Socket No. 7

5

6

4

3

2

1

SD+ and SD- are data output signals; E+ and E- are battery leads.

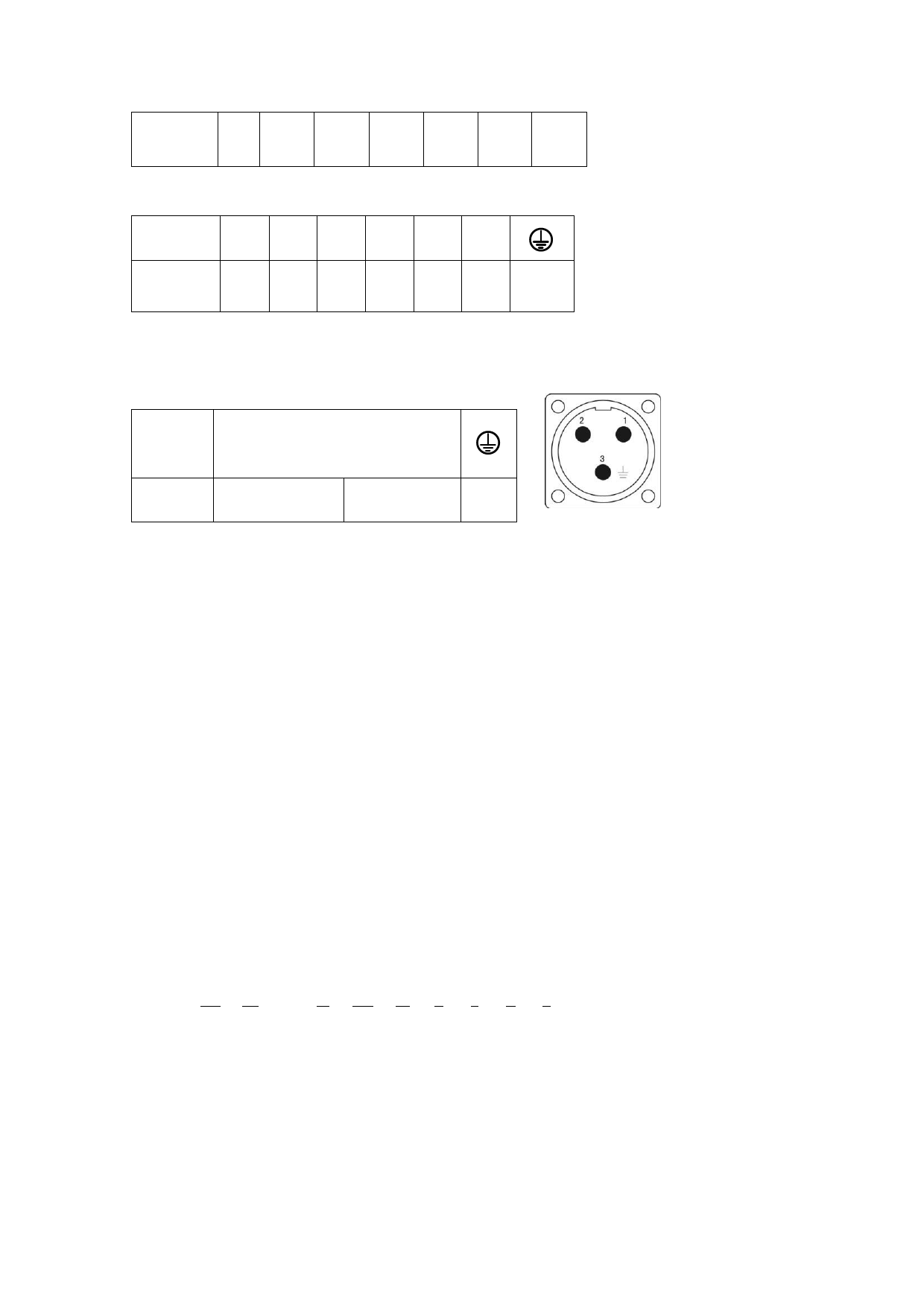

●Socket (with 7 prongs) for rotatable transformer (R)

Signal

R1 R2 S1 S3 S2 S4

Socket No. 2

3

4

5

6

7

1

R1-R2 are primary signals, S1-S3 and S2-S4 are secondary signals.

III. Socket for Safe Brake (Band-type Brake):

VDC(direct current power supply)

Power supply without requirements on polarity access.

Socket No.

1

2

3

Safe brake parameters allocated for Seat 110

Working pressure: 24VDC (-15%-+10%), working current: ≤0.6A, braking torque: ≥8Nm

Safe brake parameters allocated for Seat 130

Working pressure: 24VDC (-15%-+10%), working current: ≤0.6A, braking torque: ≥12Nm

Safe brake parameters allocated for Seat 150

Working pressure: 100VDC (-15%-+10%), working current: ≤0.4A, braking torque: ≥30Nm

9.2 Description of Model Selection of Servo Motors

● Parameter characteristics

Seat (mm): 80, 110, 130, 150

Rated torque (Nm): 1.3-27

Rated speed (rpm): 1500, 2000, 2500, 3000

Rated power (kW): 0.4-5.5

Standard matching feedback elements:

incremental encoder (2500C/T)

Safe brake: matching

Insulation level: B

Protection level: closed self-cooling IP65

Number of pole-pairs: 4

Ambient temperature: 0-550C

Installment mode: flange plate

Ambient humidity: < 90% (without condensation)

Excitation mode: permanent magnet

Working voltage of adaptive driver (VAC): 220

●Description of type codes of LB series servo motors:

110 ST – M 020 30 L F B Z

(1) (2)

(3) (4) (5) (6) (7) (8) (9)

(1) Seat No.

(2) AC Permanent magnet synchronous servo motor

(3) Type of feedback element: photoelectric encoder

(4) Rated torque: three figures ×0.1Nm

(5) Rated speed: two figures ×100rpm

(6) Working voltage of the driver (VAC): 220

77