EasyRoute Control Panel is based on Weihong NK105 CNC Integrated Machine OEM http://am.co.za/router/panel

上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

Workpiece Coordinate System

As a set of right-hand coordinate system for the programmer, workpiece coordinate system is

used in programming. To establish it, the programmer can select a given point on the workpiece as

the origin (also called program origin). The origin of workpiece coordinate system (namely the

workpiece origin) is fixed relative to a certain point on the workpiece, so it can be floating with respect

to the origin of mechanical coordinate. The origin of workpiece coordinate system should be selected

meeting such conditions as simple programming, simple dimension conversion and small machining

errors caused.

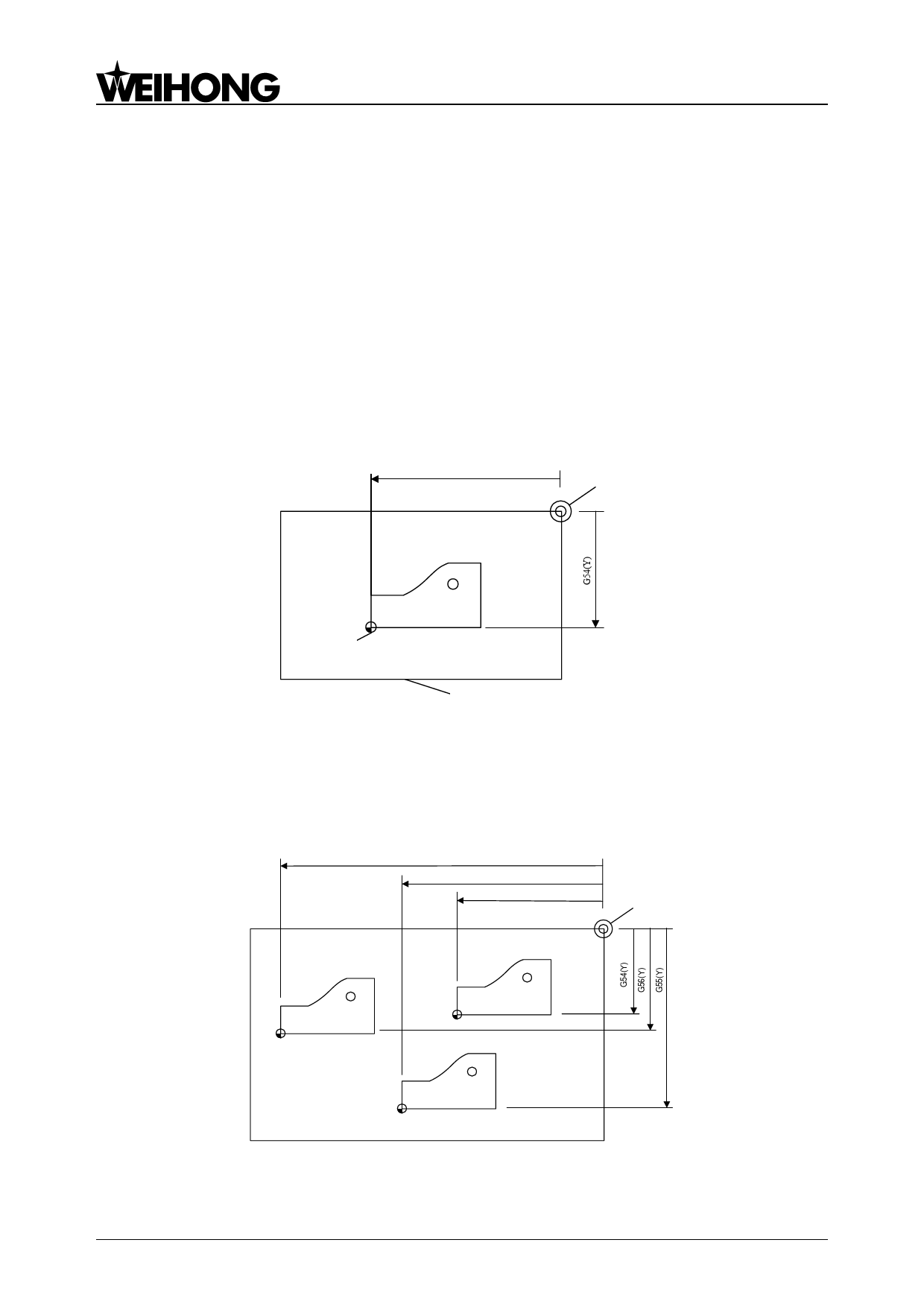

Workpiece offset corresponds to the coordinate systems G54, G55, G56, G57, G58 and G59.

After the system is opened, the default coordinate system is G54, and the relation between workpiece

offset and mechanical coordinate system is as shown in Fig. 4-2.

G54(X)

Machine

Origin

Workpiece

Origin

Workpiece

Limit of Axial Motion

Fig. 4-2 The relation between workpiece offset and mechanical coordinate system

One, two or several workpiece offsets can be used in the machining program. As shown in Fig.

4-3, three workpieces are installed on the work table, so each workpiece has a workpiece origin

corresponding to the G code of workpiece coordinate system. Drill a hole on each of the workpiece,

with calculation depth as Z-0.14, and the programming example is as follows.

G56(X)

G55(X)

G54(X)

Machine

Origin

Workpiece

Workpiece

Workpiece

Fig. 4-3 Example figure

12

Specialized, Concentrated, Focused