HSD

5 GENERAL CHECKS AFTER INSTALLATION

5.1 CHECKS BEFORE THE START-UP

5.1.1 Positioning

Check the conformity with the specifications of section 4.3.1

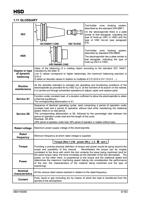

5.1.2 Pneumatic connections

Refer to section 4.4and check the correctness of the pneumatic connections, the pressure

levels used and the purity of the compressed air.

The pressurisation air must always be present, even when the electrospindle is stopped.

With the spindle at standstill and the tool holder inserted, check there is a uniform, continuous

outlet of air from the area of the spindle nose around the shaft.

The air jet for cleaning the cone must be present during the tool change phase.

5.1.3 Electrical connections

The earthing of the electrospindle (see section 4.6.1.1) must be connected to the

earthing of the machine.

The thermal alarm must activate a procedure for protecting against the overheating of

the electrospindle coils (see section 6.9.4 ).

5.1.4 Programming the inverter

The maximum voltage set on the inverter must correspond to the rated value indicated on the

motor rating plate;

The frequency value at which the maximum voltage (rated frequency) is to be attained must

correspond to the value indicated on the motor rating plate;

The maximum speed set on the inverter must correspond to the value indicated on the motor

rating plate;

The maximum direct current supplied to the inverter must correspond to the rated current

indicated on the motor rating plate;

If it is considered necessary to check the other parameters of the inverter, please contact HSD

S.p.A.

5.2 START-UP CHECKS

Only run the electrospindle if the signal on pin no.2 of the signals connector is “ON”.

i

The “ON” condition corresponds to an output equal to the supply voltage of the sensors;

the “OFF” condition corresponds to an output of 0V.

Only for HSK versions:

it is forbidden to run the electrospindle without the tool-holder inserted.

the control sensors must intervene according to the logic described in section 6.9.2;

the tool changing cycle may only start when the shaft is at a standstill;

check the correct working of the cooling system;

without making any machining operations, carry out the preheating cycle described in section

6.3.

5801H0056 _______________________________________________________________ 87/183