- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- Component Manuals

- VICSION VS500 Inverter Manual.pdf

- Page 54 of 113

50 VICSION VS500

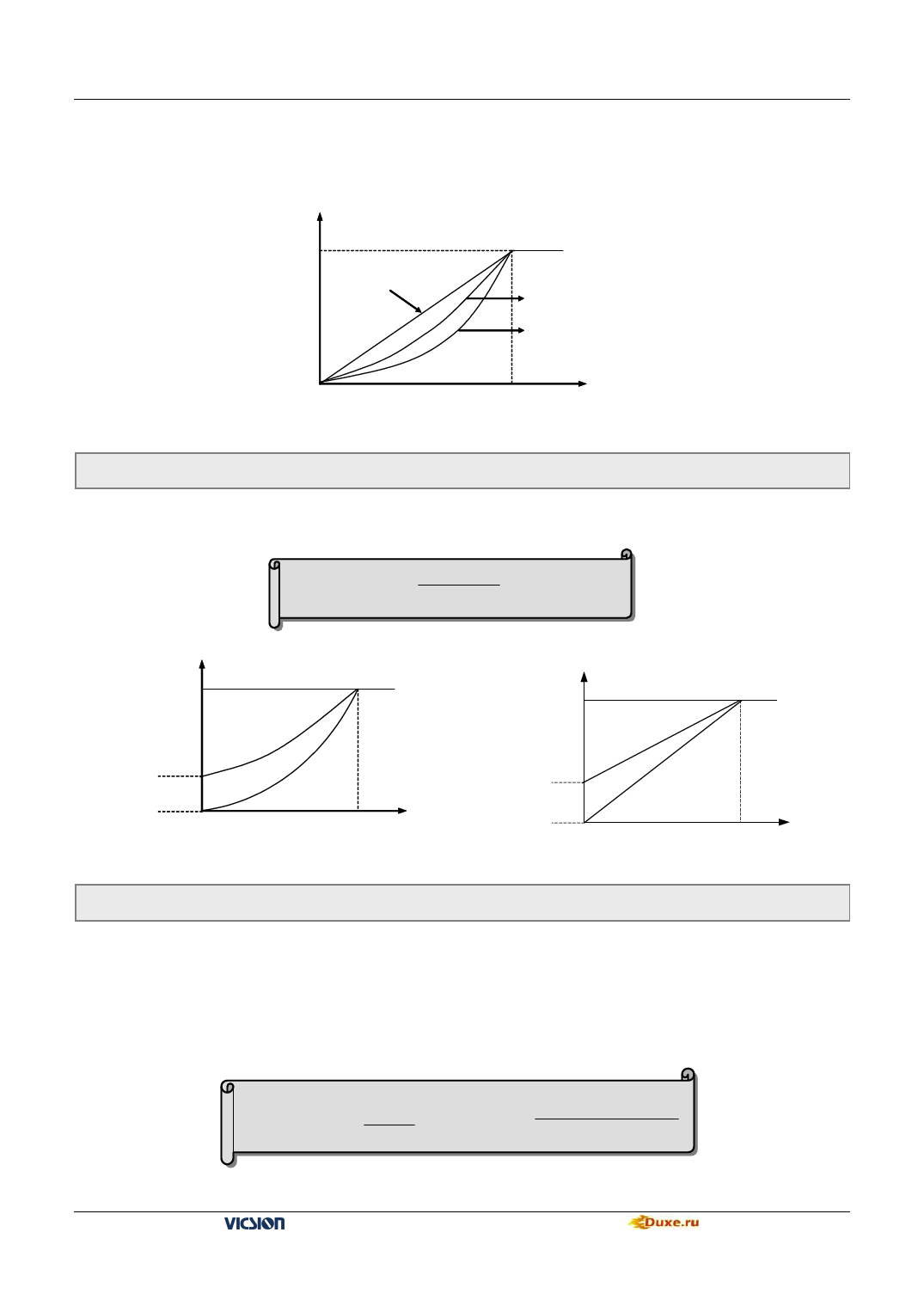

fan, pump, etc. If there is some unstable phenomenon in light-load running, please switch to run in the decreasing

torque curve 1.

3: V/F user-defined curve

It is used for setting user-defined curve which user need

Voltage

[F1.4]

The max

tput voltage

Constant torque curve

Decreasing torque

curve 1

Decreasing torque

curve 2

Fig. 6-4 V/F curve

[F1.3]

f

Basic running freq

F1.1 Torque Boost(output voltage at 0 Hz)

Setting range:0.0 ~ 20.0(%)

It is used for improving the low-frequency torque character. In low-frequency running, it will make boost

compensation for the output voltage of inverter, as shown in Fig.6-5.

Boost voltage =

[F1.1]

× [F1.4]

100

[F1.4]

Voltage

Voltage

[F1.4]

[F1.1]

Boost

voltage

f

[F1.3]

(1)Decreasing torque curve

Fig.6-5 Torque boost

F1.2 Torque boost pattern

[F1.1]

Boost

voltage

f

[F1.3]

(2)Constant torque curve

Setting range:0 ,1

0:Manual

Torque boost voltage is completely controlled by F1.1. There are two features: voltage will steady boost. And motor will

easily magnetic saturation when light-load.

1:Automatic

Torque boost voltage is changed with the stator current of motor. The boost voltage is higher with the stator current

higher.

Boost voltage = [F1.1] ×[F1.4]× Inverter’s output Current

200

2×inverter’s rated current

VS500 series of general purpose inverter Duxe.ru