FastCUT® OPTIMIZER

FOR SAWS, SHEARS & HAND CUTTING

Ideal for Flat Glass, Metal, Wood, Laminates ..

HIGHLIGHTS:

• PRINTED CUTTING LISTS

AND GRAPHIC LAYOUT

• INBUILT NESTING ENGINE

FOR BEST LAYOUT

• ESTIMATES MATERIAL &

PROCESSING COSTS

• AVAILABLE FOR LENGTH,

RECTANGLES AND CUT TO

LENGTH

• AUTOMATIC & EASY—

DESIGNED FOR TRADES

• MULTI-LANGUAGE SUPPORT

• MICROSOFT WINDOWS

Nuts and Bolts:

Customized versions available

for Metal, Glass & Wood

Nests across multiple sheet sizes

& uses remnant first

Handles up to 2001 individual

parts & 51 individual stock items

Quick View / Print of Cutting

Lists and Costings

Kerf and grain allowance (where

appropriate)

Cut & Paste into Microsoft Excel

(if required)

OPTIONAL Label Module for part

identification & Quality Control

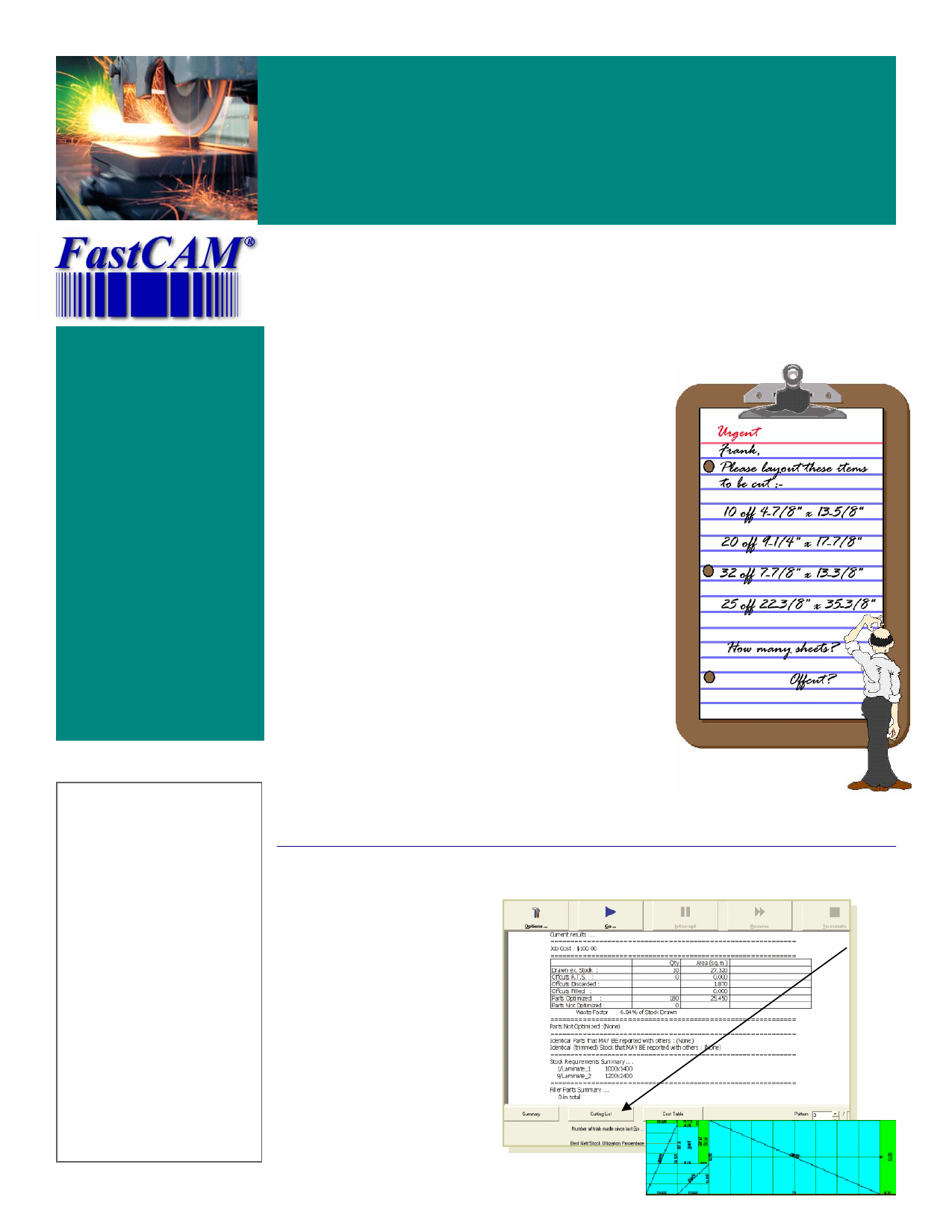

MORE PARTS & LESS WASTE - RECTANGLES AND LENGTHS

FastCUT® adds real value to

any business cutting flat

rectangles or lengths of

materials on a routine basis.

FastCUT® is fast & easy. Just

list the parts and stock to

create a simple optimized job

estimate, dimensioned

pattern, cutting list and job

summary.

FastCUT® is being used

successfully around the

world in industries covering

metals processing, sheet-

metal, flat glass, stone

masonry, timber & related

industries.

FastCUT® users report many

advantages¹ :

• Much better stock yield

overall with some jobs

dramatic

• Dramatically less time on

estimating

• Useful to assess the Cutting

Loss on big jobs quickly

• Easy to find out the best

size stock to use for the job

and try “what if’s”

• Huge time saver having the

ability to print cut lists

• Speeds Cut to Size

Requests

FastCUT® customers cut flat

material using both manual

and automatic cutting

processes.

• Improves stock ordering

• Easy to match stock used at

quote with actual stock cut.

¹FastCUT® has proven to be a simple and affordable solution for many companies — Testimonials are available.

INBUILT NESTING ENGINE FOR OPTIMIZED LAYOUTS & CUTTING LISTS

Nesting is automatic and fast

so you use the best sizes, less

material and you know what

stock to order.

The nesting engine runs

through millions of scenarios

and also considers the various

rotations of the parts. You can

choose to optimize on cost or

material. You can also choose

simple nesting for speed or

exhaustive nesting for critical

or larger jobs.

Print a cutting

list and layout

to give to

production at

time of order