- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- Component Manuals

- VICSION VS500 Inverter Manual.pdf

- Page 82 of 113

78 VICSION VS500

7. SPECIAL FUNCTIONS FOR DRAWING MACHINE

7.1 Overview

On the mechanical equipment for metal products, paper making and wires and cables, etc., the tension stability must be

ensured during continuous drawing out fabrics or wires from the machines and during winding, to ensure the product

quality. For the special application requirements of the drawing machine, E380 series inverter (program version of

above V1611) is built in with the dedicated control module, realizes highly stable winding control through the advanced

PID control with feed forward compensation, and provides multiple dedicated functions such as disconnection

protection and stop at fixed length.

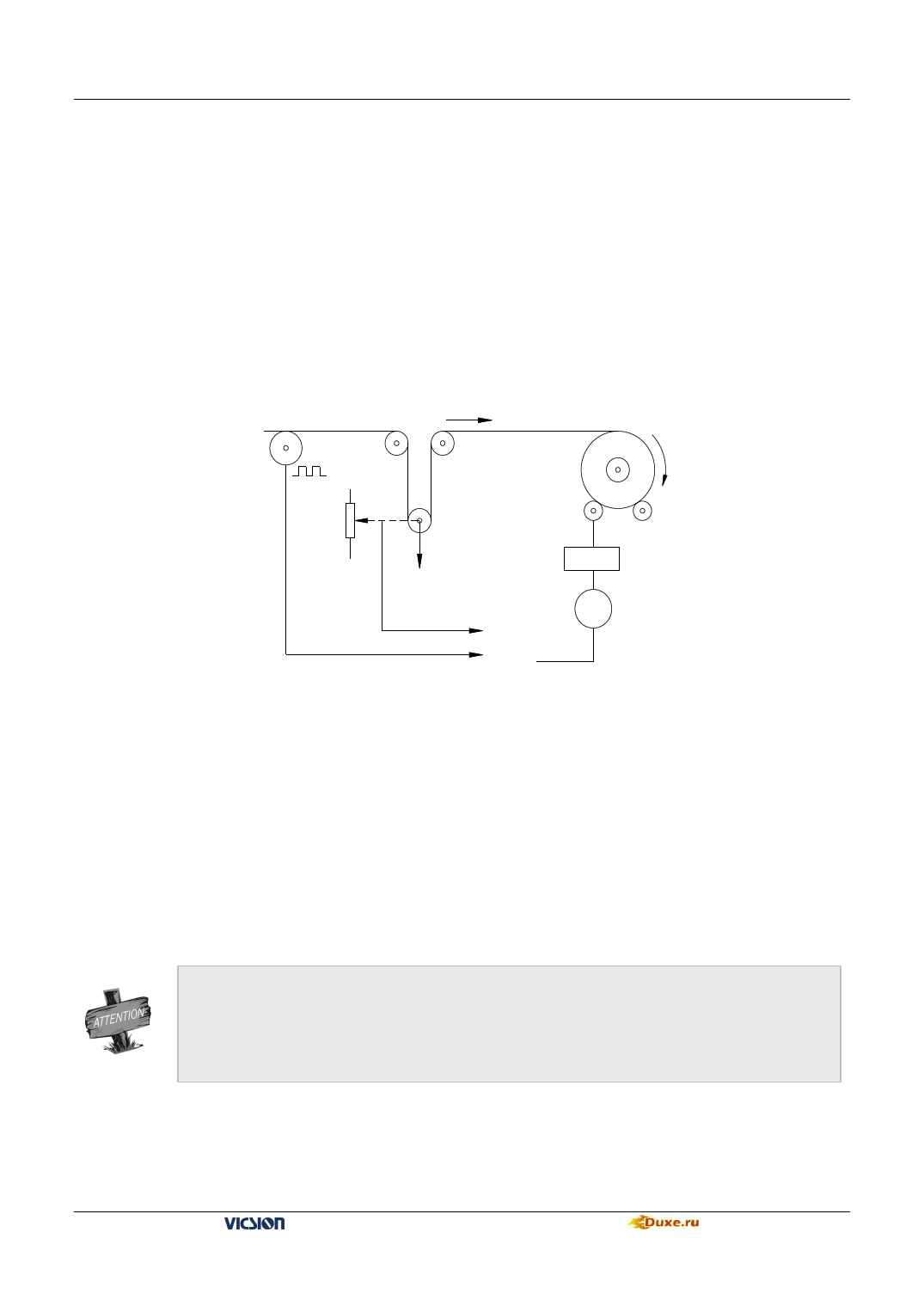

Typical traction application of drawing machine specialized inverter, show as Fig. 7-1:

Tension

Speed shift mechanism

Pendulum feedback

M

Linear speed input

Inverter

Fig. 7-1 Typical Traction Application

7.2 Selection of dedicated functions of drawing machine

Change the single-digit setting of parameter [F0.0] to switch between the general running mode and drawing machine

dedicated mode and enable the corresponding parameter table and software functional module. The drawing machine

dedicated function is a controlled function, and the dedicated authorization code is required for enabling this function.

LED single-digit definition of parameter [F0.0]:

0: General mode

1: Drawing machine dedicated mode

When setting of this parameter is changed, it will automatically start one parameter initialization process, and switch to

the corresponding parameter environment

In the application of dual inverter wire drawer:

Only the rolling inverter needs to work in the dedicated mode and the main drawing inverter works in the

general mode.

When the rolling inverter is used for the first time or changed the using equipment, the dancer arm raise delay

may be too quick or too slow, which is caused by self-correcting of parameter

VS500 series of general purpose inverter Duxe.ru