- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- EasyRoute-CNC-Router

- Component Manuals

- 华大系列说明书116版(英文)修改后.pdf

- Page 68 of 100

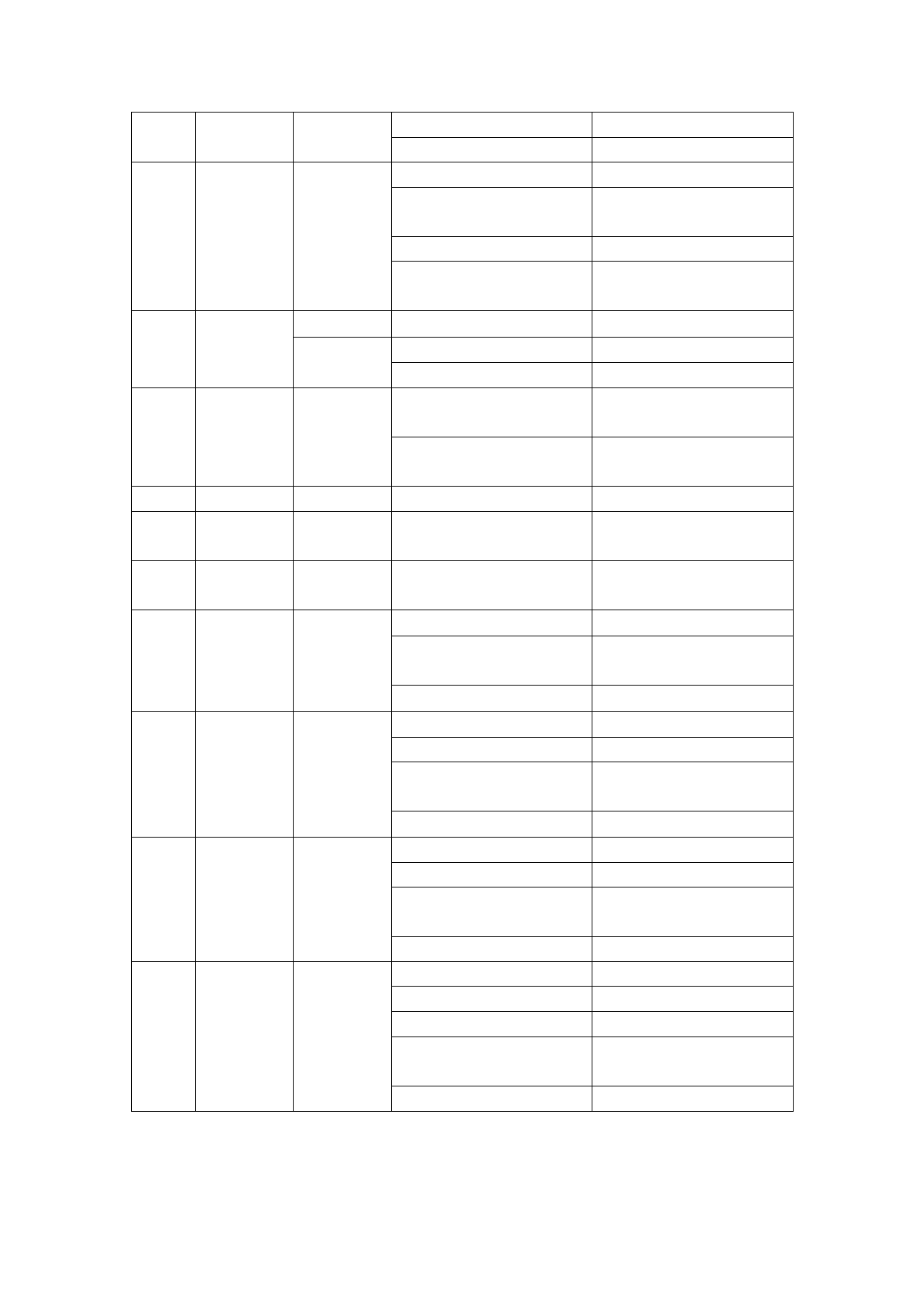

acceleration/deceleration time.

●Mechanical inertia too great

★Reduce the mechanical inertia.

15

Encoder count In operation

● Encoder damaged

★Replace the encoder.

incorrect

●Encoder wiring incorrect

★Check the wiring and replace the

encoder.

● Encoder power supply unstable

★5V voltage should be stable.

●The number of encoder wires ★Adjust the number of wires

incorrect

corresponding to the parameter.

16

Motor thermal Power on

● Servo parameter incorrect

★ Restore the factory value.

overload

In operation

●Mechanical transmission not freely

★Add lubricant and reduce load.

●Overload time long

★Reduce load; start/stop are smooth.

17

Speed response In operation

● Long-time error too great

★Adjust parameter position

failure

feed-forward.

●Start/start time too short

★Adjust the acceleration/deceleration

time.

19

Hot reset

In operation

● Power supply unstable

★ Check power supply and wiring.

20

ROM alarm

In operation

● Parameter storage alarm

★Restore the parameter and replace

the servo.

23

Electric leakage In operation

failure

●Short circuit or motor leakage

★Check the wiring or replace the

motor.

29

Torque

In operation

● Set torque exceeded

★Check Parameters PA30 and PA31.

insufficient

● Check the model selection of the ★Readapt the motor again.

motor.

● Mechanical overload

★ Disconnect the load and try again.

30

Encoder Z-pulse In operation

●Z-pulse doesn’t exit.

★Replace the encoder.

loss

●Cable weld line incorrect

★Check the weld line.

●5V Voltage unstable

★Shorten the wire and reduce

attenuation.

●Poor shielding leads to interference. ★Well ground the shielding layer.

31

Encoder UVW In operation

●UVW pulse doesn’t exit.

★Replace the encoder.

signal incorrect

●Cable weld line incorrect

★Check the weld line.

●5V Voltage unstable

★Shorten the wire and reduce

attenuation.

●Poor shielding leads to interference. ★Well ground the shielding layer.

32

Encoder UVW In operation

●UVW pulse doesn’t exit.

★Replace the encoder.

signal angle

●Encoder model incorrect

★Check the encoder model.

misplacement

●Weld line misplacement

★Check the weld line.

●5V Voltage unstable

★Shorten the wire and reduce

attenuation.

●Poor shielding leads to interference. ★Well ground the shielding layer.

● Where the Alm red lamp is on and the Alarm ―Err--xx‖ in the digital tube flashes, the alarm is a driver alarm. Cut

off the power in time and find out the cause of the alarm.

68