- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- Italy HSD Spindle

- Y580100001_AT-MT_en_Rev 04.pdf

- Page 13 of 22

______ HSD __________________________________________________________________________________

6.4 MECHANICAL CONNECTIONS

6.4.1 ELECTRO-SPINDLE SUPPORT PLANE

i

THE SUPPORTING PLANE ON WHICH THE ELECTRO-SPINDLE IS INSTALLED MUST

HAVE A PLANARITY RATING EQUAL TO OR BETTER THAN 0.025MM

6.4.2 FIXING THE ELECTRO-SPINDLE

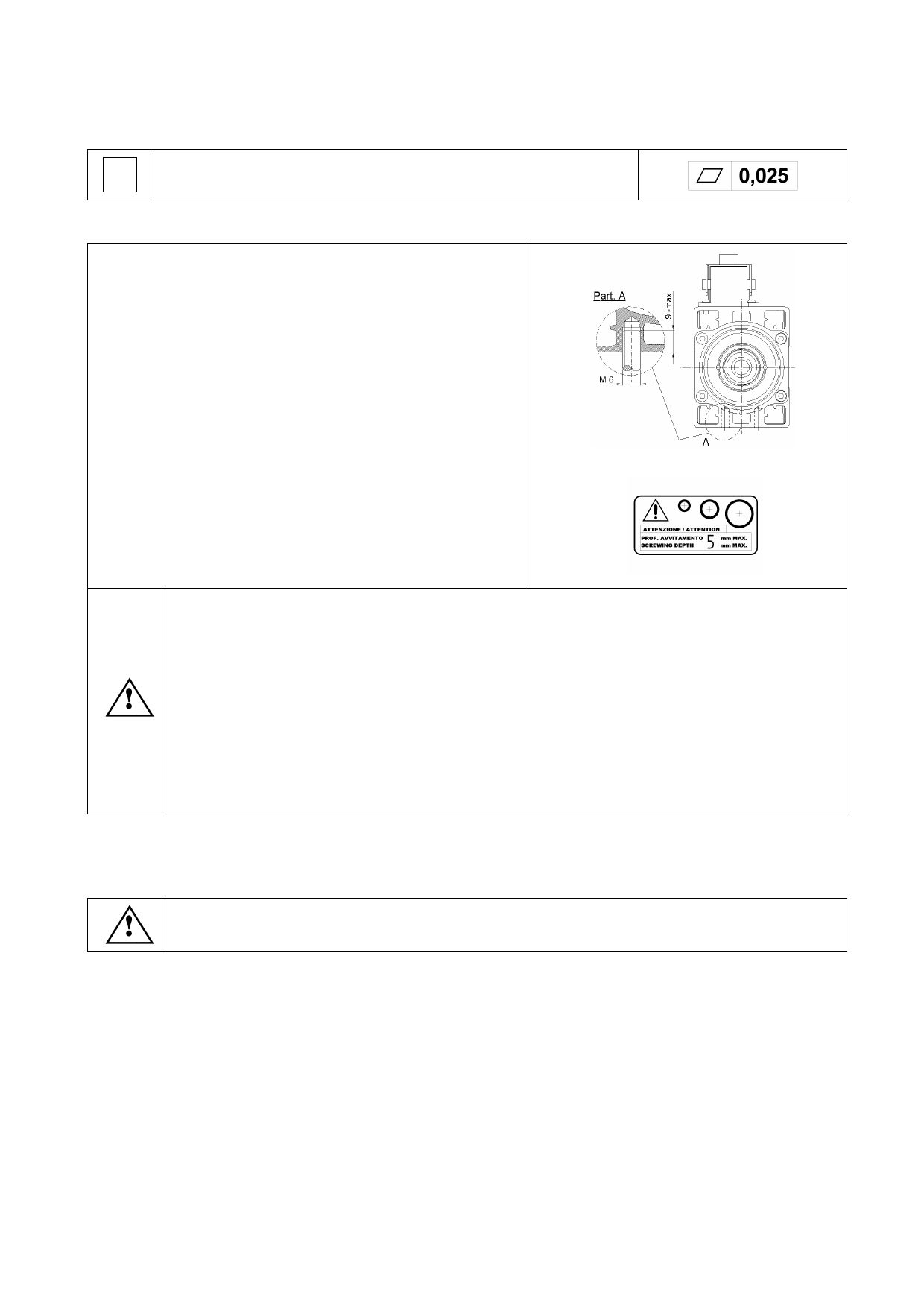

The electro-spindle must be fixed to the machine carriage or support

by means of bolts. Maximum penetration of bolts from the support

plate is shown in the overall dimension drawings. (See data sheet)

Figure 6.1 alongside shows an example of electro-spindle fixing

holes with permitted bolt penetration dimensions.

The fixing holes on some electro-spindles are through holes,

because of the limited thickness of the body. To prevent dust and dirt

from entering the unit, these holes are closed off with plastic plugs.

These must be removed before the unit can be installed in the

machine. These units are also fitted with a plate informing the

installer of the maximum allowable bolt penetration depth. (See the

example in Figure 6.2)

Figure 6.1

Figure 6.2

EXCESSIVE BOLT PENETRATION CAN CAUSE DEFORMATION OF THE ELECTRO-SPINDLE’S BODY, AND MECHANICAL OR

ELECTRICAL DAMAGE THAT CAN LEAD TO SPINDLE MALFUNCTIONING.

FIXING BOLTS MUST BE TIGHTENED WITH A TORQUE WRENCH.

IT IS VERY IMPORTANT TO RESPECT THE TIGHTENING TORQUE SPECIFICATION, SPECIALLY WHEN INSTALLING

ELECTRO-SPINDLES ON WHICH ONLY A LIMITED LENGTH OF BOLT CAN BE SCREWED INTO THE FIXING HOLES. FIXING

BOLT TIGHTENING TORQUE MUST BE DETERMINED BY THE CUSTOMER ON THE BASIS OF ELECTRO-SPINDLE TESTS IN

THE MACHINE IN WHICH IT IS TO BE INSTALLED.

EFFECTIVE TIGHTENING TORQUE CAN VARY SIGNIFICANTLY UNDER THE EFFECT OF FRICTION, THE PRESENCE OF

GREASE, AND THE SPEED AT WHICH TIGHTENING IS DONE.

TIGHTENING TORQUE MUST BE DETERMINED TO SUIT THE APPLICATION TO WHICH THE ELECTRO-SPINDLE IS TO BE

PUT.

WHILE FIXING THE UNIT IN PLACE, TAKE CARE NOT TO BLOCK OFF THE COOLING FAN GRILL OR OTHERWISE IMPEDE

THE FLOW OF COOLING AIR. ALWAYS LEAVE THE MINIMUM GAP AROUND THE UNIT SPECIFIED IN THE OVERALL

DIMENSION DRAWINGS. (SEE DATA SHEET.)

6.5 ELECTRICAL CONNECTIONS

(see data sheet)

ALWAYS USE POWER CABLE OF ADEQUATE CROSS SECTION FOR THE RATED CURRENT OF THE ELECTRIC MOTOR.

(SEE DATA SHEET)

NEVER FIT OR REMOVE CONNECTORS WITH THE ELECTRO-SPINDLE POWERED ON.

Y580100001 rev.03 ____________________________________________________________________ 13