Page 104 of 107

RDC6563F Standalone Fiber Cutting Control System User Manual V2.0

103

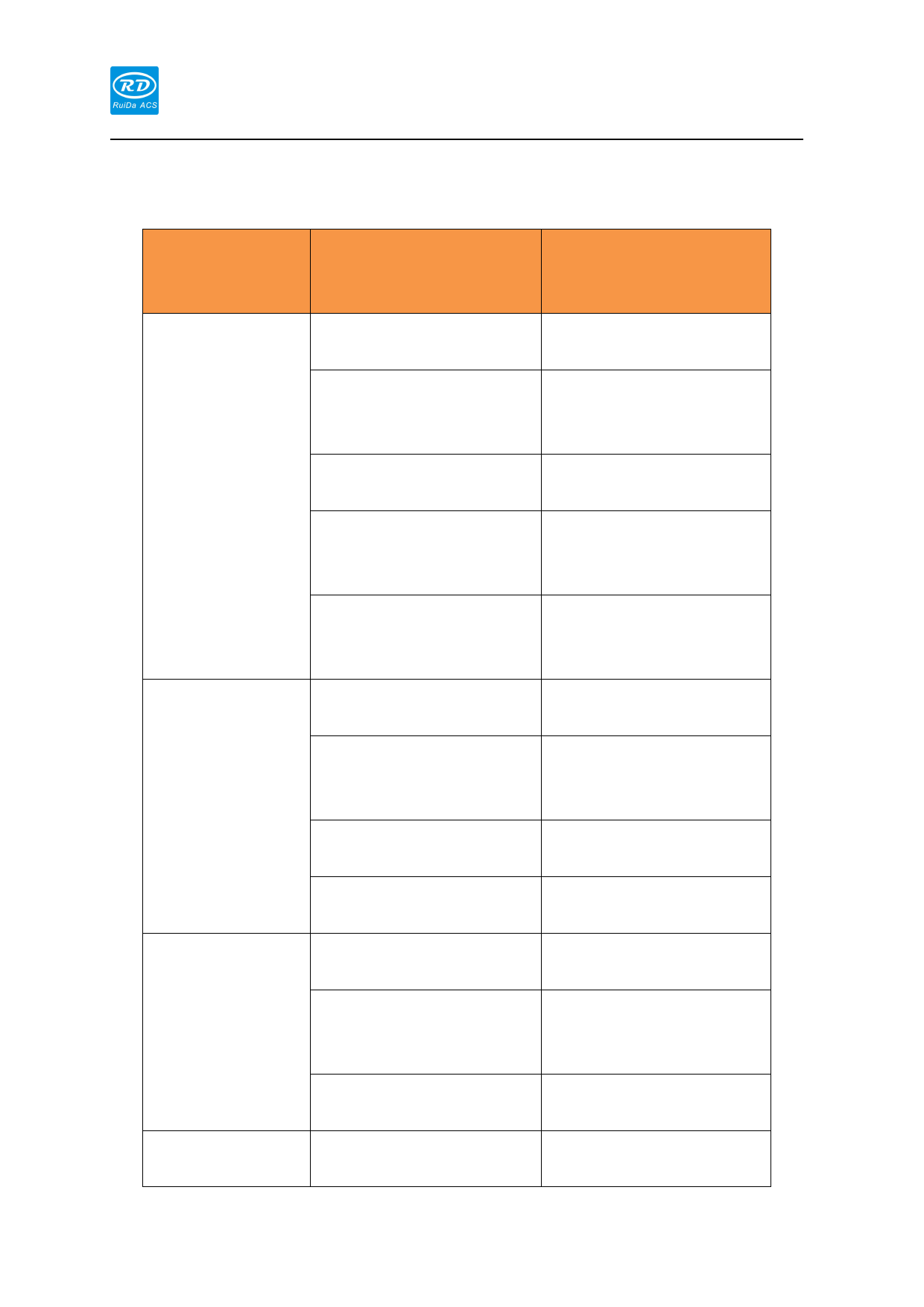

9.1 Common Troubleshooting Methods

Common

Troubleshooting

phenomenon

Manually move by Z

axis on the panel,

the cutting head

does not move

XY Axis manual

does not move

Communication

failed via USB

connection

Communication fails

via Ethernet

Reason

The servo drive is not wired

correctly

Servo drive parameter

settings are incorrect

Servo drive does not support

speed control mode

An alarm occurs on the Z axis

of the main board, causing to

stop.

The panel is not connected

properly with the mainboard.

The servo drive is not wired

correctly

Servo drive parameter

settings are incorrect

The polarity of the limit is set

incorrectly, causing to stop.

Servo drive generates an

alarm

USB driver not installed

properly

The mainboard and computer

are not connected to the USB

cable or the cable is faulty.

Not set to USB connection

properly

Network IP settings are

incorrect

Solution

Refer to the user manual for

proper wiring.

Set the parameters correctly

according to the servo drive

manual

Please select a drive that

supports speed control mode

Eliminate alarm faults

according to alarm prompts

on the panel interface

1、Check if the panel cable

2 、 Z-axis movement can be

controlled by

Refer to the user manual for

proper wiring.

Set the parameters correctly

according to the servo drive

manual

Correctly set the limit polarity

Please restart the servo to

cancel the alarm.

Please install the USB driver

correctly

Please replace the USB

cable to ensure that the USB

connection is normal.

Please set the connection

method to USB connection

Please set the mainboard IP

address correctly.

SHENZHEN RUIDA TECHNOLOGY CO., LTD