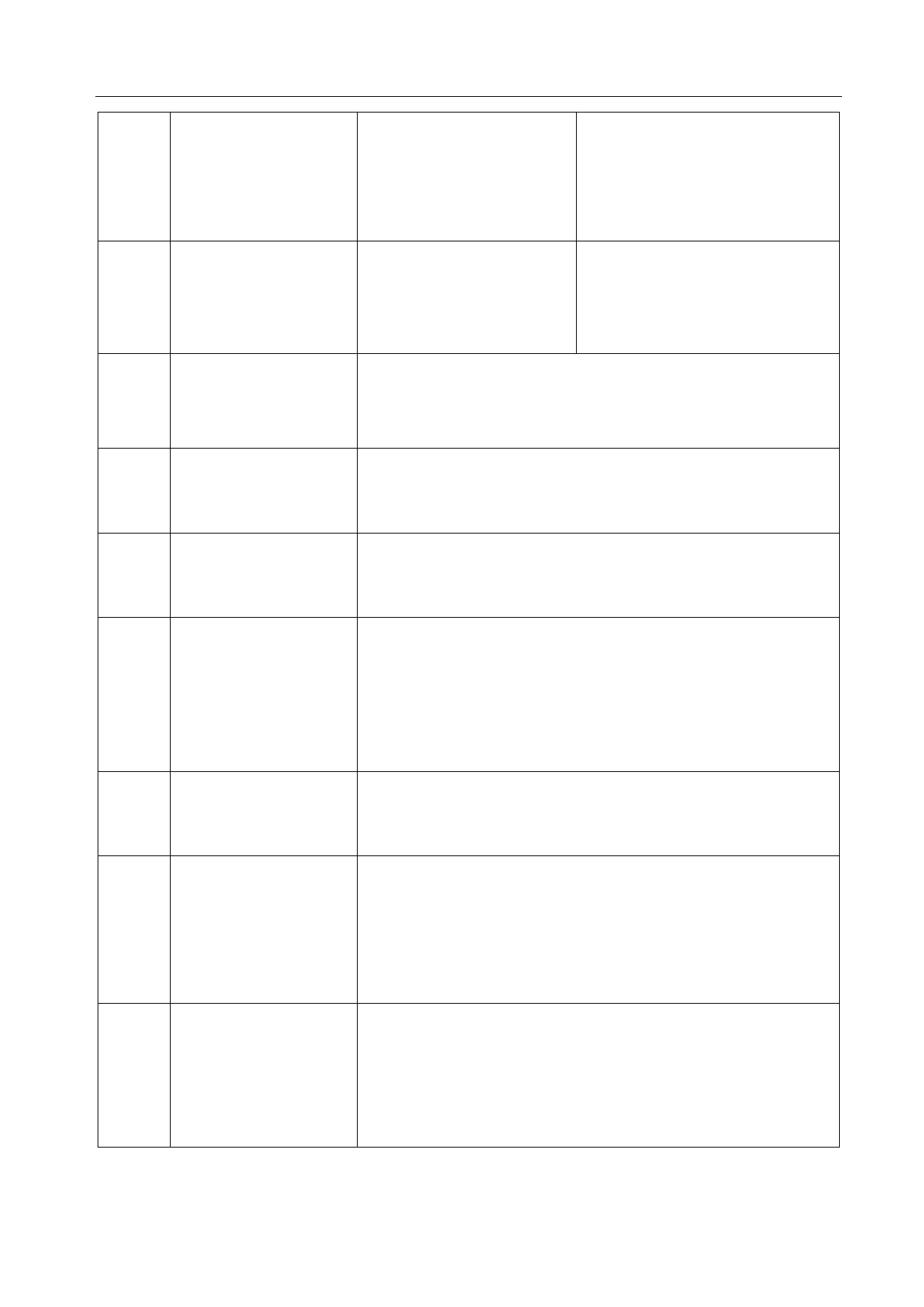

6

The machine start to Setting

time

of 1、increase SET-PIERE time

work before the SET-PIERE is too short 2、adopt the arc feedback signal

accomplishment of

of Plasma itself

arc-beginning

7

Plasma produce arc When we use the Prolong the delay time of CNC

before the IHS

EXARCON signal, the IHS

delay-time of CNC

controlling is too short

8

Cutting torch can not 1、Confirm the working situation of Plasma power

produce arc

2、Check the height of IHS

3、Check the cutting torch fittings

9

Plasma cutting torch 1、Check the connection of working lead

can not transfer to 2、Check the cutting torch fittings

workpiece

10

Cutting torch move Prolong the time of piercing hole in the CNC system

before the fulfillment

piercing hole

11

The CNC control start 1、Increase the setting of “given voltage”

move, the cutting 2、Prolong the automatic time in the CNC system

torch then begin work 3、Decrease the setting of over-voltage

4、Check the situation of automatic signal or cornering signal

of CNC system

12

Plasma arc out after 1、 Delay-time is too long

the arc transferring

and piercing hole

13

When do the IHS, the 1、Time of HIS is too short

cutting torch touch the 2、Induced lead connect with protection badly

steel plate but no

movement upwards.

14

Cutting torch still 1、Bad checking cable and contact of the Torch Retaining

press the steel plate Cap

downwards and no 2、Proximity switch is damaged

arc-producing

3、“WORK” in the high adjusting is bad connection with

earth

22