HSD

Your tool, of whatever shape, can be considered equivalent to a cylindrically-shaped tool (like the

one illustrated next to the charts on the following pages). From the charts, choose the curve

corresponding to the position of the centre of gravity of your tool, and read the maximum rpm

corresponding to the weight of your tool.

6.7.2.2 Procedure for reading the charts

The charts on the following pages are approximate, in that they do not take into

account (because HSD S.p.A. cannot know this information) of the machining operation

i

parameters, the specific characteristics of the tool used by the customer, or the particular

type of material being worked:

it is the user's responsibility to evaluate each time the maximum speed that allows

him to work safely.

1. Identify the chart relating to your electrospindle.

2. On the basis of the distance “X” between the spindle nose and the centre of gravity “G” of the

tool+tool holder assembly, choose one of the curves. If the “X” measured on your electrospindle

does not appear on the chart, choose the curve associated with the “X” that is the next

measurement bigger (see example).

3. Corresponding to the weight of the tool+tool holder assembly, read the value of the maximum

speed.

4. If the weight or the distance of G are greater than those envisaged by HSD, it will be the user's

responsibility to evaluate each time the maximum speed that allows him to work safely.

i

If you are concerned that the tool is too big and could damage the electrospindle, contact

HSD Customer Service

EXAMPLE 1

On an ES929 L HSK F63 SHORT NOSE, you want to use a tool+tool holder assembly with an

overall weight of 3.5kg (including the ring nut and mill collet); the distance between the spindle

nose and the centre of gravity “G” of the tool+tool holder assembly is “X”=120mm:

1. The chart relating to this particular electrospindle is that in paragraph 6.7.2.6

2. With no specific curve for “X”=120mm, it is necessary to refer to the yellow curve associated

with “X”=130mm

3. Corresponding to the weight of 3.5kg, you can read the maximum speed, when empty, of

10000 rpm.

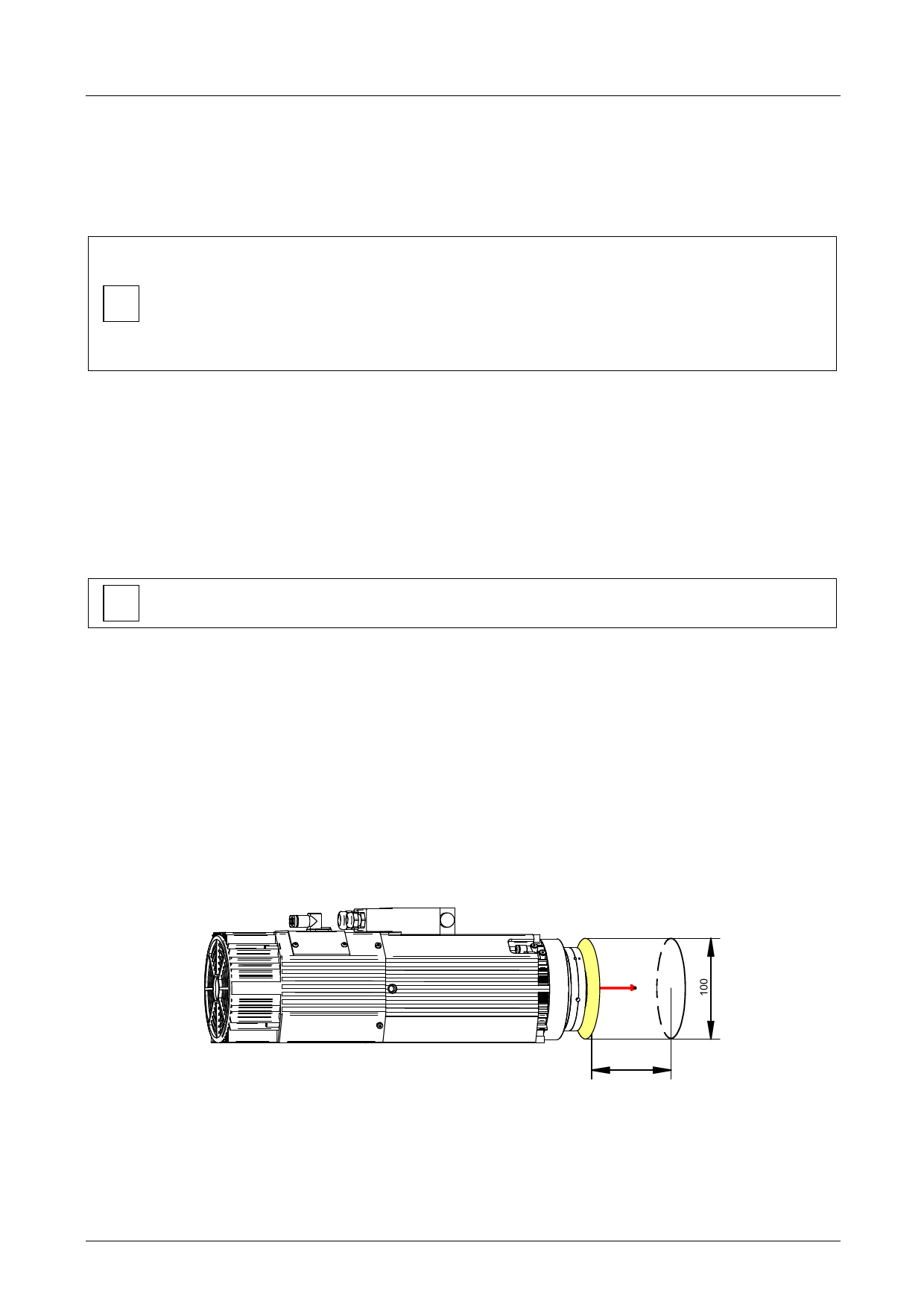

EXAMPLE 2

On an ES929 L ISO 30 SHORT NOSE, you want to use a pack of milling cutters comparable with a

cylinder of diameter 100mm, length 100mm and overall weight 4.5kg:

XG

100

1. b=h/2=100/2=50mm

2. The tool is comparable with a single elementary part (cylinder), so X=b=50mm

3. The chart relating to this particular electrospindle is that in paragraph 6.7.2.3

4. You must refer to the red curve associated with “X”=50mm

5. Corresponding to the weight of 4.5kg, you can read the maximum speed, when empty, of

14000 rpm.

5801H0056 _______________________________________________________________ 94/183