LFS-PM-T43 operating manual

XXXIV

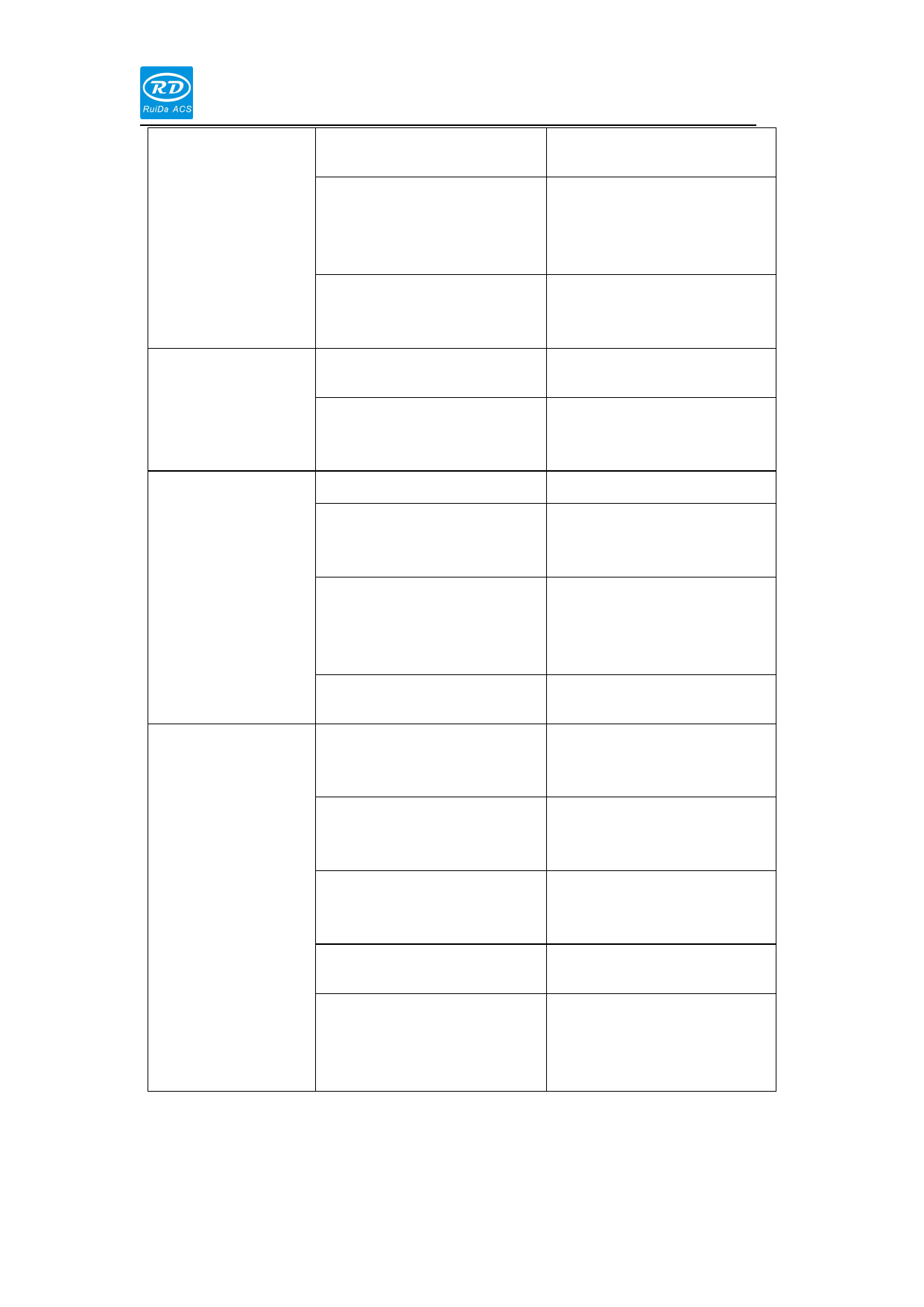

head is too far away from the laser head close to the metal

metal sheet.

sheet.

Before calibration, check the

During the calibration, up limit positon of the laser head. Move

or down limit triggered.

the laser head away from the

limit

There is no motion and cause a

time out

Check the parameters of the

servo drive and can run a jog

motion

“write para” can not

write the parameters

into the distance

controller

The laser head is in the running

status.

wrong connection between the

displayer and the distance

controller.

Stop motion and set laser head

to be standby status

Check the wire and the

interface

no calibration for a long time

Calibration again

There is big erro

between the actual

height and the

referenced height

Laser head shaking

during tracing

Has changed some parts of the

sensor but do not do the

calibration.

Some laser beam is located on

the capacity sensor or the lens

is dirty and make the sensor ‘s

temporature increasing.

Auxiliary gas has caused the

capacity changing

Shield of the amplifier do not

have good conduction with the

machine

PID parameter is not normal

Before start a normal cutting.

Calibration is not done or the

calibration result is not so good.

Servo stiffness is too big

Calibration again

Check the lens is clean and the

position of the laser beam

Check the cleaness and the

humidity of the auxiliary gas

Chenck the EARTH wire is

connected well

Decrease the P parameter and

decrese the responsibility of the

distance controller

Calibration again

Decrease the stiffness

Servo electrical interference

Check the shield of servo drive

is connect to the EARTH.

Connect

Thank you for your selection of our production!

All the copyright of this manual is owned by Ruida technology. Any person or company can