Page 106 of 107

RDC6563F Standalone Fiber Cutting Control System User Manual V2.0

105

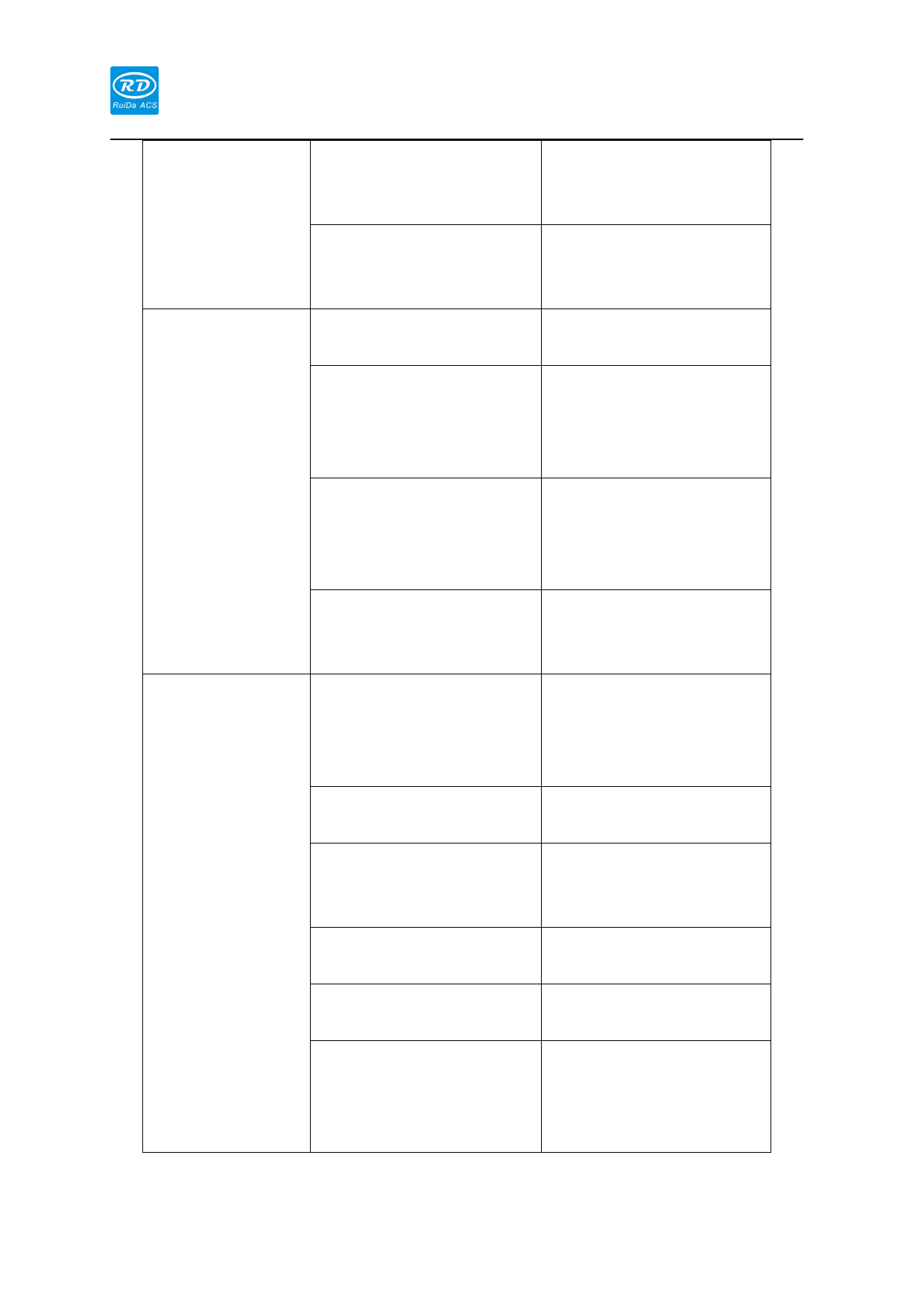

Trigger upper and lower limit In [capacitor calibration],

switches during [capacitor manually move the cutting

calibration]

head off the limit switch 。

The motor does not actually

rotate and causes a timeout

to exit.

First ensure that the motor

can move normally

No capacitor calibration for a

Re-capacitor calibration

long time

No recalibration of the

The height following

is significantly

different from the

actual height

capacitor after replacing the

Re-capacitor calibration

capacitor sensor and other

accessories

Part of the laser is scattered

onto the capacitive sensor,

causing

the

nozzle

temperature to rising.

Please check if the lens is

clean and the laser is not

biased.

Blowing causes

change in the

capacitance value

a large

detected

Please check if the gas is dry

and pure

Poor contact of the amplifier

shell (or metal plate) with the

machine

Ensure that the amplifier

shell (or metal plate) is in

good contact with the

machine

Filter coefficient setting is too

Reduce the filter coefficient

large

No capacitor calibration or

When following, calibration results are not Re-capacitor calibration

there is a serious good

jitter

Plate shake caused cutting Appropriate increase of jitter

shake when blowing

filtering time

Servo drive rigidity setting is

Reduce servo stiffness

too large

Connect the height adjuster

Large machine interference

PGND to the machine shell

while connecting the shell to

the earth

SHENZHEN RUIDA TECHNOLOGY CO., LTD