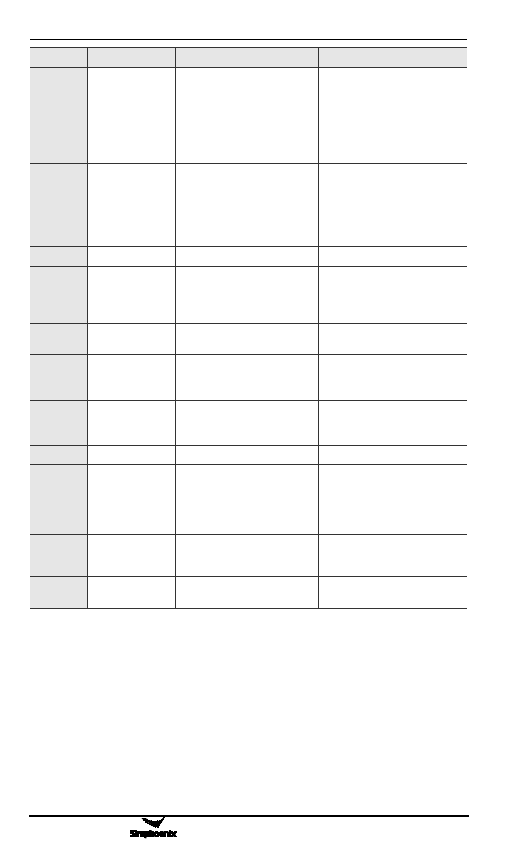

76 Fault Diagnosis And Countermeasures

Fault Code Fault Description

Possible Reasons

Fu.13

Motor overload

1. The load is too large.

2. The acceleration time is

too short.

3. The protection factor

Setting is too small.

4. The torque boost is too

high.

Fu.14

1. Air duct obstruction

Inverter overheat

2. The environment

temperature is too high.

3. The fan is damaged.

Fu.15

Reserve

Fu.16

External

The exterior fault input

equipment fault terminal is ineffective.

Fu.17

~Fu.19

Fu.20

Fu.21

Fu.22

Fu.23

Reserve

Current

detection error

The current detection

devices or circuit is

damaged.

Temperature The temperature sensor is

sensor fault off-line.

Reserve

PID feedback

off-line

1 The feedback signal is

lost.

2. The setting of off-line

detection threshold value

is not appropriate.

Solutions

1. Reduce load.

2. Extend the acceleration

time.

3. Increase the overload

protection factor of motor.

4. Reduce torque boost.

1. Clean air duct or improve

ventilation condition.

2. Improve the ventilation

condition and reduce the

carrier frequency.

3. Change fan.

1. Check the exterior

equipment.

2. Disconnect the external

fault input terminal.

1. Check socket line.

2. Ask for manufacturers’

assistance.

1. Check socket line.

2. Ask for manufacturers’

assistance.

1. Check line.

2. Reduce threshold value of

off-line detection.

Fu.24

~Fu.39

Reserve

Fu.40

Internal data The read-write errors of

EEPROM error control parameters

Ask for manufacturers’

assistance.

7.2 Fault record query

The series of inverters recorded the recent fault code occurred in the last four

times and the inverter output parameters of the last fault; query of these

information will contribute to find fault causes.

E500 Series Universal Low-Power Inverter