HSD

6.4.1 Technical characteristics of the electric fan

Power supply

Frequency

Input power

230 10% V AC

50 Hz

60 Hz

45 W

39 W

6.5 TOOL-HOLDER LOCKING AND EXPULSION DEVICE

The blocking and expulsion of the tool-holder is carried out by the single-acting movement of a

pneumatic piston, activated with compressed air.

The tool-holder is mechanically blocked with elastic springs.

electrospindle

model

ISO30

HSK F63/E50

HSK E40/F50

HSK E63/F80

axial force

on the tool-holder

3200 N ± 10%

11000 N ± 10%

6800 N ± 10%

18000 N ± 10%

expulsion of the tool-holder

cone

0.5 - 0.9mm

0.5 - 0.6mm

0.5 - 0.6mm

0.5 - 0.6mm

The axial force exerted on the tool-holder by the blocking system is guaranteed constant

i for a minimum duration of 2,000,000 cycles of tool change

1 tool change cycle = tool blocked / tool released / tool blocked

All HSD electrospindles have a mechanical reaction system that neutralises the axial

i force of the piston on the shaft during the tool changing phase, guaranteeing the integrity

of the precision bearings.

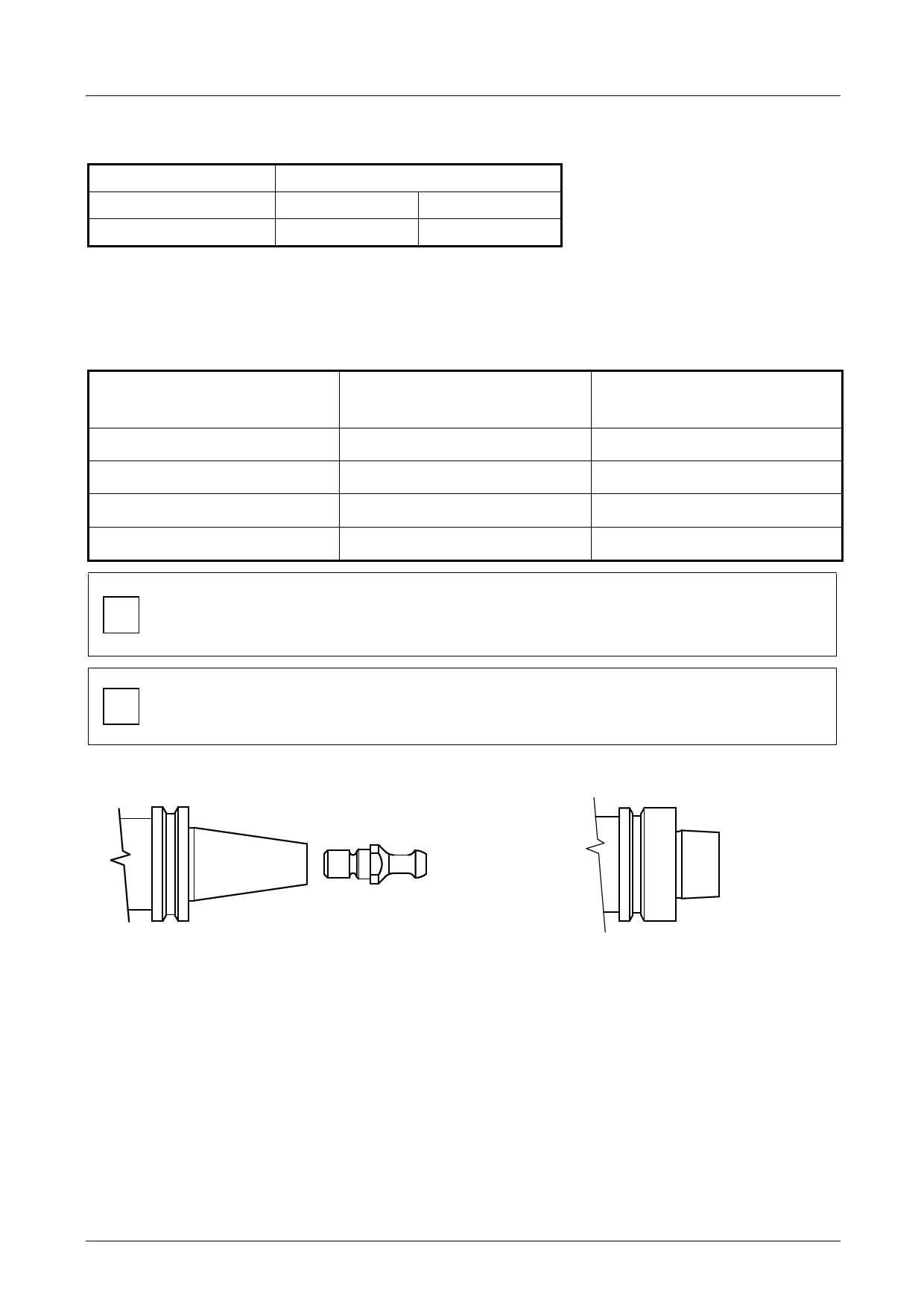

6.6 TOOL-HOLDER CONE

Figure

6.1

CONE ISO30

DIN69871

HSD TIE-ROD

0804H0009

Figure

6.2

HSK DIN69893 CONE

The geometry of the conicity must respect standard DIN69871 for ISO30 cones, and standard

DIN69893 for HSK cones.

The tool-holder cone ISO30 must have an AT3 precision rating;

Avoid the presence of plugs, slots, or other forms affecting the dynamic balancing of the tool-

holder;

At the maximum rated speed of the electrospindle, the level of dynamic balancing must be G =

2.5 or better (ISO1940 standard);

The balancing must be carried out with the tool-holder assembled (cone, mill collet, ring nut,

tool);

The tie-rod (also known as the shank) of the cone ISO30 must only be the one supplied by

HSD (code 0804H0009).

5801H0056 _______________________________________________________________ 89/183