- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- Component Manuals

- VICSION VS500 Inverter Manual.pdf

- Page 94 of 113

90 VICSION VS500

8. TROUBLESHOOTING AND MEASURES

8.1 Protective functions and Countermeasures

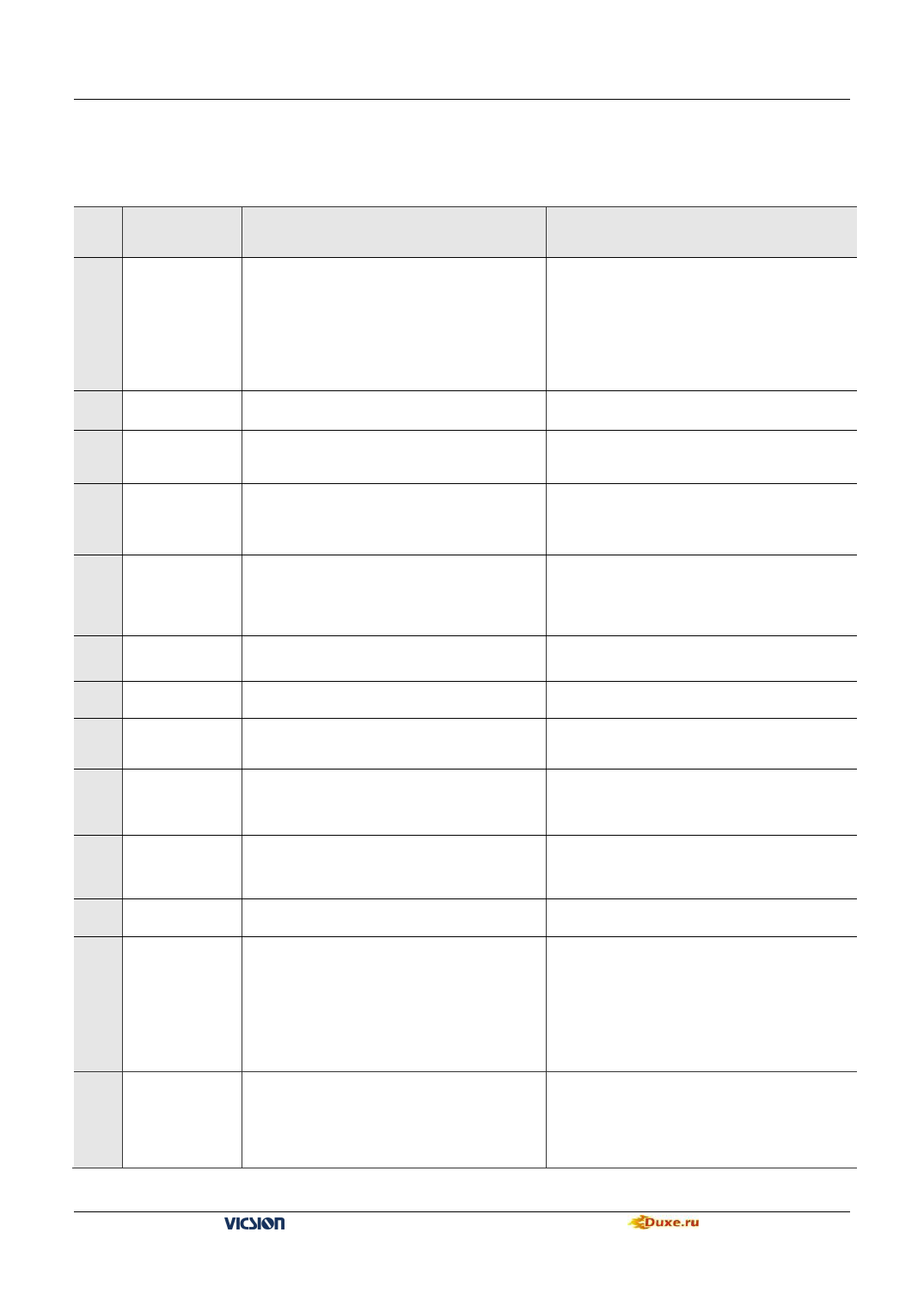

Code

Faults

Probable Causes

Solutions

Fu.01

Over-current during

Acc

1、Acceleration time is too short.

1. Prolong the acceleration time

2、V/F curve is not suitable

2. Descend the torque boost or adjust the V/F curve

3、You hasn’t set the right motor parameters

3. Input motor’s parameter once again and do

4、User start rotating motor, but doesn’t set function of self-determination to parameter.

detect speed and restart.

4. To set function of detecting speed and restart

5、Value of torque boost set too high.

5. To decrease voltage of torque boost

6、Power grid voltage is too low

6. Check power grid voltage, and reduce power then use

Fu.02

over-current

during Dec

Deceleration time is too short.

Prolong the deceleration time

Fu.03

Over-current during 1. Load occurs mutation

Running or stopping 2. Power grid voltage is too low

1. Decrease load fluctuation

2. Check power supply voltage.

Fu.04

over-voltage

during Acc

1.Input voltage is too high

2. Power supply is switched on or off frequently.

1. Check power supply voltage

2.Decrease setting value of F4.11

3. Control the on-off of inverter by the control

terminal

Fu.05

over-voltage

during Dec

1. Deceleration time is too short.

2. Input-voltage is abnormal

1. Extend the deceleration time

2. Check power supply voltage

3. Install or select the brake resistance

Fu.06

over-voltage

during running

1. Power supply is abnormal

2. There are energy feedback load

1. Check power supply

2. Install or select brake resistor

Fu.07

over-voltage

during stop

Fu.08

Under-voltage

during running

Power supply is abnormal

1. Power supply is abnormal

2. There is great fluctuation of load into electric

network.

Fu.09

protective action of

inverter

1. Output is short-circuit or ground

2. Load is too heavy

Check power supply voltage

1. Check power supply voltage

2. Provide the power supply separately

1. Check wiring

2. Reduce the load

3. Check whether brake resistor is

short-circuit

Fu.10 Output grounding

1.The output terminal of inverter grounds

1. Check the connecting wire

2. The wire is too long between inverter and motor and 2. Shorten the connection wire or reduce the

the carrier frequency is too high.

carrier frequency.

Fu.11

Interfere of inverter

Fault action caused by disturbance of

electromagnetism

Fu.12

1. Load is too heavy.

2. Acceleration time is too short.

3. Torque boost is too high or V/F curve is not

Inverter over-loading suitable.

4. Voltage of Power supply is too low

5. User start rotating motor, but doesn’t set

function of detecting speed and restart.

Fu.13

Motor over-loading

1. Load is too heavy.

2. Acceleration time is too short.

3. The setting of protection factor is too small

4. Torque boost is too high or V/F curve is not

suitable.

Add absorb circuit around inverter

1. Reduce the load or replace with higher

capacity inverter.

2. Prolong Acc time.

3. Decrease the torque boost or adjusting

V/F curve.

4. Check Voltage of Power supply

5. To set function of detect speed and

restart

1. Reduce the load

2. Prolong Acc time

3. Increase the over-loading protection

factor of motor( [F4.12])

4. Decrease torque boost voltage and adjust

V/F curve.

VS500 series of general purpose inverter Duxe.ru