State:

A、

The TORCH RETAINING CAP port on the Isolation-IHS plate connect to the

Torch Retaining Cap directly through pressing-wire hole(label: TORCH RETAINING

CAP).

B、 The WORK port on the Isolation-IHS plate connect to the material-shelf

directly through pressing-wire hole(label: WORK).

C、

GND must be linked with earth perfectly, the area of earth lead must

exceeds 4 mm².

D、 When the Plasma without HF arc, the WORK and GND can be linked with each

other directly.

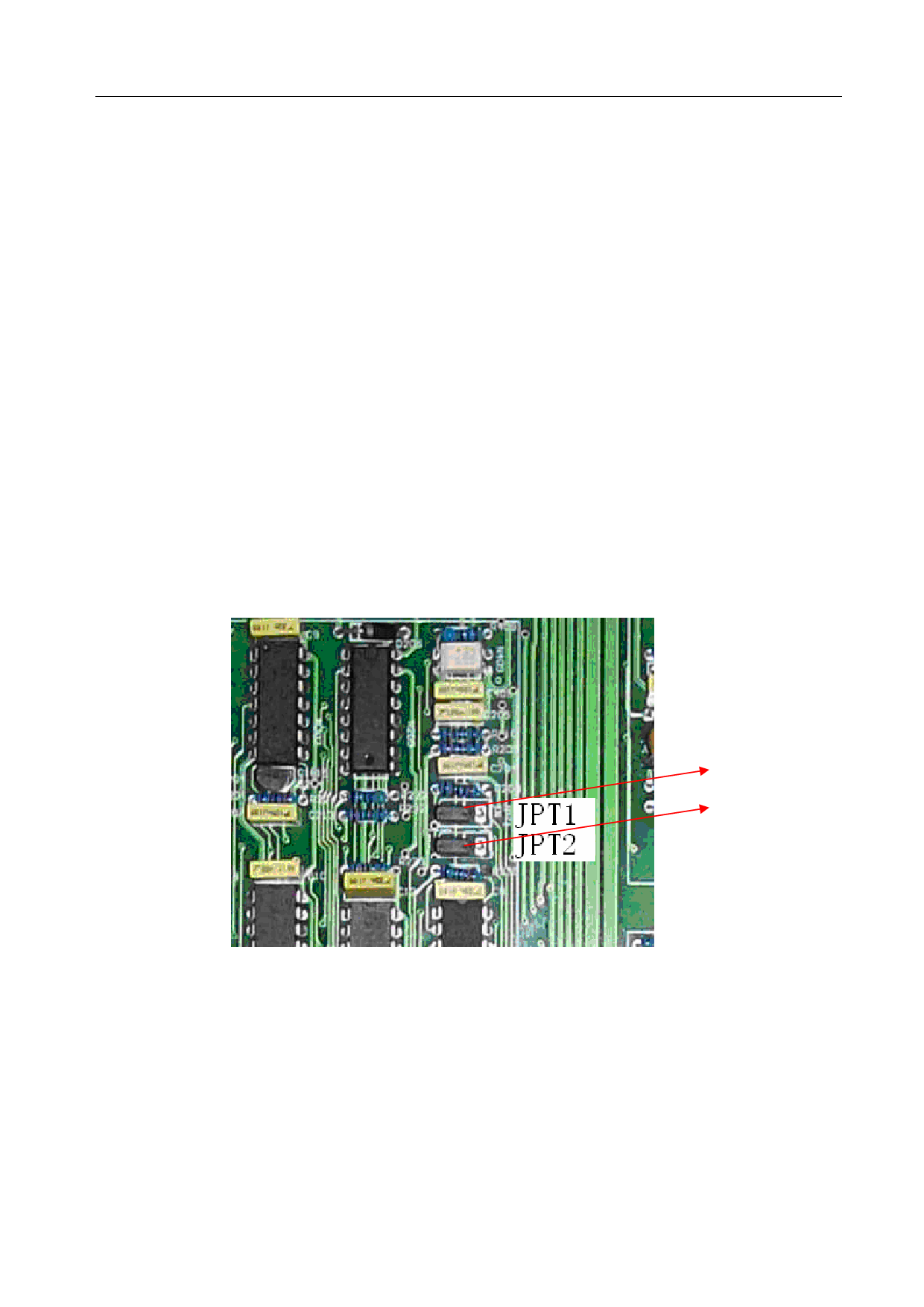

E、 Connect the JPT2 on the controlling plate to PNP when you adopt the method

of Torch Retaining Cap IHS. As Figure 5 shows(JPT1 was selected the mode of

IHS ,JPT2 was selected the type of Proximity Switch )

JPT1

JPT2

Figure 5:JPT1 Setting of Slip Wire

Working Process of Torch Retaining Cap IHS: After the high adjusting machine

receive the arc signal from the CNC system, the cutting torch come down immediately;

when the protection reach the steel plate, the high adjusting machine receive this signal

then control cutting torch to a setting height, when it finish, the high adjusting machine

control the Plasma arc automatically. You can adopt the touching-arc Plasma also HF arc

13