Chapter 7 Parameter Setting

Pierce Up Time: Time for the torch to lift up during perforating. The difference

between Torch Up Time and Pierce Up Time is that: Torch Up Time means the time

that the torch needs to lift up when it needs to move to another place after the current

cutting is over; while the Pierce Up Time means the time that the torch needs to lift

up after preheating in the fixed cycle of perforation.

Pierce Down Time: Time for the torch to put down in the perforation. The difference

between Torch Down Time and Pierce Down Time is that: Torch Down Time

means the time that the torch needs to put down before preheating; while the Pierce

Down Time means the time that the torch needs to put down after finishing Torch Up

Time and opening cutting oxygen in the fixed cycle of perforation.

THC Enable: According to the user device configuration, choose whether or not to

use high adjustment box.

Hold Preheat:If this parameter is set as “yes”, in the process of cutting, before

complete cutting (before M02 code has occurred), Low Heat IO port is on the open

status all the time. If set the parameter as “no”, in the process of cutting, M08 or M02

code has occurred, it will close Low Heat IO port.

Edge Cutting Enable:press 【←】 or 【→】 to use or not use edge cutting. When

use edge cutting, the cutting system will automatically stop whenever M07 code has

occurred. When it stops, user can manual operate to move the torch to the edge of

steel panel, then press start button, the system will notify:

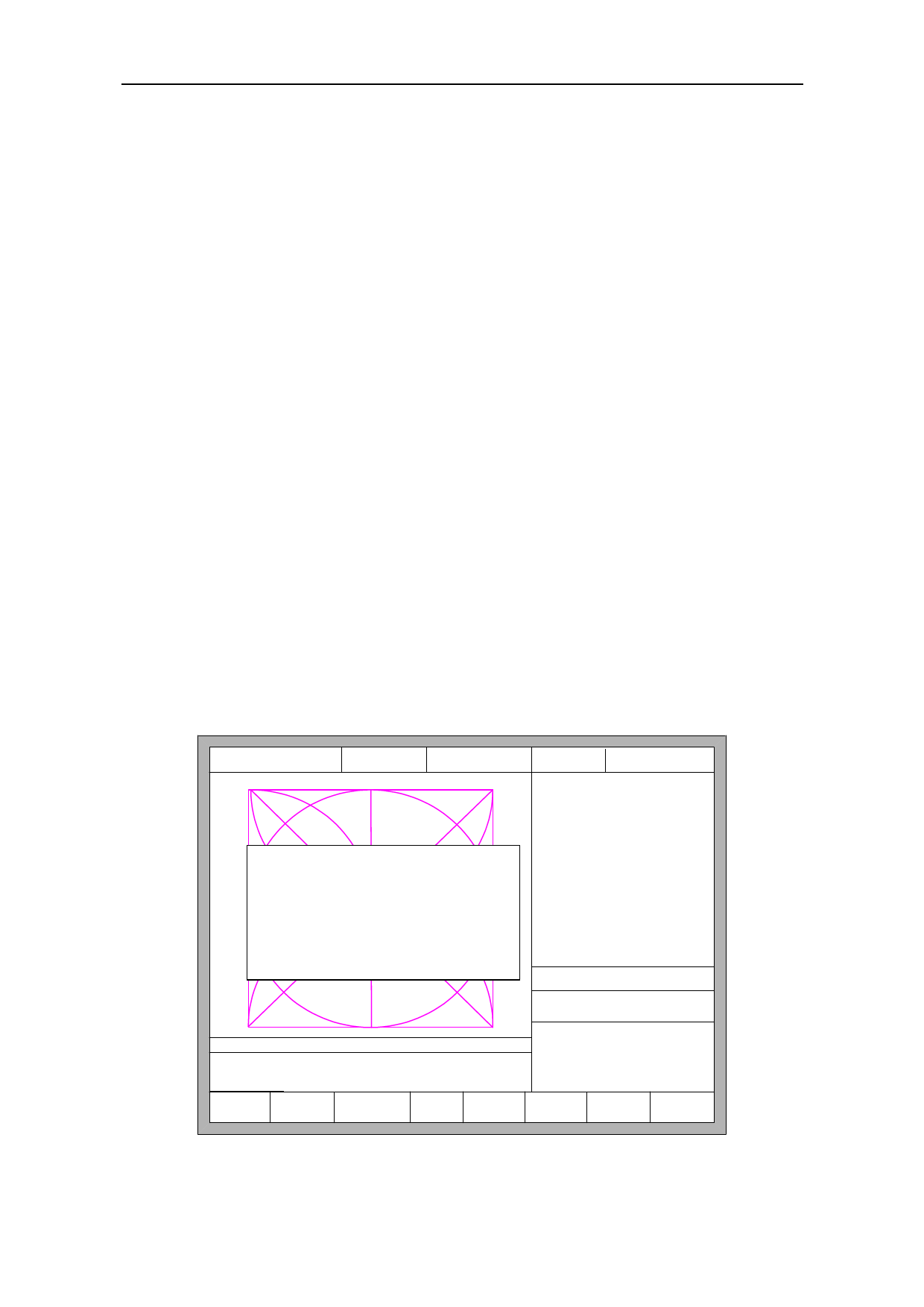

FLSK F2200T

Version 3.3.71.1

Speed:

00000

File:

SHAPE_43.TXT

Status:

Stop

Current Line/Hole:

00000/00000

[G]Cutting return

[X]Offset cutting

[Y]only return

●Ignition

s

●LowHeat

s

●HighPreheat

s

●Pierce1

s

●Pierce2

s

●Pierce3

s

●TorchUp

s

●TorchDn

s

●THC En

●Blow

s

CutSpeed 【X】1000.00 Kerf【N】1.20

ManualSpeed【Y】3000.00 Angle 0.00

Manual 【F】 keepMov

StepDis【G】 5.00 Flame Cu 【M】

+X:500.00 -X:0.00 +Y:500.00

1:(TEST PATTERN)

2:G92

-Y:0.00

X:+000000.0

Y:+000000.0

F1 Back

F2 Demo

F4

F5

F6

F7

F8

F3 Frame

Speeddown Speedup PreheatDown PreheatUp JumptoPierce

Fig.7.3 Edge cutting

53