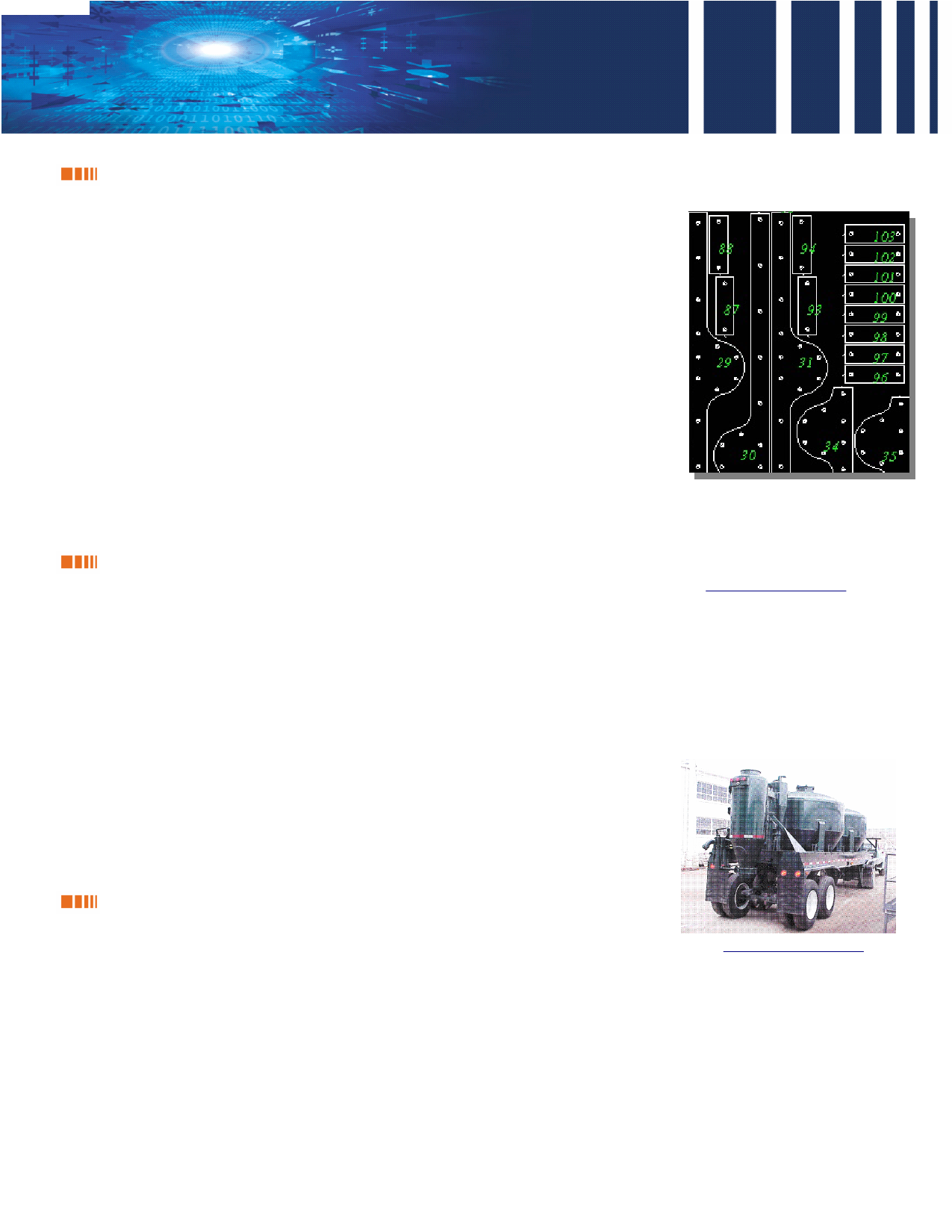

FAST & EASY FULLY AUTOMATIC NESTING WITH MANUAL OVERRIDE

FastCAM® Standard &

Professional Editions include •

the FastNEST® nesting mod- •

ule to optimize both the

material usage and the •

sequence of cutting. Parts •

can be nested automatically

or manually placed for •

maximum productivity.

Nest a variety of file formats •

with support for all secondary •

processes like marking.

Multiple primary process are •

also

mixed

supported including

Oxy-fuel, Plasma, even

•

bevel cutting.

Fast ‘One click’ nesting

TRUE SHAPE

Simple & Complex Nests

Auto Nesting ‘Pause’

Single and auto pair arrays

for same parts

Bulk part input

Multi Torch

Multi plate nesting

Auto Placement of parts to

preset distance.

• Auto plate trim

• ‘Jostle’ to pack nests

• Post nest optimization inc

Bridging, Tabbing & Stitch

Cutting

• Hole avoidance and rapid

travel minimization

• Dynamic part rotation

• Move pierce points with

simple ‘point & click’.

• Nests all NC languages,

CAM, DXF, IGES

Nest like an expert in minutes!

CHOOSE FROM 3 EDITIONS TO SUIT YOUR BUSINESS NEEDS

FastCAM® NC

FastCAM® Standard

FastCAM® Professional

Drawing, No Nesting, Create Drawing with True Shape Semi

parts and output the NC code. Automatic Nesting. Single Plate.

Includes FastCAM® Drawing Feature-rich but manual.

Editor and FastPLOT™, DXF input Includes FastCAM® Drawing

with CAD smart tools.

Editor, FastPLOT™ & FastNEST®

Ideal for single

cutting. Draw &

& repeat part

Path manually.

Interactive (semi-automatic) and

CAD smart tools.

Simplest system. Lowest Cost. Suited to non-critical or non-

Add FastNEST® or FastPATH™

later if and when required.

demanding production levels. Eg.

Repetition cutters, low duty cycle.

Upgrade later if required.

Note: Refer to the FastCAM System Comparison Chart for a more a detailed list.

Full Shape, Full Auto Nesting,

Multi Plate, Multi input, Multi

output. Automatic ‘everything’.

Ability to move pierce function

before and after nesting.

Includes FastCAM® Drawing

Editor, FastPLOT™, FastPATH™,

FastNEST® Fully Automatic, (bulk)

CAD smart tools.

Complete NC programming

system. Tackle any job with

precision & speed.

Specify your

individual machine

controller at time

of order. See over.

OFFERING SOLID SERVICE, MAINTENANCE & SUPPORT

All Fast CAM® Systems Annual Service Maintenance Fas t CAM® c om es with

Include 30 days FREE Agreements are also avail- Excellent Electronic Tutorials

technical support* to ensure able.

and Self-help tools however

that you are up and running

quickly.

SMA’s give you Priority

Support, Upgrades and

On-site Training is available if

required.

Free self-help is available via M e m b e r D i s c o u n t Courses can be tailored to

our web site and pay per Entitlements.

meet your needs. No previous

incident support is available

as and when required.

Contact FastCAM for current

pricing.

PC skills are required.

Contact your local FastCAM

Office or reseller for pricing.

“After 10 days

with FastCAM®

I built my first

tank truck. Now

it’s our livelihood”

Ray Castlebury

Castlebrook Welding

& Fabricating

* Technical support by phone, fax, email. Excludes on-site, installation and O/S support.