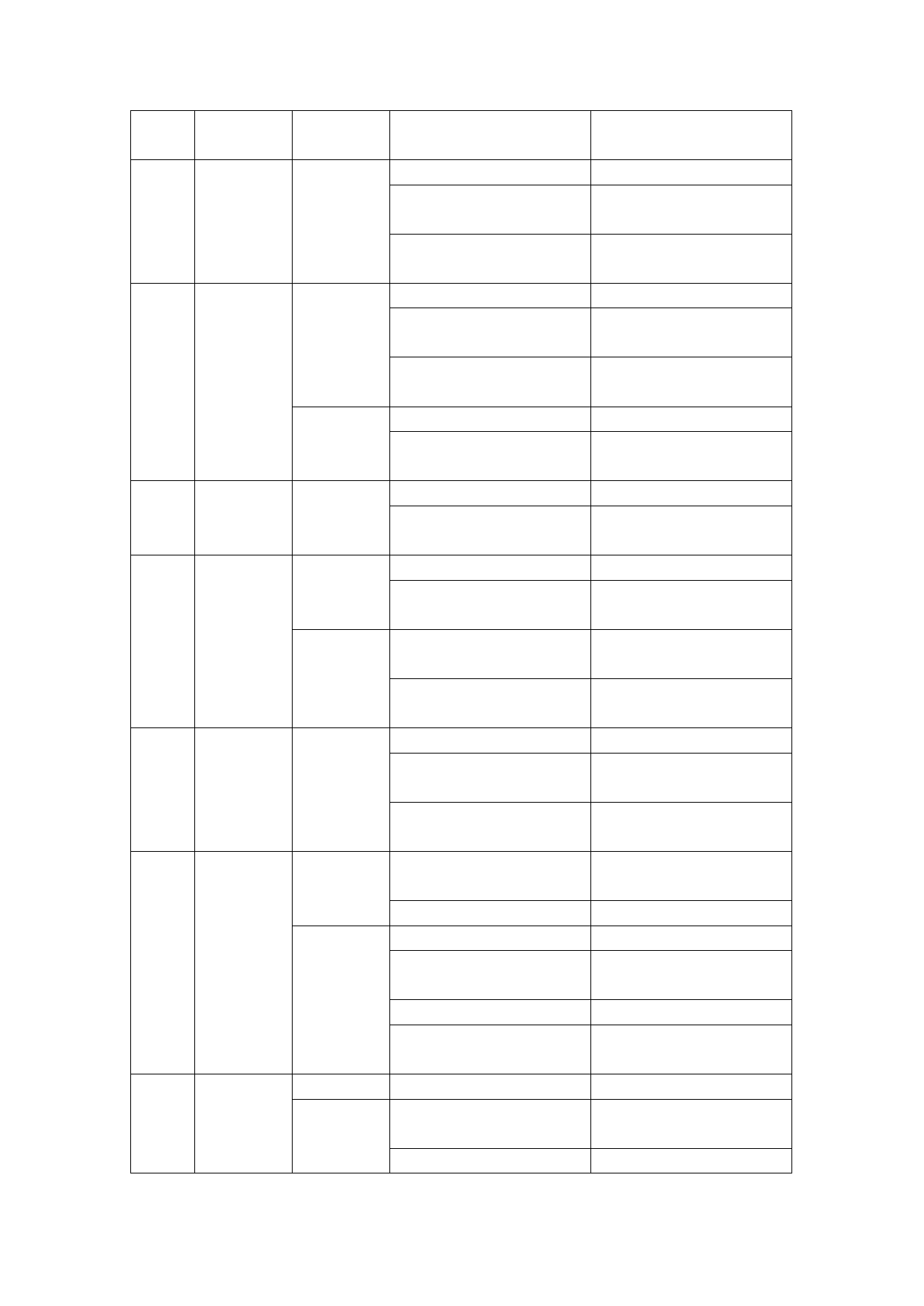

7

Disable

Power on

● Check parameters and wires

★PA20, CW and CWW wires

abnormal

8

Position

deviation

In operation

● Motor stalling

● Command frequency abnormal

★Check the load.

★ Reduce the speed of the upper

counter overflow

computer.

●Wiring incorrect

★Check the wire and connect the

shielding layer.

9

Encoder failure Power on

●Encoder wiring incorrect

●Encoder damaged

★ Connect the wire correctly.

★ The encoder is a fragile article and

should be replaced.

● Encoder 5V voltage low

★Shorten the wire or replace the

driver.

In operation

● CN2 connector contact poor

●Hidden trouble exists in cable faulty

★Tighten the CN2 connector.

★Replace the cable.

10

Software failure Power on

welding.

●software download mismatching

●The chip of the circuit board failure

★Update the software.

★Find out the interference and replace

the driver.

11

IPM module Power on

●Circuit board failure

★Replace the servo driver.

failure

● Short circuit between U, V and W of ★ Check the wire and replace the

In operation

the motor

● Motor failure

motor.

★Check the wire and replace the

motor.

● Poor connection to power supply

★ Check the wire and prevent

interference.

12

Overcurrent

Power on or in

operation

● Motor damaged

●Short circuit between U, V and W

★Replace the motor.

★Check the wire and replace the servo

driver.

●Overload

★Replace the current motor by a

high-power motor.

13

Overload

Power on

● The motor is damaged and water has ★Replace the motor.

In operation

entered the motor.

●Circuit board failure

● Mechanical load too great

●Mechanical transmission not freely

★Replace the servo driver.

★Reduce the load.

★Check Mechanical transmission

parts.

●Short circuit between U, V and W

●The band-type brake fails to loosen.

★Check the cable.

★Ensure that power supply for the

band-type brake is stable.

14

Brake failure

Power on

In operation

●Circuit board failure

●Braking resistor damaged

★Replace the servo.

★Check the wire of the braking

resistor.

●Braking capacity insufficient

★

Prolong

the

68