- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- Component Manuals

- HSD Spindle Instructions for Use.pdf

- Page 154 of 183

HSD

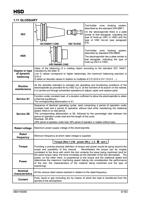

Reassemble the phonic wheel.

Warning:

Align the tang of the “Z” zero with the notch on

13. the shaft.

Z

After fixing the phonic wheel, check that the

dynamic balancing level at maximum speed is

G=2.5 or better.

If this is not the case, contact HSD.

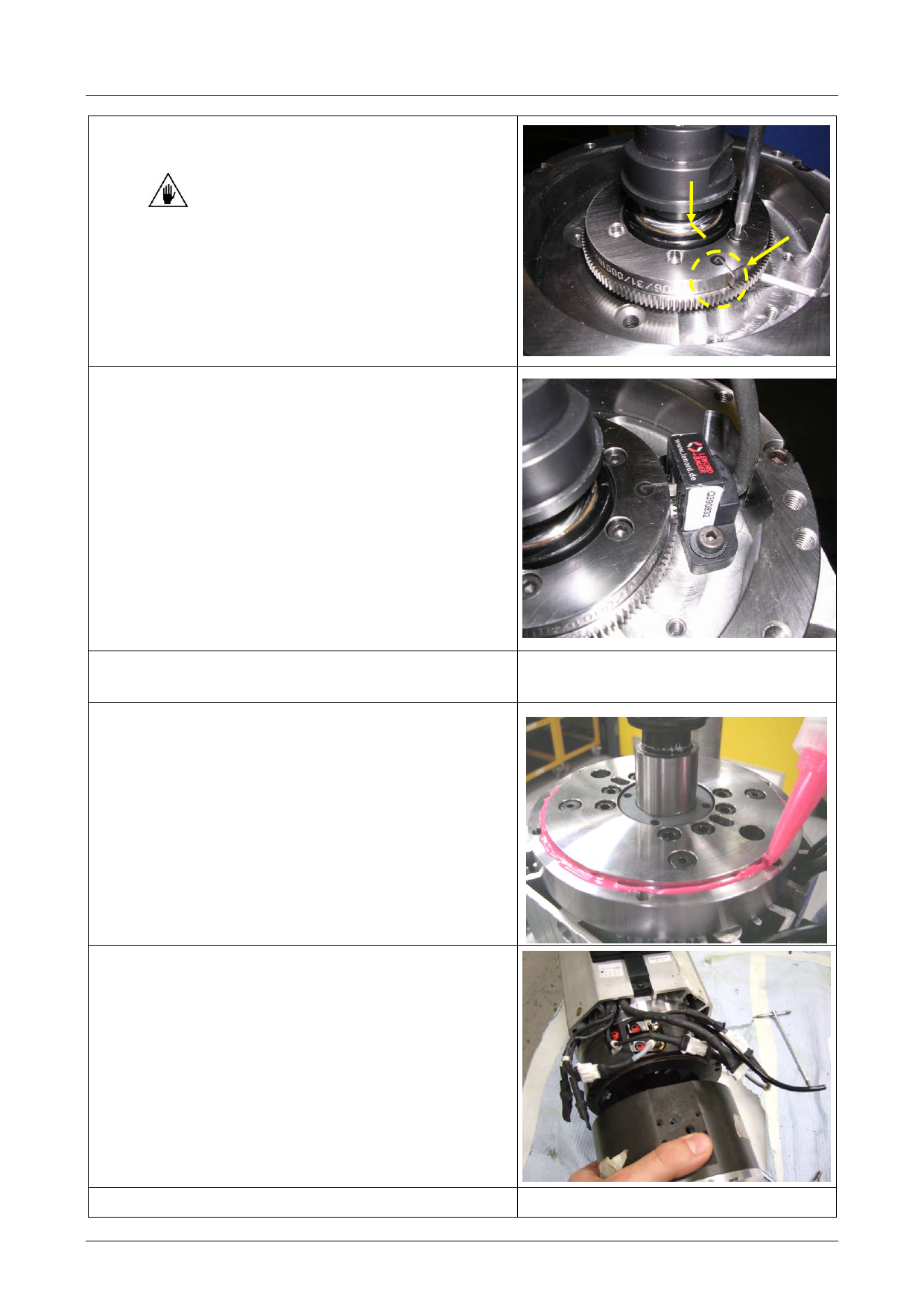

To assemble the encoder reader at the right

distance, insert a 0.2mm thickness spacer

14. between the reader itself and the phonic wheel.

Block with two 4x10 screws and Z5 knurled

washers, then remove the thickness spacer.

Before reassembling the cylinder, check (on the

15. machine) the encoder is working.

Replace the layer of Loctite 510 (or equivalent)

16. on the cylinder area.

Reassemble the cylinder and follow steps 7-1

17.

(i.e. in reverse order) to completely reassemble

the spindle.

18. Carry out the sensor calibration procedure.

5801H0056 ______________________________________________________________ 154/183