- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- Component Manuals

- HSD Spindle Instructions for Use.pdf

- Page 127 of 183

HSD

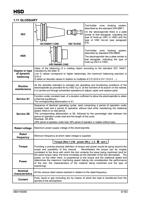

DO NOT DIRECT JETS OF COMPRESSED AIR INTO THE SPINDLE SHAFT WHEN

THE TOOL-HOLDER CONE IS ABSENT (figure below).

NO!

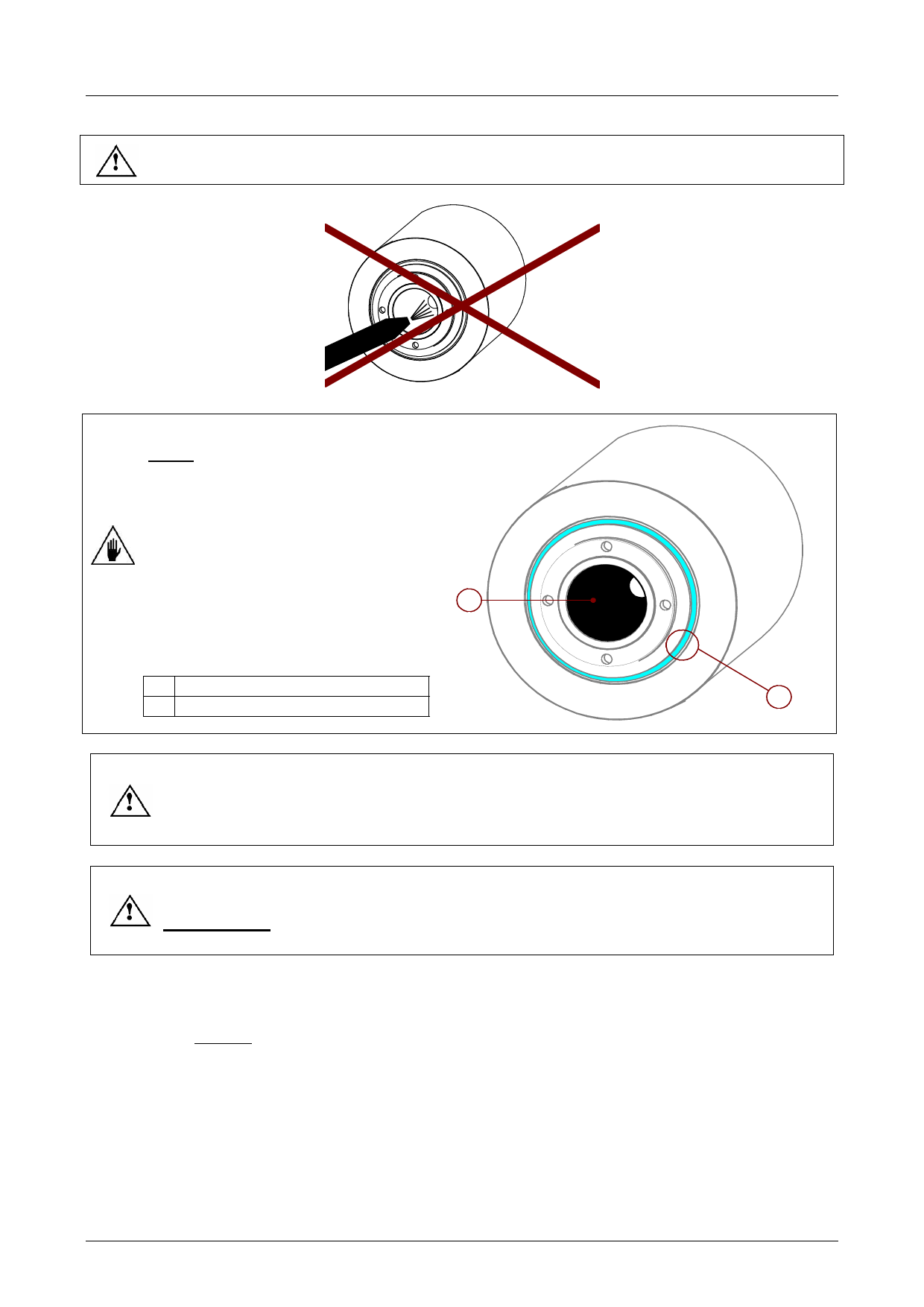

Never point jets into the

pressurised seal labyrinth area, as

the infiltrations damage the inside

of the electrospindle.

Do not point jets inside the

electrospindle when the tool-holder

is not attached, as the coupling

surface with the tool-holder may

1

get dirty or machining operation

waste may enter the electrospindle.

1 Coupling surface.

2 Labyrinth seal.

2

IMPERFECT CLEANING PREVENTS THE CORRECT POSITIONING OF THE

TOOL-HOLDER, WITH SERIOUS CONSEQUENCES FOR THE SAFETY OF THE

OPERATOR, THE WEAR AND TEAR OF THE ELECTROSPINDLE AND TOOL-

HOLDER, THE PRECISION AND EFFICIENCY OF THE MACHINING OPERATION.

TO CLEAN THE SURFACES HIGHLIGHTED FROM Figure7 1. TO Figure7 4.,

USE CLEAN, SOFT CLOTHS;

NEVER USE ABRASIVE INSTRUMENTS SUCH AS WIRE WOOL, METAL

SCRAPERS, EMERY CLOTH, ACIDS OR OTHER AGGRESSIVE MEDIA.

7.1.2 Purging the filters of the pneumatic circuit

Frequency: DAILY

At the end of the work shift, discharge the compressed air circuit to allow the automatic purging of

the filters that protect the HSD product (see section 4.4)

5801H0056 ______________________________________________________________ 127/183