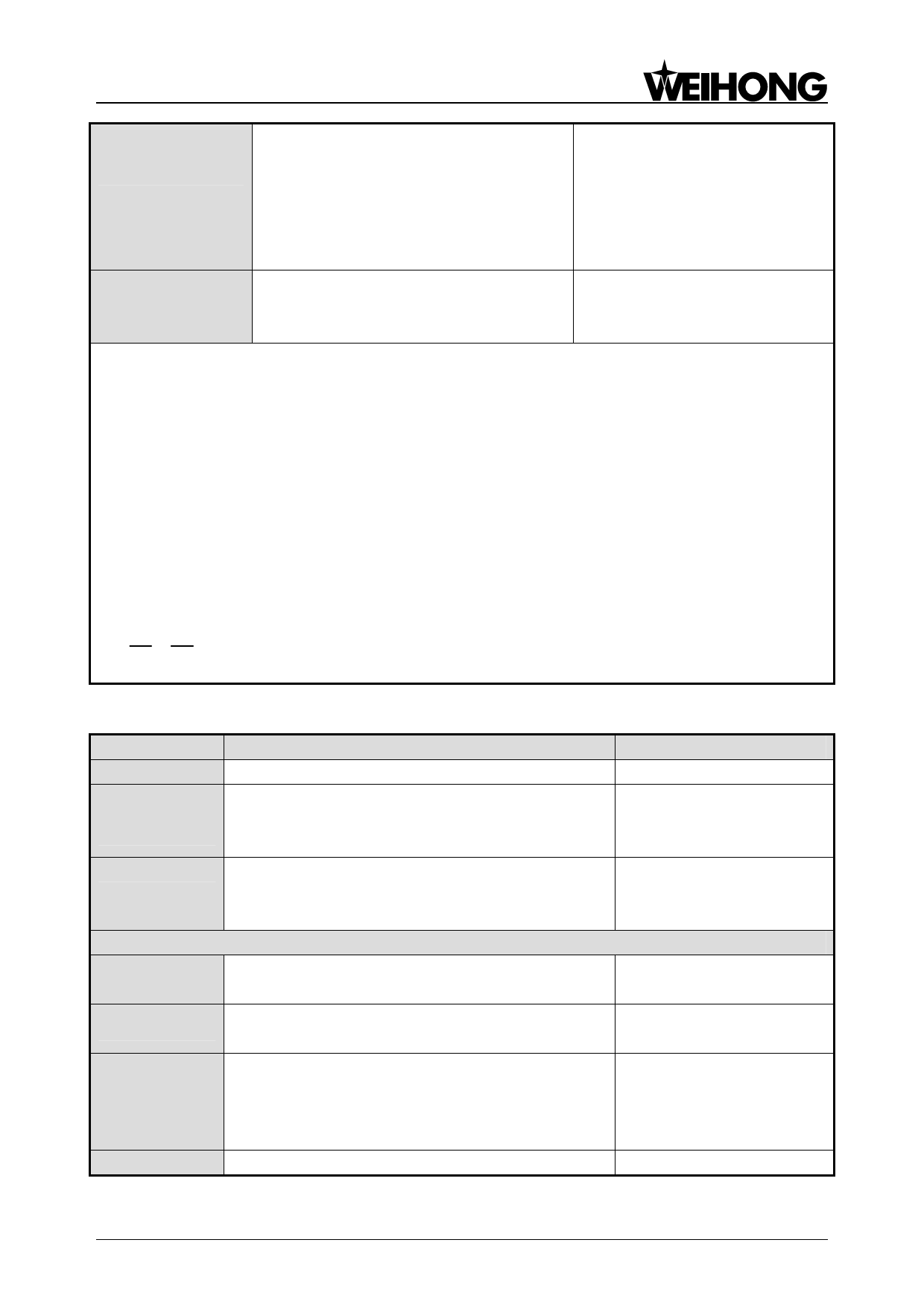

Parameters Related with Machine Tool Debugging

Parameter

Axis OutpDir

Machine

Stroke

Pulse Equiv.

REFP Speed

REFP Dir

Retract Dist

Sign of BK

Meaning

The motion direction of each axis

The valid motion stroke of machine tool, i.e. the

valid processing range of machine tool along X/Y/Z

axis

The worktable stoke per pulse sent by the CNC

device or the rotary degree of rotate axis, i.e. the

least distance the CNC system can control

REF. Point Set

The speed of rough positioning in backing to

mechanical origin

The direction of rough positioning in backing to

mechanical origin

The additional motion distance after fine positioning

stage in backing to mechanical origin; positive value

moving towards positive direction, negative value

towards negative direction

Whether to eliminate the sign of backing to

Setting range

Positive; Negative

Set according to the actual

machine tool

0.00009~999.0mm/p

0.001~max. speed of

machine tool

Positive; Negative

0~10000mm

Yes: eliminate

Specialized, Concentrated, Focused

37