EasyRoute Control Panel is based on Weihong NK105 CNC Integrated Machine OEM http://am.co.za/router/panel

上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

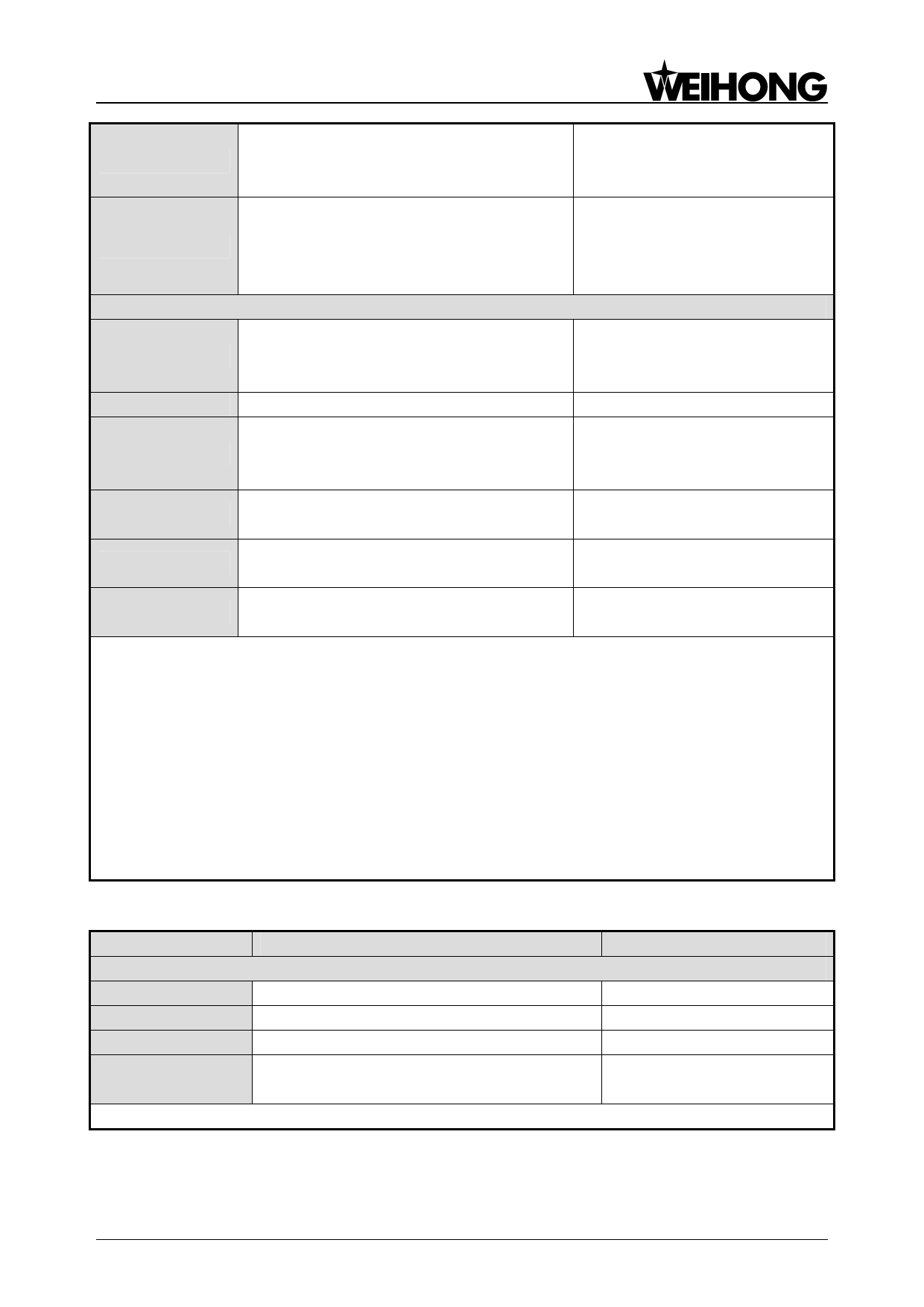

Retract amount after each feed in

Retract Amount high-speed reciprocating chip removal 0~99999999

mode

If this parameter is set as “Yes”, the

Select Tool No.

machining will go on in terms of the

specified tool No. in the machining file and

Yes: valid

No: invalid

only this file will be processed.

Dxf Params

It sets the tool lifting height of Z axis during

Lifting Height rapid traverse of machine tool when a DXF 0~99999

file is being processed.

Process Depth It specifies the processing depth for 2D files. -99999~0

1st Point as 0

It sets whether to set the first point as

workpiece origin when DXF file is Yes: valid

No: invalid

processed.

The system will not process the next shape

Shape Process until the last shape is finished.

Yes: valid

No: invalid

Bottom Process

Valve operation is enabled only when [3D

cutting] is on the workpiece surface.

Yes: valid

No: invalid

Metric Size It forcibly sets dxf file as metric size.

Yes: metric size

No: imperial size

These two groups of parameters are specially aiming at ENG files and DXF files.

The system treats each tool lifting as a process step. If several shapes, with each shape including

several steps, are to be machined, the second step will not machined until the first step of all the

shapes are finished under the condition of the parameter “Shape Process” set as “No”.

If the parameter “1st Point as 0” is set as “No”, the zero coordinate of DXF file will be regarded as

workpiece origin in processing; if “Yes”, the self-defined point in the DXF file will be treated as

workpiece origin. For instance: when drawing a picture with CAD, user can define a point (this point

will not be processed) freely in the picture (it’s better if the point is near or within the picture); and then

the system will treat it as workpiece origin. If there are several points in the DXF file, the system will

think the first drawn point as workpiece origin.

Tool Change Parameters

Parameter

ATC Capacity

Current Tool No.

Tool Offset

Tool Change Tip

Meaning

Tool Change

Capacity of tool magazine

Tool No. currently used

Modification to the tool offset along each axis

Whether to send prompt when there is tool

change command in the file

Setting range

1~20

1~value of ATC Capacity

X/Y/Z: -10000~10000

Yes: valid

No: invalid

Specialized, Concentrated, Focused

35