HSD

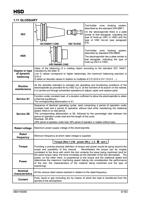

6.6.1 Installation of the tie-rod HSD 0804H0009 in the cone ISO30 DIN69871

Carefully clean the tie-rod and the tie-rod housing in the cone ISO30.

Cover the thread of the tie-rod with high resistance, thread-blocking liquid (LOCTITE 270 or

another equivalent product).

Tighten the tie-rod to the cone with a torque of 62 Nm.

Leave the cone to rest, to allow the thread-blocking liquid to adhere (12 hours with LOCTITE

270, or depending on the manufacturer's indications if using an alternative, equivalent thread-

blocker).

The use of non-original HSD tie-rods, or incorrect installation, may cause the tool-holder

cone to fly off.

It is forbidden to use ISO or HSK tool-holders not conforming to the conditions described

above; failure to observe these instructions represents a source of risk of breakage or

incorrect hook-up of the tool-holder cone, with serious risks for the user.

6.6.2 General recommendations for the tool-holder cones

IMPORTANT:

The choice of tool-holder is a determining factor for safety purposes.

The conical surfaces of the tool-holder and its housing on the spindle shaft must be kept

thoroughly clean in order to permit secure hooking-up (see section 7 "Scheduled maintenance"

).

During machining operations, be sure to avoid any contact between the non-cutting rotating

parts and the piece being machined.

The seat of the tool-holder cone must always be protected against any impurity that may come

in: use a closing device or a tool-holder cone.

At the end of the working day, always remove the tool-holder cone from the electrospindle, to

avoid any problem of it sticking. Replace it with a clean tool-holder cone at room temperature,

to protect the inside of the electrospindle from the outer environment.

Only for HSK versions: do not set the electrospindle in rotation without the tool-holder installed.

This would compromise the balancing and working of the collet.

6.7 TOOL

The tools must have a degree of dynamic balancing of G = 2.5 or better (standard ISO1940) at the

maximum rated speed of the electrospindle.

When selecting the tool, it is essential to pay attention to the following recommendations:

Always use properly sharpened tools, locking them correctly in the respective tool-holder.

Never use deformed or damaged tools, tools with missing parts or tools that are not perfectly

balanced.

Before inserting the tool in the respective collet, always check that all the surfaces are free

from damage and thoroughly cleaned.

The essential requirements for using a tool at high speed are:

- a compact, short, lightweight tool

- precise, and with any inserts blocked with a high degree of safety

- balanced and coupled symmetrically with the tool-holder

- with bits near the rotation axis

5801H0056 _______________________________________________________________ 90/183