HSD

4 INSTALLATION AND INITIAL START-UP

4.1 CHECK

Before carrying out any operations, CHECK:

that no part of the electrospindle has been damaged during transport and/or handling;

that connectors are not damaged.

4.2 PREPARATION OF THE AUXILIARY SYSTEMS OF THE PLANT

The preparatory work (e.g. providing electricity, air systems etc.) is the responsibility of the

customer.

The electric power lead of the electrospindle must have the necessary transmission power. The

connection to the electricity mains supply must be carried out by qualified personnel. You are

reminded that the customer is responsible for all the electricity supply as far as the connectors of

the electrospindle.

The customer is also reminded of the need to provide all the safety conditions necessary for the

“earthing” of the electrospindle.

The earthing system must conform to the standards in force in the country of installation and must

be inspected at regular intervals by qualified personnel.

For the connections, see the sections below.

4.3 MECHANICAL CONNECTIONS

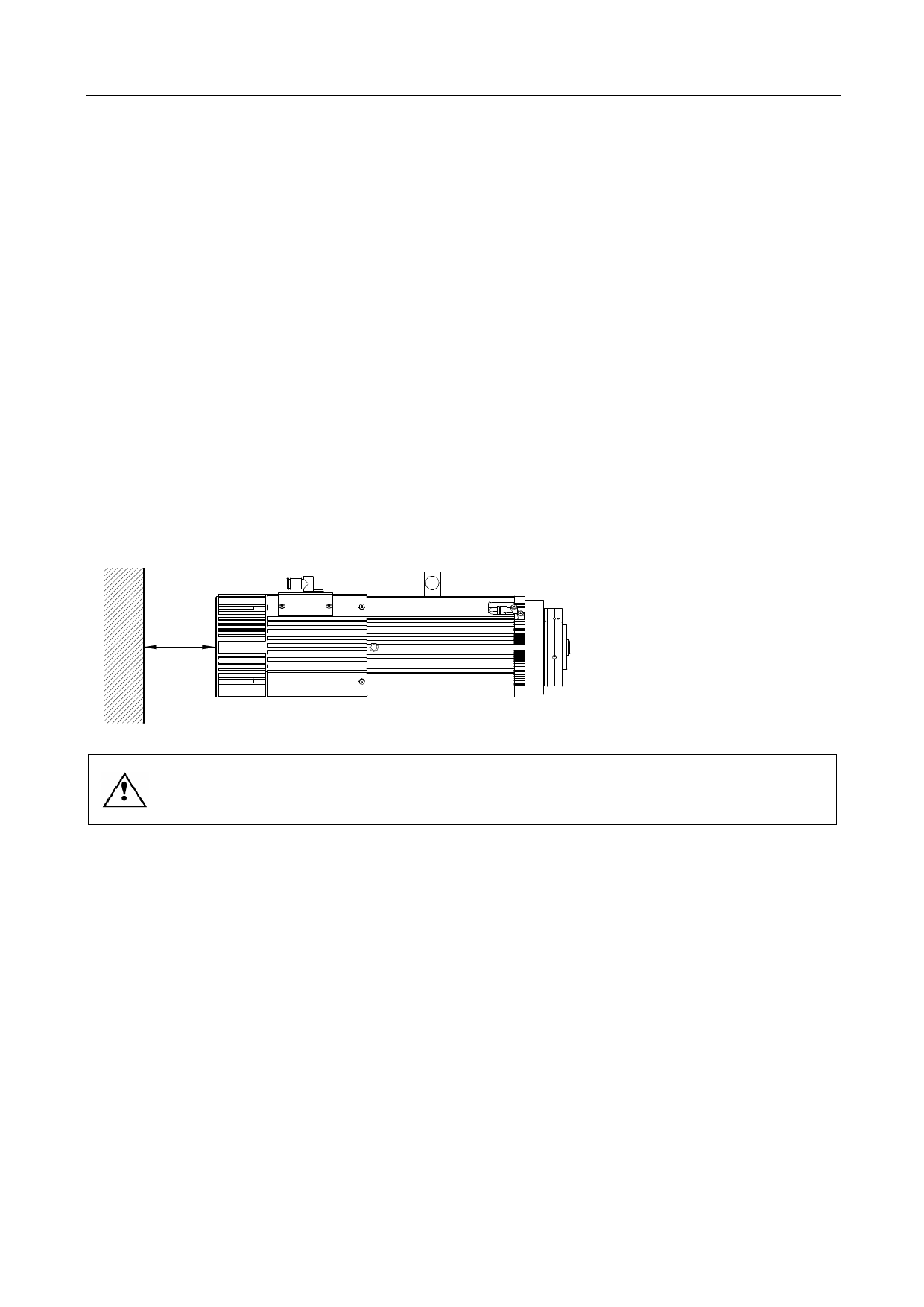

4.3.1 Positioning of electrospindle (versions with electric fan)

When choosing the location for

the electrospindle, ensure a

100

clearance of at least 100mm

from the grille of the electric

fan, so as not to obstruct the

flow of cooling air.

Figure4 .1 Minimum clearance of the fan

IP protection rating of the electric fan: 21; (IP protection rating of the electrospindle: 54).

Ensure that the electric fan sucks in sufficient air for its IP protection rating,

as otherwise it may be damaged.

5801H0056 _______________________________________________________________ 67/183