- You are here:

- AM.CO.ZA Buythis CNC Utilities Homepage

- G5 Material Print testing Case studies with printing parameters.pdf

- Page 23 of 24

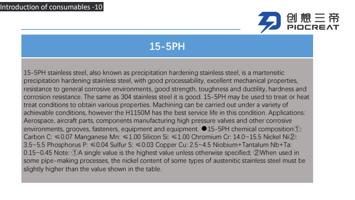

Introduction of consumables -10

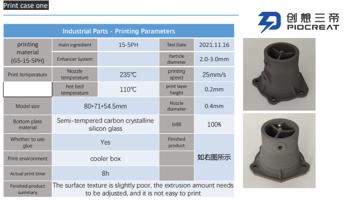

15-5PH

15-5PH stainless steel, also known as precipitation hardening stainless steel, is a martensitic

precipitation hardening stainless steel, with good processability, excellent mechanical properties,

resistance to general corrosive environments, good strength, toughness and ductility, hardness and

corrosion resistance. The same as 304 stainless steel it is good. 15-5PH may be used to treat or heat

treat conditions to obtain various properties. Machining can be carried out under a variety of

achievable conditions, however the H1150M has the best service life in this condition. Applications:

Aerospace, aircraft parts, components manufacturing high pressure valves and other corrosive

environments, grooves, fasteners, equipment and equipment. ●15-5PH chemical composition①:

Carbon C: ≤0.07 Manganese Mn: ≤1.00 Silicon Si: ≤1.00 Chromium Cr: 14.0~15.5 Nickel Ni②:

3.5~5.5 Phosphorus P: ≤0.04 Sulfur S: ≤0.03 Copper Cu: 2.5~4.5 Niobium+Tantalum Nb+Ta:

0.15~0.45 Note: ①A single value is the highest value unless otherwise specified; ②When used in

some pipe-making processes, the nickel content of some types of austenitic stainless steel must be

slightly higher than the value shown in the table.