MODBUS Protocol 101

Appendix III: Brake resistor selection

In running process of inverter, in case that controlled motor speed falls too fast

or motor load shakes too fast, the electromotive force will charge inverter

internal capacitance through inverter in reverse direction, therefore, voltage at

two ends of power module will be boosted to damage inverter possibly. The

inverter internal control will be suppressed based on loading condition; in case

of brake performance failing to meet customer requirements, it’s necessary to

connect with external brake resistor to realize immediate release of energy. The

external brake resistor belongs to energy-consumption brake mode, which will

consume all energy on power brake resistor. Therefore, selection of power and

resistance value of brake resistor must be reasonable. The following content

refers to introducing brake resistor power and resistance value recommended to

be employed for SIMPHOENIX inverter. Based on loading condition, user can

modify value properly in line with the range specified by SIMPHOENIX

inverter.

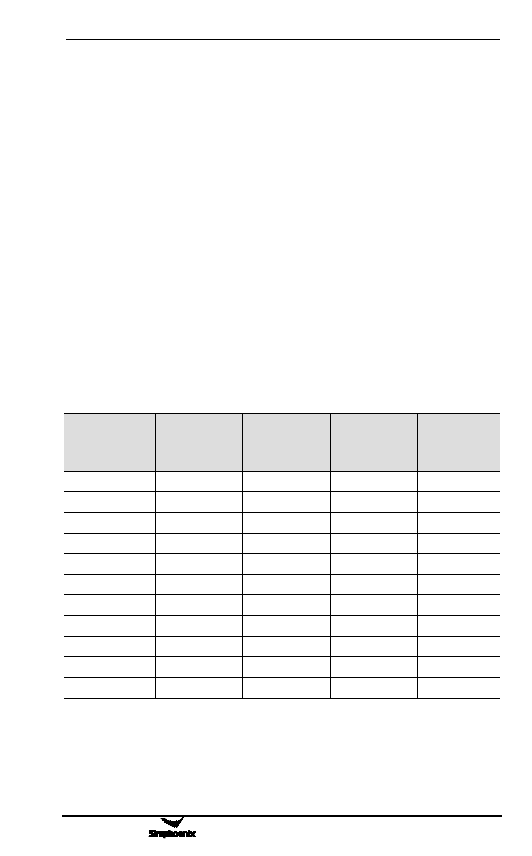

Inverter model

E500-2S0004

E500-2S0007

E500-2S0015

E500-2S0022

E500-2S0030

E500-2S0040

E500-4T0007

E500-4T0015

E500-4T0022

E500-4T0030

E500-4T0040

Applicable

motor (KW)

0.4

0.75

1.5

2.2

3.0

4.0

0.75

1.5

2.2

3.0

4.0

Brake resistor

power (KW)

0.1

0.1

0.2

0.2

0.4

0.4

0.1

0.2

0.4

0.4

0.5

Brake

resistance

value (Ω)

150

100

70

50

40

35

400

300

200

150

125

Braking

torque (%)

100

100

100

100

100

100

100

100

100

100

100

E500 Series Universal Low-Power Inverter